Balancing the washing machine drum

Balancing the drum of an automatic washing machine is essential to minimize noise and vibration during operation. Imbalance significantly reduces the lifespan of your "home helper," preventing the machine from being used at night and causing significant inconvenience even during the day.

Balancing the drum of an automatic washing machine is essential to minimize noise and vibration during operation. Imbalance significantly reduces the lifespan of your "home helper," preventing the machine from being used at night and causing significant inconvenience even during the day.

To avoid this problem, it's important to install your washing machine correctly and use it according to the manufacturer's recommendations. If it malfunctions, you can balance the washing machine drum yourself. We'll explain how to do this and what might cause this type of malfunction.

Why does bad balance occur?

There can be many reasons why a washing machine might be out of balance. Often, they're trivial and can be fixed in just 5-10 minutes. Sometimes, the problem is more serious and can be more difficult to fix on your own. Let's explore the possible causes of a washing machine malfunction.

- The user is violating the equipment operating instructions. This can include either exceeding the permissible load weight or, conversely, washing too few items. An imbalance can also occur if the clothes are thrown into the washing machine in a lump, without being distributed across the drum.

- Unlevel installation. If you place your appliance on an uneven floor and don't adjust the feet, it will become uneven. This unevenness can lead to imbalance and other problems.

- Shock absorber failure. If one of the springs deforms, the tank will become skewed, leading to imbalance.

- Bearing assembly wear. Often, imbalance is caused by damaged bearings. Replace these components as soon as possible.

- Displacement or destruction of counterweight blocks.

- Tachogenerator failure.

- Forgotten shipping bolts inside the machine. Leaving the screws inside and running a wash cycle can damage numerous components, including the drum.

Any of the listed factors can lead to breakdown. You can guess about the imbalance by the characteristic “symptoms” – knocking, grinding and increased vibration when the machine is running. Let's figure out how to fix the problem in each case.

Incorrect installation and operation of the machine

After purchasing and connecting a new washing machine, some users are in such a rush that they forget to remove the shipping bolts. These bolts are designed to securely fasten the drum to the housing, preventing it from wiggling during transport. Starting the washing machine without removing the bolts can seriously damage your "home helper." The machine will attempt to start a wash, but will be unable to spin the drum properly, making a loud humming noise. The solution is simple: stop the cycle and remove the four shipping bolts. The key is to notice this problem early.

Another possible cause of a washing machine becoming unbalanced over time is improper installation. The floor beneath the machine must be level and solid. Ideally, the base should be tile or concrete.

Many users often neglect to level their appliances, and this is a big mistake. If the drum is crooked, adjust the washing machine. Take a spirit level, place it on the machine, and adjust the machine's feet. If your "home helper" continues to make noise and shake, the problem must be looked for internally.

Often, imbalance is caused by constant overloading of the washing machine.

Many housewives try to overload the drum, ignoring the maximum load capacity. If the drum is overloaded, the washing machine begins to reduce spin speed, which over time leads to imbalance and failure of some internal components.

The same thing happens when the machine spins almost empty—if there's just a T-shirt or sweater in the drum. This extreme condition is also harmful to the washing machine. To prevent imbalance, it is necessary to strictly adhere to the minimum and maximum permissible loading weight established by the manufacturer.

If you're certain the problem isn't caused by any of the reasons listed above, you'll need to run a diagnostic on your washing machine. This will require disassembling the appliance. We'll explain how to begin the inspection.

The shock absorber element has failed.

Broken shock absorbers can cause a lot of problems. Dampers perform an important function – they support the tank, preventing it from wobbling and hitting the body and internal components. To check the components, you need to:

- de-energize the machine;

- remove the top cover of the case by unscrewing two bolts;

- Press down hard on the tank.

If the shock absorbers are working properly, the tank will snap back into place and lock into place. If the tank continues to wobble, the shock absorbers will need to be replaced.

Depending on the model, the car may be equipped with standard shock absorbers or more modern dampers. The repair process will depend on this. The easiest way to replace the suspension springs is on the top. To do this, you need to:

- de-energize the washing machine;

- remove the housing cover;

- lift the drum and fix it in the highest position;

- Use pliers to remove the old springs and put the new ones in place.

To remove the shock absorbers or dampers directly, you'll either have to lay the car on its side or remove the front panel. This will depend on the model. Typically, the procedure is as follows:

- remove the top panel;

- remove the back wall of the case;

- remove the powder receptacle;

- remove the decorative false panel located at the bottom;

- unscrew the bolts around the perimeter of the dashboard;

- disconnect the wiring and move the control panel aside;

- remove the clamp that secures the door cuff and tuck the seal inside;

- unscrew the bolts holding the door lock and remove the lock;

- remove the screws around the perimeter of the front panel and remove the wall;

- remove the failed shock absorbing elements.

Shock absorbers and dampers are usually secured to the body with bolts or special clips. The screw must be unscrewed, and the plastic clip pressed in to release the mounting pin. Replacement of the components is carried out in a similar manner.

Problem with the engine speed sensor

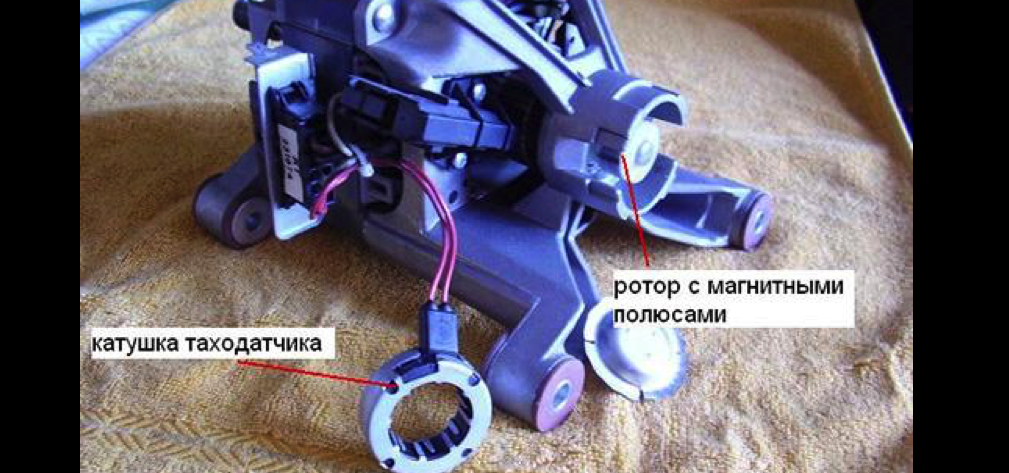

A tachogenerator is needed to measure the drum's rotation speed. If the sensor fails, the machine's intelligent system is unable to control the motor's speed. This can cause the centrifuge to spin too quickly, leading to imbalance. To test the Hall sensor, measure the resistance between its wires. A normal reading is approximately 60 ohms. If you set the multimeter to voltage measurement mode and manually spin the drum, the reading on the tester screen should increase.

If the tachogenerator fails, it will need to be replaced.

The problem may not be a broken sensor, but rather a loose connection. Simply tightening the fastener may be enough to fix the problem.

Bearing failure

Over time, the bearing assembly of front-loading and top-loading washing machines wears out. When the bearings “break down,” the machine starts to hum loudly and vibrate during operation, and significant play in the drum is observed. You can replace the parts yourself.

During the work you will need:

- screwdrivers;

- small hammer;

- punch;

- grease for seals and bearings;

- replacement parts;

- set of keys;

- WD-40 aerosol liquid.

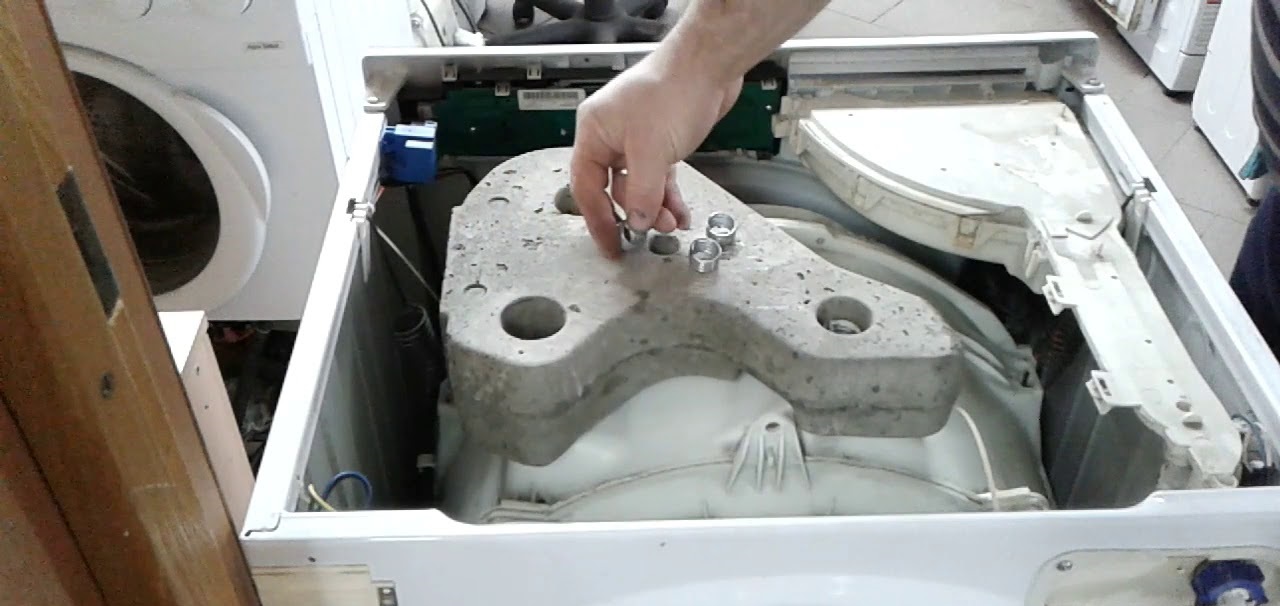

To begin, remove the top, rear, and front body panels. The first stage of the work will be the same as replacing the shock absorbers. Next, you'll need to:

- remove counterweights;

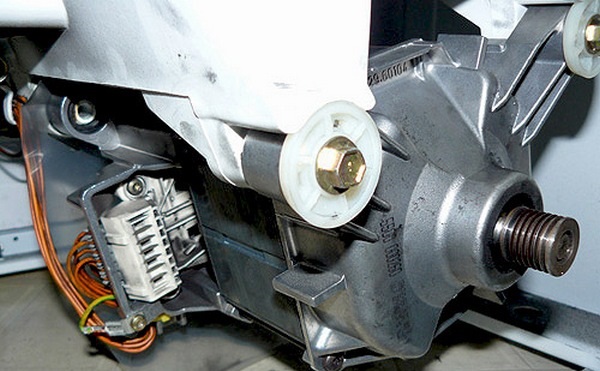

- remove the drive belt;

- disconnect the wiring from the heating element and remove the heater;

- get the engine out;

- pull out the hatch cuff;

- disconnect all sensors, pipes and wiring from the tank;

- pull the tank out;

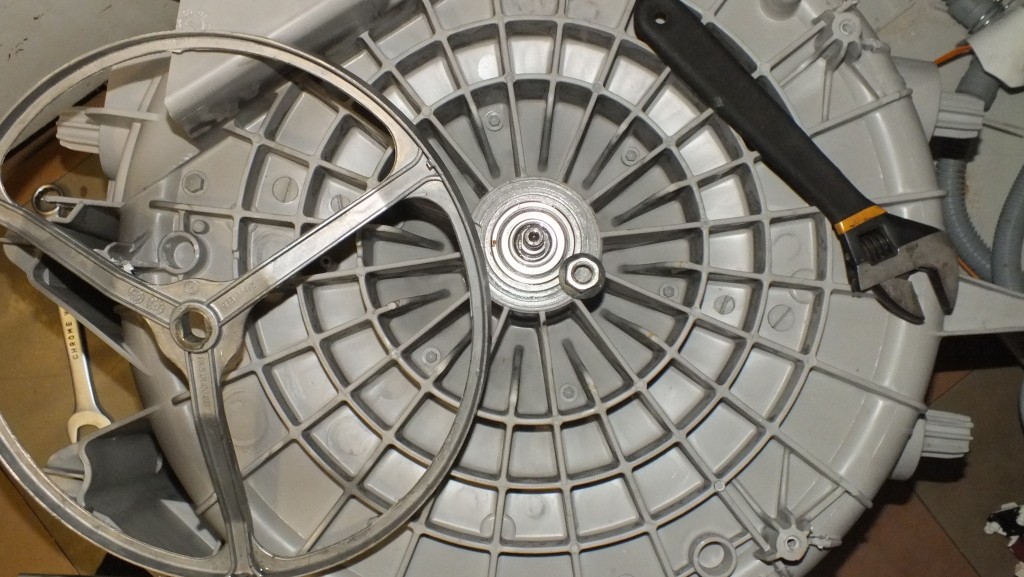

- disconnect the pulley and carefully knock out the shaft;

- split the tank in half;

- Using a punch and a hammer, knock out the broken bearings;

- clean the area from dirt, rust and old grease;

- Press in new bearings and seal.

For top-loading washing machines, the operating principle is the same: remove all components that interfere with the drum removal. The location of specific components can be found in the machine's manual.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment