Homemade concrete mixer from a washing machine

The years of total shortages are behind us; you can now buy everything you need in stores and shopping centers, from building materials to machine tools and equipment. Household concrete mixers are also readily available. The problem is, they're quite expensive, and sometimes the price isn't even the issue. For example, if you only need one for construction or renovation work, buying one doesn't make sense, and there's no one to rent it from—what to do? A solution might be to make a concrete mixer out of a washing machine yourself.

The years of total shortages are behind us; you can now buy everything you need in stores and shopping centers, from building materials to machine tools and equipment. Household concrete mixers are also readily available. The problem is, they're quite expensive, and sometimes the price isn't even the issue. For example, if you only need one for construction or renovation work, buying one doesn't make sense, and there's no one to rent it from—what to do? A solution might be to make a concrete mixer out of a washing machine yourself.

Is it worth making such a homemade product?

If you're naturally gifted and enjoy tinkering with hardware, then this article is for you. Without further ado, you can make a very useful household item very inexpensively, use it yourself, and then rent it out to friends and family. Many people are skeptical of homemade items, believing that factory-made ones are always better, but in reality, this isn't always the case. Here are the arguments in favor of making a concrete mixer yourself.

- A homemade concrete mixer costs pennies, but its benefits are exactly the same.

- A homemade concrete mixer can be made according to a custom design, for example, taking into account the size of the body or trunk of the vehicle on which this concrete mixer will be transported.

- It's easier to deal with a homemade product if it breaks while you're working on it, because you made it yourself, which means it'll be easier for you to fix.

- You'll finally find a worthy use for those old washing machine parts that are lying around in your garage, shed, or balcony.

Now that we've covered the positives, let's talk about the obstacles, and there are quite a few of them. Here are a few.

- Making a homemade concrete mixer takes time, and the time investment is quite significant.

- You need to be able to “handle iron” and have the desire to work, otherwise, it’s better not to start this business.

- You need to have an idea of the final result, an idea, and the necessary materials and components for the work.

Important! To build a concrete mixer, you'll need some understanding of electrical circuits to be able to connect its motor according to the instructions.

What materials will be needed and what to do with them?

The design of a homemade concrete mixer with a motor isn't all that complicated. It consists of three main components: the motor, which drives the concrete container, the container itself with its axle, and the base that supports the entire assembly.

When selecting materials and components, you need to have an idea of the size of the concrete mixer. A large concrete mixer has a large capacity and can mix a lot of concrete at once, but it will require a powerful motor (a washing machine motor won't do). Furthermore, such a unit won't fit in a car; you'll have to order a truck for transportation, which is inconvenient. It is better to make a concrete mixer with a small capacity, it is easier to move, and it is also easier to find parts for it.

First, let's gather the tools. We'll need a drill, a step drill bit, a hacksaw or grinder, a welder, screwdrivers and files, a set of wrenches, and pliers. Materials needed:

- Concrete mixer tank. A washing machine drum with sealed holes or the round drum of an Oka washing machine, although it's quite large, can be used as a concrete mixer tank. Some even use old cans and flasks.

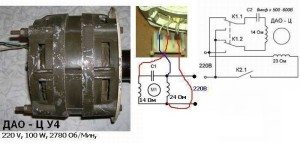

- A motor from an old washing machine. The motor is also the main component that makes the concrete mixer work. You'll have to install and connect it yourself. Incidentally, with such a motor, you can make DIY emery from a washing machine, but this will be discussed in another article.

- A 50x50 metal angle. We'll need it for the base of the future concrete mixer.

- The insides of an old washing machine, such as a Sibir, Oka, or Vyatka. Some parts from front-loading washing machines will work.

- Two wheels. You can use ones from an old wheelbarrow or cart, but they must be able to support a significant amount of weight and move easily around the site.

- A 4.5 cm metal rod. The rod must be made of durable, hardened steel, as it will act as the axle that will support the weight of the structure. The wheels will need to be mounted on it.

- Metal strips 50 mm wide and 4 mm thick.

- A piece of pipe with a diameter of 30 mm.

Important! You'll also need a large number of different components: gears of various sizes, a drive belt, bolts and nuts of various sizes, a gearbox, and more. Many of these can be found by disassembling an agitator washing machine.

Assembling the structure

First, we need to weld a strong and convenient frame from angle iron so that the structure is as stable as possible and the concrete mixer can be easily rolled from place to place. We invite you to pay attention to the “Swing” type frame. This element will serve three functions simultaneously: a strong base that won't break even under maximum load, allowing the entire structure to be easily moved, and enabling the quick removal of concrete from the mixer tank when needed. Here's what to do:

First, we need to weld a strong and convenient frame from angle iron so that the structure is as stable as possible and the concrete mixer can be easily rolled from place to place. We invite you to pay attention to the “Swing” type frame. This element will serve three functions simultaneously: a strong base that won't break even under maximum load, allowing the entire structure to be easily moved, and enabling the quick removal of concrete from the mixer tank when needed. Here's what to do:

- Cut two 60 cm pieces from the 50x50 corner – these will be the bases for two triangles.

- We cut 4 pieces of 80 cm each from the same corner - these will be the thighs of the triangles, fold the triangles and weld them securely at the corners.

- We place the triangles opposite each other, place two 50 cm long pieces of angle iron on their ends and weld them – we get a stable structure of two connected triangles.

- We take a pipe with a diameter of 30 mm and cut it so that one end lies exactly on one upper corner of the triangle, and the other on the opposite upper corner of the other triangle.

- We weld two large nuts to the vertices of the triangles, one at each vertex. The nut opening should be 1 mm wider than the pipe diameter.

- We pull the pipe through the nuts and press the ends in place so that the pipe rotates freely at the apexes of the triangles, connecting them but preventing it from slipping out. Half of the frame is ready – this is the base.

- For the top of the frame, as for the swing, we will need two pieces of 50x50 angle iron, 1.4 m long. We will lay them parallel, 40 cm from each other.

- We take three 40 cm pieces of corner and connect two parallel pieces like a ladder.

- We find the middle of our ladder, then place this middle point transversely against the movable pipe of the structure's base and weld it securely. We now have a real mini swing, since the ends of our ladder can rise and fall completely freely.

Important! To strengthen the structure, you can weld additional rods or smaller-diameter angles across the triangle's legs and other locations, creating a strong stiffening rib.

The concrete mixer base is ready. Now we need to install our container. We place our barrel at one end of the "ladder" so that most of its body touches the metal angle, and securely tack weld it to both parallel angles. The bottom of the container should face the apexes of the triangles. It is better to use the tank of the Oka activator washing machine as a container, since it already contains an activator, which can be perfectly adapted for mixing concrete.

Of course, the activator will need to be significantly modified before use. More precisely, we only need the mechanism; the plastic activator itself can be unscrewed and removed. What do we do?

- We take two steel strips 50 mm wide, 4 mm thick and 90 cm long.

- We bend them into two oblong staples.

- We thread the pre-prepared axle through the thread of the washing machine actuator so that its end is 5 cm into the washing tank, and put a nut of the appropriate size on this end.

- We drill a hole in the center of the base of each bracket, with a diameter corresponding to the diameter of the axle, and put the brackets on the part of the axle that is in the washing tank.

- We move the brackets apart so that their bases are crosswise, put a nut of the appropriate size on the axle and tack weld it so that the brackets do not slip off the axle.

What have we got? Now, if we grasp the axle of our unfinished concrete mixer from the end opposite the one in the container, we can test the rotation of our mechanism that will mix the concrete in the barrel. If everything is done correctly, the paddles, which were previously the ends of the brackets, will rotate in a circle inside the barrel. To make concrete mixing more efficient in the future, the ends of the staples should be twisted in a spiral by half a turn using pliers. (may require significant effort).

Note! There's a drain hole at the bottom of the old washing machine's tub. We won't need it now, so we can weld it shut or simply plug it tightly.

It's time to connect the motor to the opposite end of the axle of our homemade unit, unless you're planning on making a hand-held concrete mixer. Doing this yourself isn't very difficult, but you'll need to understand how to connect the motor to the power supply. You can watch the video below or find video instructions online.

Installing the motor doesn't end with just connecting it; we first need to secure it to the concrete mixer frame and protect it from rain with a rain cover. Drill holes in the corner of the ladder for the fasteners that will hold the motor. The motor housing has holes for the fasteners; align them with the drilled holes, insert bolts into the holes, and tighten them with nuts. An engine cover can be made from an old inner tube.

Installing the motor doesn't end with just connecting it; we first need to secure it to the concrete mixer frame and protect it from rain with a rain cover. Drill holes in the corner of the ladder for the fasteners that will hold the motor. The motor housing has holes for the fasteners; align them with the drilled holes, insert bolts into the holes, and tighten them with nuts. An engine cover can be made from an old inner tube.

Important! When making your own engine cover, don't try to close it completely; leave openings on the sides to prevent overheating.

The engine should be mounted on the frame so that its pulley is 2-3 cm from the edge of the axle. The pulley will have to be connected to the axle via a flange.

- We take a piece of pipe 3.2 cm long, put one end on the axle and the other on the engine pulley.

- We drill holes on both sides with a 4 mm drill to go through the flange and pulley and through the flange and axle.

- We pass bolts of suitable sizes through the holes and tighten them with nuts.

The engine is connected to the axle, now we connect it to the 220V network and check the operation of the concrete mixer. The advantage of our simple concrete mixer is that when we need to drain some concrete from the container, we simply grab the end of the "swing support" on which the engine is located and lift it up. The barrel will sink down, and the concrete will flow out. The downside of this design is that to keep the barrel at the correct angle, we'll have to place a special support, like a T-shaped spike, underneath it. But overall, this concrete mixer, built from start to finish, is quite functional.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment