What is a pressure switch in a washing machine?

A level sensor, or pressure switch, is a small device that monitors the volume of water filled into the tank. Without it, the washing machine won't draw water, receive a signal to start a wash, or initiate a rinse or drain cycle. To avoid the embarrassment of a broken machine, it's best to understand this tiny but important device beforehand. This article will cover its appearance, internal structure, operating principle, potential malfunctions, and troubleshooting methods in detail.

A level sensor, or pressure switch, is a small device that monitors the volume of water filled into the tank. Without it, the washing machine won't draw water, receive a signal to start a wash, or initiate a rinse or drain cycle. To avoid the embarrassment of a broken machine, it's best to understand this tiny but important device beforehand. This article will cover its appearance, internal structure, operating principle, potential malfunctions, and troubleshooting methods in detail.

What does the sensor look like?

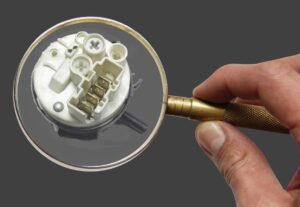

Finding the pressure switch is easy: just unscrew the top panel of the washing machine and look around. You need to find a small plastic element with a round cover - this is what this part looks like. Several wires from the control board and a long tube extending downwards connect to it. A special pressurized reservoir is also connected. The sensor's operating principle can be described as follows.

- Liquid collecting in the washing machine causes pressure to build up in the tube.

- As soon as the water and pressure equalize, the switch closes and the contacts open.

- A signal about sufficient intake is sent to the control triac.

If the pressure switch malfunctions, the system is not informed of the amount of water added. This results in underfilling or overfilling. Due to the lack of information about the tank's fullness, the machine often plays it safe and activates a pump to remove excess water to prevent leaks. Before it even reaches the tank, all the water from the water supply is immediately discharged into the sewer.

This continues until the washing machine owner stops the liquid intake and eliminates the cause of the problem.

Sensor device

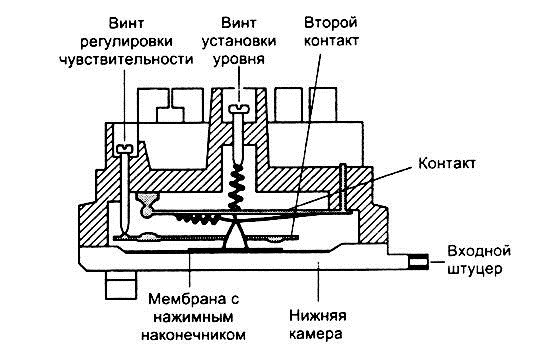

Now let's look at how a pressure switch works. The main part of the sensor is a plastic housing that holds the main structural components. These include:

- inlet fitting;

- membrane with push-on tip;

- two parallel contacts;

- sensitivity adjustment screw;

- level adjustment screw;

- thrust elements that secure two springs.

Variations are also possible. For example, electronic pressure switches have an oscillating circuit. Dual-chamber pressure switches, in addition to the lower hollow chamber, have a second chamber above, as well as an additional intermediate membrane and a pair of contacts.

Typical faults of the level sensor

Knowing what a level sensor is and what it does makes it easier to spot problems early. This allows you to fix the problem quickly and cost-effectively. Several symptoms can help you identify a malfunction.

- The cycle started with an empty drum. The system didn't receive the empty drum signal and started the wash cycle. Worse, if the heating element also turned on. This will inevitably burn out the heating element and the associated wiring, which are not designed for empty operation.

- Water intake either doesn't stop or stops immediately. The first scenario is worse, as uncontrolled filling of the tank can lead to leaks and short circuits.

- Draining is difficult. Signaling the need to drain is another reason why a pressure switch is needed. If a malfunction occurs, after the spin cycle is complete, the cycle stops with the tank full and the hatch door locked.

- No rinse. The water can't be replaced with clean water because neither the drain nor the fill function.

Modern washing machines can automatically diagnose problems and display a corresponding error on the digital display. In older models, the situation is more complex—the sensor must be constantly checked for functionality to promptly detect any malfunction. The testing procedure is described below.

How to check the part?

Before blaming the water level sensor for a stalled washing machine, you should confirm or refute your suspicion. To do this, simply check its functionality using a simple algorithm. Here's how:

- disconnect the washing machine from the power supply;

- we turn off the water;

- remove the top panel from the machine by unscrewing the two screws at the back and sliding the cover towards you;

- we determine the location of the sensor (most often it is located in the upper part of the side wall);

- we find a tube with a diameter equal to the inlet fitting;

- loosen the clamp on the pressure hose and unhook it;

- We insert the prepared tube into it and blow lightly.

If you hear 1-3 clicks, the contacts are working properly. Next, carefully inspect the housing and all adjacent wires for damage or blockages. The final step in testing is connecting a multimeter. Set the device to measure resistance and attach the probes to the terminals on the pressure switch. Everything is OK if the display changes. Otherwise, remove the component and install a new one.

Important! In some cases, the pressure switch can be adjusted by adjusting the screws, but this should only be done by service technicians.

Most often, a damaged sensor cannot be repaired. The only solution is to unscrew the screws holding the housing, cut the clamps, and disconnect all the hoses and contacts. Then, purchase a similar sensor and install it in the washing machine in its place.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment