A circular saw made from a washing machine motor

Such a useful thing as a working motor from an automatic washing machine should not be lying around idle in your garage.

Such a useful thing as a working motor from an automatic washing machine should not be lying around idle in your garage.

Any self-respecting DIYer would get itchy at the sight of such a promising detail.

In this article, we'll show you how to use this engine to make a very good, lightweight, and compact circular saw that can easily cut a 50mm board or even a 10x10 beam.

Warning! Assembling and using a circular saw yourself can be dangerous! Therefore, do not attempt this project unless you are confident in your skills and follow safety rules! This article is not a call to action. And remember, you are solely responsible for your actions!

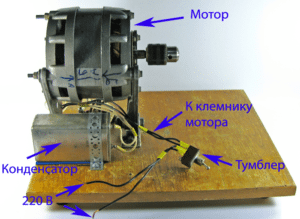

How to connect the motor?

Connecting the motor is the most important stage of the work. If you fail to connect the washing machine motor correctly, you won't be able to make a circular saw yourself. The whole difficulty is not even in the connection, but in achieving stable regulation of the motor speed; without this, the circular saw will not work properly – the disk will tear the lumber.

Connecting the motor is the most important stage of the work. If you fail to connect the washing machine motor correctly, you won't be able to make a circular saw yourself. The whole difficulty is not even in the connection, but in achieving stable regulation of the motor speed; without this, the circular saw will not work properly – the disk will tear the lumber.

The manufacturer installs a so-called tachometer or speed control sensor on the motor of an automatic washing machine. The problem is that this sensor is controlled by the washing machine's electronic module, and you can't install such a module on a circular saw, so you'll have to consider a device that will control the motor speed. Learn more about howregulate the speed of the washing machine motoris described in the article of the same name.

Moving parts

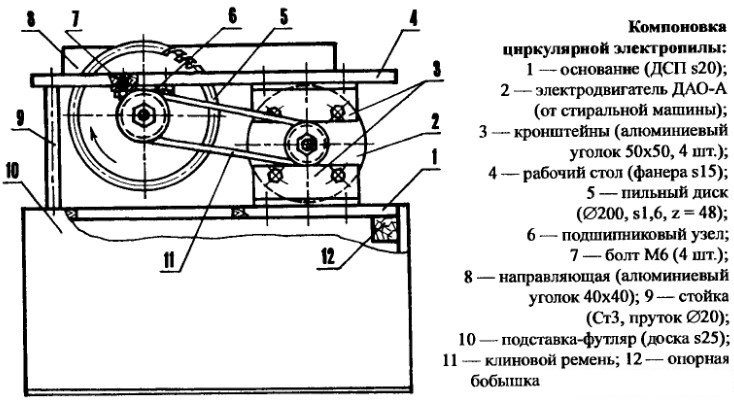

Once you've successfully connected the washing machine motor yourself and tested how it accelerates and decelerates, you can begin making your circular saw. The diagram below shows a simplified drawing of a homemade circular saw made using a washing machine motor.

The diagram can be further simplified by eliminating the bearing assembly. This is perfectly acceptable for household circular saws.

For now, we will only be interested in the moving parts of the circular saw, which will bear the main load, namely:

- circular saw shaft;

- motor shaft of automatic washing machine;

- drive belt;

- automatic washing machine motor pulley;

- Circular saw shaft pulley.

The drive mechanism should work as follows. The washing machine motor drives a shaft with a small pulley pressed onto it. A drive belt is attached to the small pulley, which transmits power to a large pulley attached to the shaft, which drives the circular saw. At first glance, everything seems simple, but when you make a circular saw, a lot of subtle difficulties emerge that have to be resolved.

- The small pulley must be machined manually, making 3-4 transverse grooves on it so that the belt clings to them and does not slip.

- The drive belt does not necessarily have to be taken from an automatic washing machine; you can take a similar part from any other appliance, as long as the belt is durable and has serrations.

- You'll need to weld a slightly larger disc onto the edge of the large pulley to create a protrusion that will prevent the drive belt from slipping during operation. It's not necessary to grind the serrations on the large pulley; the belt will engage normally without it.

- The shaft on which the circular saw will be held, as well as the nut and washer, must be reliable so that, firstly, the circular saw does not deform at high speeds, and secondly, so that the circular saw does not jump out and cause harm to the person working with the circular saw. It is better to take a ready-made shaft, washers and nut from a standard factory circular saw.

The described mechanism is designed for a 300-gauge blade. Many skeptics claim that a washing machine motor won't handle such a blade, and that it will stop at some point during operation, causing the saw to get stuck in the board. Our specialists have the following answer for these skeptics.

- Firstly, you need to know how to work with a circular saw and not push anything onto the rotating saw.

- Secondly, this circular saw will be purely for household use; it is designed for short-term work with a small amount of lumber. If you want to make a circular saw for business, then purchase special components; such equipment cannot be made from scrap parts.

- Thirdly, experience shows that quite a few DIYers use this type of equipment and are very satisfied. At least, their feedback is generally positive.

In the future, do not overload your homemade circular saw with work, and most importantly, do not let the engine run for a long time without a load.

Bed and frame

Having assembled the moving parts of the circular saw, all that remains is to make a sturdy frame and stand for our saw. In principle, the stand for a household circular saw can be made from common materials, such as a piece of thick, flat slate. Cutting a rectangle from it and cutting a hole for the circular saw is easy. However, we prefer solid construction, so we'll use a 3mm thick sheet metal for the stand and a 30mm thick angle iron for the frame.

The picture above clearly shows the components of the frame of a homemade circular saw. In this case, it's also welded, but instead of a static metal angle, special homemade stands are used for support. The stand is made of two metal pipes of different diameters, inserted into each other, allowing the saw frame to be height-adjustable.

Experts insist on a welded frame design for a circular saw, since vibration has a negative effect on static fastenings created with bolts. Although, if you don't have a welder, in a pinch, you can make a frame from angle iron, fastening them together with bolts and nuts. It's also best to weld the bed to the frame.

So, making a circular saw from a washing machine motor is entirely possible if you have experience making various DIY projects. Give it a try, and perhaps you'll gain some experience to share with our readers. Good luck!

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment