Imbalance in the Asko washing machine

All new Asko washing machines feature a useful imbalance monitoring feature. It monitors overloads caused by centrifugal force during the cycle. Therefore, if the system detects an imbalance in an Asko washing machine, the control module will stop the wash cycle and display an error code on the dashboard. Let's explore why imbalances occur in household appliances, how to correct them, and how to prevent them.

All new Asko washing machines feature a useful imbalance monitoring feature. It monitors overloads caused by centrifugal force during the cycle. Therefore, if the system detects an imbalance in an Asko washing machine, the control module will stop the wash cycle and display an error code on the dashboard. Let's explore why imbalances occur in household appliances, how to correct them, and how to prevent them.

What to do when the problem appears?

Don't call a service center until you figure out the cause of the imbalance, as you may be able to fix the problem yourself. Drum imbalance is a common problem with automatic "home helpers", but at the same time one of the easiest to fix. What to do if an error occurs?

- Try opening the door to break up the clump of clothes in the drum. Sometimes small items get caught in larger items, such as duvet covers, causing an imbalance. In this case, evenly distribute the clothes in the drum, drain the waste liquid, and restart the spin cycle. If the washing machine allows you to open the door, this will likely resolve the issue.

- If you accidentally added too much laundry and overloaded the drum, remove some items from the drum. Pay close attention to the drum load capacity, which varies across Asko washing machine models. After completing these steps, simply run the spin cycle again.

Please note that it is possible that there were too few things, because there is not only a maximum load, but also a minimum.

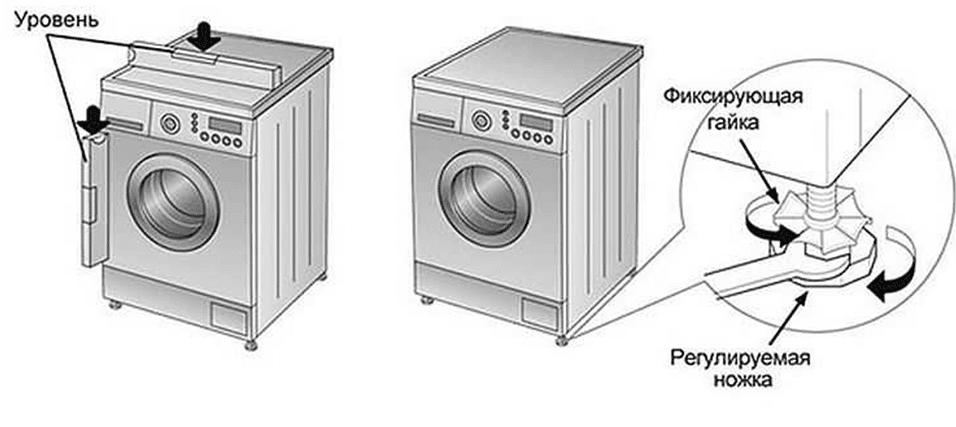

- The problem could also be caused by errors during the initial installation of the washing machine. An imbalance typically occurs when the appliance is placed on an uneven chipboard or wood surface rather than on a stable surface such as concrete or tile. Furthermore, it's crucial to level the appliance using a spirit level, as even the slightest deviation will increase vibration, especially during the spin cycle. Additionally, ensure the drain hose is positioned at least 60 centimeters above the floor, as otherwise drainage problems may occur.

These are the most common causes of imbalance, which arise due to a housewife's error during operation or preparation of the appliance. If this doesn't resolve the problem, it's likely that one or more components of the washing machine are faulty.

Why does the error appear?

What if the imbalance isn't caused by crumpled laundry or overloading? In this case, you'll need to carefully inspect the appliance for damage and installation errors.

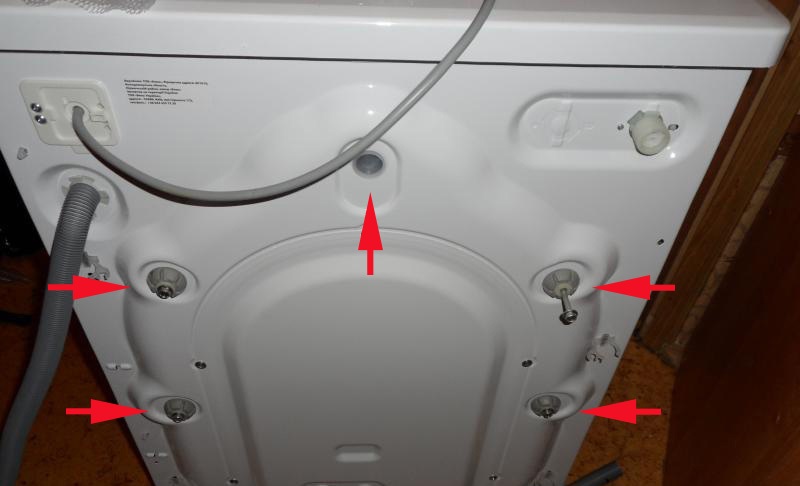

- Forgotten shipping bolts. The manufacturer installs these fasteners to ensure safe transport of the washing machine from the store to the customer's home. These bolts protect the washing machine's drum during transit, so if you run a cycle with them in place, the shock absorbers will be unable to compensate for the negative effects of the centrifugal force generated by the rotating drum. This can even cause damage to your "home helper," so shipping bolts should never be left in the machine after delivery.

Starting a wash cycle with these locks in place will void the warranty, so they must be removed before the first wash cycle.

- Incorrect installation. The Asko washing machine must be installed securely to reduce vibration and the risk of imbalance. It's best to place the machine on a concrete or tiled floor, then carefully level it using a spirit level, adjusting the feet. To improve the quality of installation, special attachments for the feet or an anti-vibration mat can be used – these devices reduce the risk of household appliances slipping during vibration. Please note that experts do not recommend placing the washing machine on linoleum, wood, or carpet.

- Damaged shock absorbers. One of the most important components in a washing machine that can eliminate vibration and imbalance is the shock absorbers. If they fail due to worn seals or loose fasteners, they will need immediate replacement. It's easy to check for the need for replacement: simply remove the top panel of the machine and press down on the drum. If the drum starts to wobble erratically instead of bouncing a few centimeters once and stopping almost immediately, new shock absorbers are needed.

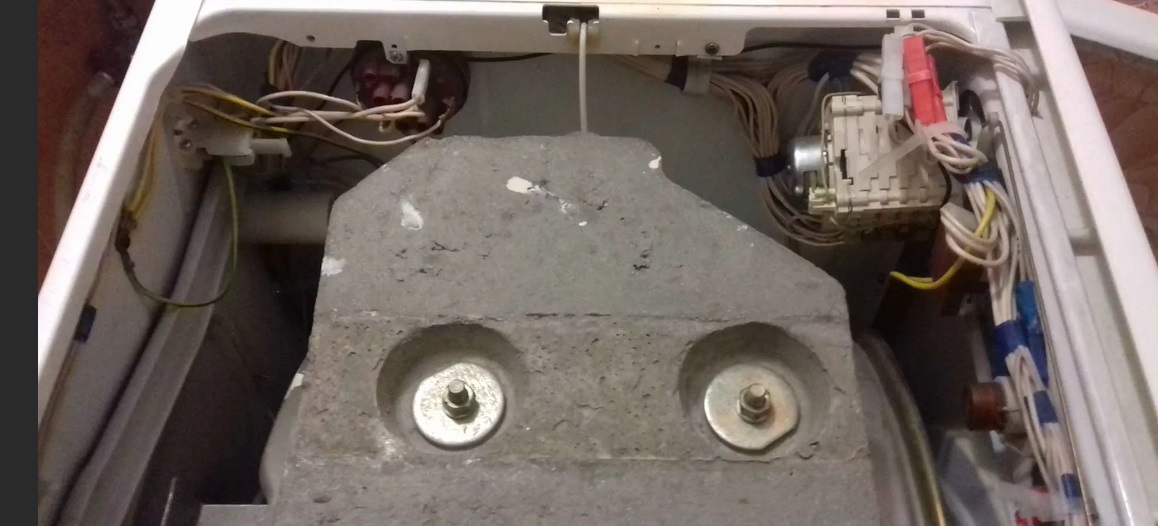

- Failed counterweights. Concrete blocks, typically placed on the top, sides, and bottom of the washing machine to ensure the drum is securely supported on all sides, also help eliminate vibration. If the counterweights are deformed or damaged, the vibration will become uncontrollable, the machine will begin to bounce violently, and the concrete blocks will bang loudly against other components of the washing machine. To check the components, remove the top or back panel of the machine and inspect the counterweights. If the retaining bolts are loose or chips or cracks have formed, the heavy concrete blocks must be carefully replaced, ensuring no damage to other components of the appliance.

Counterweights can be repaired if the cracks are not too large – to do this, the damaged areas must be generously sealed with cement mortar and PVA glue.

- A faulty bearing assembly. Finally, if the bearing is broken, you'll notice not only an imbalance, but also a slowdown in the drum rotation during operation, as well as a loud clanking noise.

If you suspect the bearings are the problem, it's best not to attempt to fix the issue yourself, as this would require almost complete disassembly of your "home helper." That's why it's easier and safer to call a repair technician to quickly restore your Asko washing machine to working order.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment