Why do you need a pressure switch in a washing machine?

Water enters and exits the washing machine via a pump and a fill valve. All washing operations are controlled by a "brain" module that receives data and issues appropriate commands. However, without a pressure switch, all the machine's efforts are in vain.

Water enters and exits the washing machine via a pump and a fill valve. All washing operations are controlled by a "brain" module that receives data and issues appropriate commands. However, without a pressure switch, all the machine's efforts are in vain.

What is this part for?

The pressure switch in a washing machine is essential for monitoring the volume of liquid in the drum. It determines the amount of water based on its pressure. Without it working properly, the control module won't turn on the water, and if it does, it pumps it out—just in case. Therefore, without a water level sensor, the washing machine is powerless.

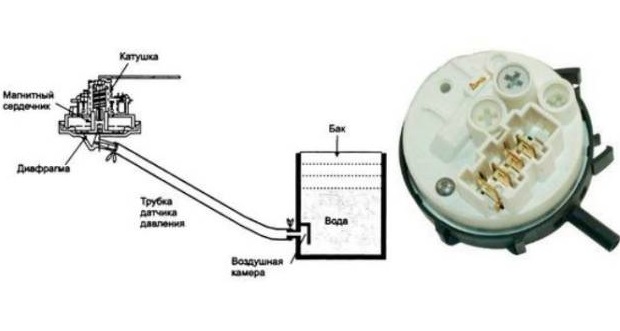

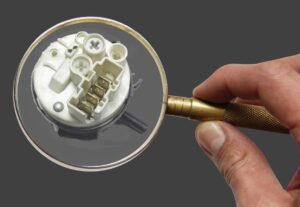

This relay, round or (less commonly) rectangular, is equipped with a hose and wires. The design of the device depends on the capabilities of the washing machine, its number of functions, and modes. Therefore, each washing machine model has its own pressure switch. There are mechanical/pneumatic and electronic relays with an oscillating circuit. The latter differ in the stiffness of the diaphragm and the stroke of the core.

The pressure switch is made of high-quality plastic and, depending on the type of machine, is located in the following places:

- directly under the lid of the case - in classic machines that have a loading hatch on the front wall;

- under the drum – in washing machines with vertical loading of laundry;

- near the back wall, below the tank – in machines with a plastic drum.

Description of the element's operation

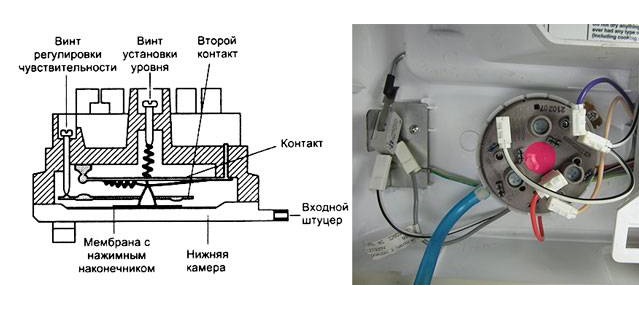

To understand how a pressure switch operates, it's important to understand its design. A typical water level sensor consists of the following components:

- magnetic/ferrite core;

- membranes/diaphragms;

- sensor in which the diaphragm is located;

- springs;

- adjusting screw;

- inductive coil, circuit board, and capacitors. The function of these components is to ensure the operability of the relay components;

- contacts;

- housings;

- The compression chamber. It's located at the base of the hose/tube connecting the chamber to the sensor. A clogged chamber is one of the causes of washing machine malfunctions.

The pressure switch operates based on the pressure of the water column on the diaphragm. Pressure is generated when liquid enters the tank through a compression chamber connected to a tube. The diaphragm, in turn, under the liquid pressure, moves the core, closing the contacts. When a certain volume of water is reached, one of the switches is activated (a relay signals this to the control module).

When the wastewater is drained, the pressure in the hose/tube decreases. The core returns to its original position, and the relay opens. A properly functioning pressure switch accurately responds to all fluid pressure readings, sending signals to the washing machine's control module. The volume of liquid dispensed for each wash cycle depends on the accuracy of its pulses. Only the machine manufacturer can accurately calibrate the sensors. Adjusting the pressure switch yourself is not recommended.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment