The washing machine motor hums but doesn't turn.

Equipment often breaks down, and the malfunctions manifest strangely: everything seems to be working, but in reality, it isn't. For example, a washing machine's motor hums, but the drum doesn't spin—the cylinder remains motionless. If everything spins manually without a problem, then there's clearly a problem with the motor. You can fix the slowdown yourself at home. Let's find out what's wrong with the motor and how to start it without calling a service center.

Equipment often breaks down, and the malfunctions manifest strangely: everything seems to be working, but in reality, it isn't. For example, a washing machine's motor hums, but the drum doesn't spin—the cylinder remains motionless. If everything spins manually without a problem, then there's clearly a problem with the motor. You can fix the slowdown yourself at home. Let's find out what's wrong with the motor and how to start it without calling a service center.

What happened to the car?

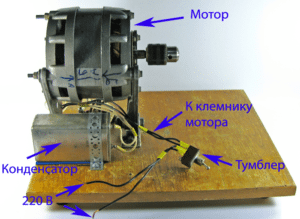

There are several possible causes for a washing machine motor not starting or not reaching the set speed. However, the most common cause is the capacitor, which is responsible for the operation of the asynchronous motor. It is this capacitor that is most affected by inrush currents, which ultimately leads to its failure.

The washing machine capacitor cannot be repaired; the part will have to be replaced with a new one.

To restore the engine's operation, you need to access the control board and replace the burnt-out capacitor. But before diagnosing the module, it is better to make sure that the part is broken by evaluating the behavior of the washing machine several more times. The following "symptoms" will indicate a malfunction:

- the engine hums, works, but the drum does not spin up to the speed set by the program;

- the machine does not respond to pressing and holding the start button;

- the LEDs on the dashboard are flashing randomly;

- the drum rotates only at one speed or does not rotate at all.

If you notice any of the above signs, the capacitor is broken. It cannot be repaired; it must be replaced with a new one.

Getting to the capacitor

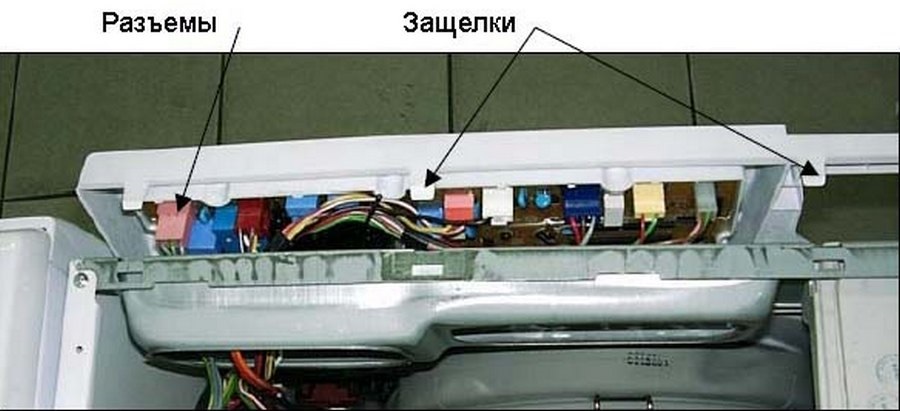

To inspect the capacitor, you need to access it. This isn't easy, as the device is located on the control board—the back of the dashboard. Removing the dashboard requires partially disassembling the washing machine. Here's how:

- we disconnect the machine from communications;

- we take out the powder receptacle by pulling it towards ourselves;

- we unscrew the bolts “hidden” behind the tray;

- remove the top cover of the washing machine;

- loosen a few more bolts around the perimeter of the dashboard;

- we unclip the fasteners holding the dashboard on top and on the sides;

- We detach the panel from the body without disconnecting the wiring.

It is not recommended to completely disconnect the instrument panel from the washing machine; only professionals can reconnect the wires. It's best to leave the wiring alone, turning the board to the correct side and placing it on top of the washing machine. Afterwards, we find the capacitor on the module and begin diagnosing it.

Characteristics of capacitors and their testing

To diagnose a capacitor, you'll need a special device—a capacitance meter. Sometimes, this measurement can be performed using an advanced multimeter. The procedure is as follows:

- discharge the part (the capacitor terminals should be short-circuited);

- disconnect any of the terminals;

- set the multimeter to the capacitance measurement mode;

- touch the capacitor terminals with the multimeter probes;

- compare the results on the device with the norm.

A capacitor's capacitance represents the energy a device can store internally. It also reflects the magnitude of the inrush currents that freely flow through the device. These are measured in farads with multiple suffixes, most commonly "nano" or "micro." Typically, values range from 1-100 microfarads (μF). If the value deviates from the norm, the component stops working, and the washing machine's motor stalls.

The multimeter also measures the nominal voltage. It is indicated on the part's body and reflects its service life:

- 400 V - about 10 thousand hours;

- 450 V – up to 5 thousand hours;

- 500 V – up to 1 thousand hours.

If the capacitor has exhausted its lifespan or burned out, it needs to be replaced. The old device is desoldered and replaced with a new one. Then, the updated board is reinstalled, the machine is reassembled, and a test run is run. Did the drum spin? Then everything was done correctly.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment