Electric cultivator from a washing machine engine

Folk "Kulibins" (do-it-yourselfers) never cease to amaze internet users with their imagination, inventing various useful designs from parts of old or broken household appliances. These craftsmen have even found a use for washing machine motors, which have become the basis for many household appliances. Most of them are simple and primitive, and can be constructed quickly, without much effort or expense. However, there are also more complex designs, the assembly of which requires certain skills and abilities. A striking example is an electric cultivator made from a washing machine motor, the assembly instructions for which are provided below.

Folk "Kulibins" (do-it-yourselfers) never cease to amaze internet users with their imagination, inventing various useful designs from parts of old or broken household appliances. These craftsmen have even found a use for washing machine motors, which have become the basis for many household appliances. Most of them are simple and primitive, and can be constructed quickly, without much effort or expense. However, there are also more complex designs, the assembly of which requires certain skills and abilities. A striking example is an electric cultivator made from a washing machine motor, the assembly instructions for which are provided below.

What is a homemade cultivator?

Every gardener knows the challenges of cultivating a garden, especially one larger than the standard 600 square meters. The lion's share of the work falls on preparing the soil for planting seedlings and cleaning it up at the end of the gardening season. A homemade electric cultivator can significantly simplify these tasks. Its uses are wide, and every gardener will quickly appreciate the advantages offered by such a design.

Before assembling the device, it's worth familiarizing yourself with the types of cultivators, their structure, differences, and features, as well as their purpose and operating principles. Devices come in the following types:

- Electric ones – they do not harm the environment and are quite economical, but their use is limited by the distance to the nearest power outlet. Best suited for work on small garden plots;

- fuel-powered – run on gasoline or diesel fuel, are not considered environmentally friendly equipment, but can be used autonomously.

Since a broken washing machine leaves the home handyman with an electric motor, it's worth considering building an electric cultivator, which requires access to a power source. Its indispensability will be appreciated by summer residents and those living in private homes.

The design and assembly of an electric cultivator

Assembly takes no more than two days, provided the necessary preparation has been completed and all necessary parts are available. To build your own electric cultivator, you'll need:

- washing machine motor;

- gearbox;

- "sprockets" and a chain (can be removed from a child's bicycle);

- bearings;

- cultivator blades (you can also make them yourself using welding and car springs);

- corners;

- wheels;

- cable (it is advisable to take a wire at least 50 m long);

- a sheet of iron from which the engine protection will be created.

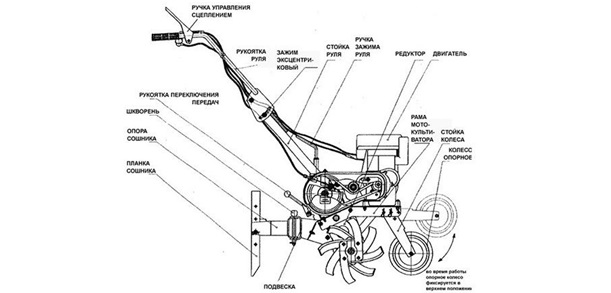

Once assembled, the resulting structure will look like a metal frame with wheels on the sides. The central section will house the motor, connected to the blades by a chain and sprockets. It is recommended that the knives themselves be made from sharpened and connected machine springs, but any other material that is at hand will do. The knives should be placed as follows:

- the sharpened part is located on the side of shaft rotation;

- the distance between the knives is not less than 5 cm;

- The angle of placement is 120 degrees.

It is recommended to attach the starting mechanism to the handles with which the device will be controlled.

The frame of the device is made only after the main internal parts of the cultivator are connected together. If you make the protective system in advance, you may not get the dimensions right.

The gearbox, whose output shaft already has the blades attached, is connected to the transmission mechanism and welded to the motor housing. The latter is secured to the frame with brackets, bolts, and clamps. The axle holding the wheels is attached to the motor's central axis. Finally, the handles are welded to the frame, and the electrical cord and plug are connected.

What are the advantages and disadvantages of an electric cultivator?

A home-built design for gardening has both advantages and significant disadvantages. The advantages of an electric cultivator include:

- low cost: most of the parts can be easily found by a home inventor in a garage or shed;

- environmental friendliness – all devices powered by electricity do not emit polluting emissions into the environment;

- self-assembly – knowing how the structure is constructed, its advantages and disadvantages, it will be easy to prevent or fix breakdowns;

- Possibility of modernization – a self-assembled structure can be easily modified and supplemented with necessary and effective parts that increase its performance.

The disadvantages of cultivation equipment created at home based on descriptions and advice from the Internet include:

- lack of necessary skills – the device is quite complex, so its creation requires certain knowledge, skills and appropriate equipment (for example, a welding machine);

- Low reliability – like any technology created without appropriate production equipment, it can be quite dangerous.

The limited area covered can be easily overcome by extending the cord: you can always purchase an industrial-strength cord or make your own, adjusting the cord length so the electric cultivator can easily reach even the most remote areas of the garden. So, in our opinion, these shortcomings are easily livable.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment