What is the difference between electronic and mechanical controls in a washing machine?

Washing machines with manual controls are becoming less common in stores, but people still debate which is better and more reliable: manual or electronic. Moreover, some technicians claim that older manual controls are much more durable than modern electronic technology. It's important to find out which side is right. Let's explore the differences between electronic and mechanical controls and which will last longer. We'll compare the two options across all criteria.

Washing machines with manual controls are becoming less common in stores, but people still debate which is better and more reliable: manual or electronic. Moreover, some technicians claim that older manual controls are much more durable than modern electronic technology. It's important to find out which side is right. Let's explore the differences between electronic and mechanical controls and which will last longer. We'll compare the two options across all criteria.

Comparative characteristics of control types

To determine which control type is better, it's necessary to consider both options. Let's start with manual transmission, whose main advantage is reliability. Mechanical switching is carried out using timers, thanks to which the rotary switch moves at a certain speed. Contacts close, activating or deactivating the designated functions. The circuit is simple and therefore reliable. However, there is a drawback: a large number of components are constantly rotating, which accelerates their wear. Parts wear out, break, and require repair more frequently.

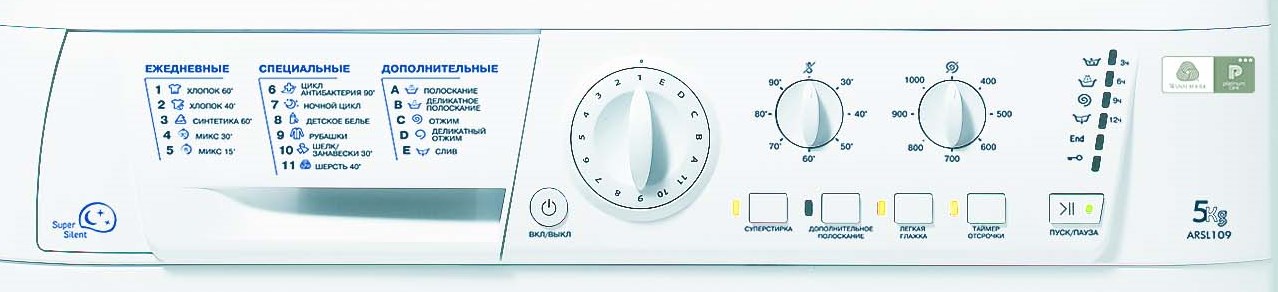

Electronic controls aren't exactly simple; on the contrary, they're quite complex and confusing. But this complexity doesn't affect the user: thanks to a multitude of buttons and controls, using an automatic transmission is easy and straightforward. Simply glance at the instrument panel, read the icons, and press the desired button. Besides convenient and intuitive settings, modern electronics offer the following advantages over manual transmissions:

- minimum moving parts, which reduces the likelihood of system wear;

- the presence of many additional functions that simplify washing and improve the quality of washing (hair removal, intensive rinsing, acceleration);

- equipping the machine with special sensors that automatically calculate the amount of water and powder collected, as well as the temperature and duration of the cycle;

- the washing process is clearly visible thanks to the display (it shows the cycle stage, duration and selected settings);

- Increased safety, as the electronics are capable of responding to emergency situations, shutting off the machine in the event of leaks, excessive foaming, and imbalance (thanks to sensors, the washing machine detects the malfunction and stops it);

- self-diagnostics (all units and parts are connected to the “brain” – the control board, so in case of failures the module detects the breakdown and displays the error code on the display).

Mechanics are considered more reliable, electronics are more convenient and safer.

Electronically controlled washing machines also have a drawback: they are sensitive to sudden voltage fluctuations. A sudden power outage or surge can cause the system to freeze, even leading to damage to the control module. Reflashing, repairing, or replacing the control module is expensive; sometimes it's more cost-effective to buy a new washing machine. However, an alternative is to install a special stabilizer into the power supply, which will smooth out the power supply and protect the washing machine from failure.

Comparing the advantages and disadvantages of mechanical and electronic controls, we can conclude that electronics clearly win. If a washing machine has a control board, it's more convenient, simpler, and safer to use. That's why it's practically impossible to find manual controls in stores these days.

Why did old mechanical sewing machines last longer?

Old manual washing machines last longer than their modern counterparts—that's a fact. But it's not a matter of mechanics and electronics, but rather mass production and market conditions. The first washing machines took a long time to manufacture, were built to a high standard, and were expensive. They were assembled from robust components under strict control and constant testing. No expense was spared: the tub was made of stainless steel, the counterweights of cast iron, and the body of expensive plastic. The end result was a durable "home helper" for a hefty price.

Competition is currently forcing manufacturers to reduce costs and speed up production. Washing machines are inspected by robots, not humans, and the cheapest materials possible are used, including concrete counterweights and plastic tanks. Even the body is made of thin plastic—all to reduce costs. Mass production also plays its part: more equipment is assembled, and the percentage of defective products increases. However, modern washing machines cost several times less than their predecessors: the average price is 10-12 thousand. If such a unit lasts even three years, it will fully recoup its cost.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

How do I remove music? It's impossible to listen to!