A washing machine motor for a bicycle

Among the unusual uses for a washing machine motor, the most unusual is perhaps turning it into a bicycle motor. A bicycle motor made from a washing machine sounds more than extravagant, but it looks absolutely exceptional. Read this article to find out whether it's possible to make this "technical artifact" and how to do it. Be warned, this project is technically complex and quite expensive, so if you're unsure of your abilities, don't attempt it.

Among the unusual uses for a washing machine motor, the most unusual is perhaps turning it into a bicycle motor. A bicycle motor made from a washing machine sounds more than extravagant, but it looks absolutely exceptional. Read this article to find out whether it's possible to make this "technical artifact" and how to do it. Be warned, this project is technically complex and quite expensive, so if you're unsure of your abilities, don't attempt it.

Drive mechanism

Before you begin converting a regular bicycle into an electric bike, evaluate the technical potential of your iron horse from the outside. The bicycle must have a strong enough frame, as it must, at a minimum, support the weight of the rider and the weight of the equipment that will be mounted on it. If everything is in order, you can begin to modify the bike and install a washing machine motor, drive mechanism, control system and power sources on it.

Let's start with designing and installing the drive mechanism components. It's important to note that to build a homemade electric bike from an old washing machine motor, we'll need a fully-fledged metal workshop. Or at least a lathe, a drill press, a welding machine, and a substantial supply of materials and tools, including a fairly spacious room for experimentation.

The drive mechanism will consist of the following elements:

The drive mechanism will consist of the following elements:

- modified bicycle hub;

- large pulley;

- drive belt from a washing machine;

- small engine pulley

- engine shaft.

The most difficult part here is probably making the large pulley. Finding a stock part that's the right size is practically impossible, so we'll have to make one ourselves.

- From a steel sheet (2 mm), cut out a perfect circle.

The recommended pulley diameter is 22 cm, but if the lathe can cut a circle of a larger diameter, then make it larger, the more reliable the drive mechanism will be.

- We drill small holes in the hub of the rear bicycle wheel, between the spokes. We drill similarly located holes in the steel circle.

- We drill large holes along the edges of the steel circle, simply to reduce the weight of the part. As noted above, the entire equipment, including the rider, will weigh a lot, and we need to reduce the load on the bicycle frame as much as possible, saving at least a few kilograms.

- Now comes the crucial step: weld a 20x4 mm steel strip to the edge of the disc. This should be done by gradually bending the metal strip along the edge. This is not the easiest task, because the welded joint must be perfectly smooth.

- After this, we load the part into the lathe and process it again, removing all unevenness and roughness.

- So, our part has been transformed into a fully functional pulley. Now all that's left is to paint the main part of the drive mechanism and bolt it to the rear bicycle wheel.

Important! The thickness of the large pulley will prevent the bicycle wheel from rotating after installation, as the part will interfere with the frame. Depending on the bicycle's design, the frame will need to be either bent or otherwise modified.

Frame modification

We've made the large pulley and adapted the rest of the drive train components. Incidentally, the rest of the drive train components don't need to be modified. The small pulley is already attached to the washing machine motor shaft, and the drive belt is also in place, so we can move on to modifying the bike frame with a clear conscience. When modifying the frame for a new electric bike, we must take into account that the motor must be positioned as rigidly as possible. To do this, we do the following.

- If the bike has a standard luggage rack, we weld additional cross tubes to it to strengthen the structure.

- If a trunk is not provided, then you need to weld an engine mount from pipes, similar to what is shown in the figure below.

- New frame parts need to be sanded, painted and dried.

Important! When welding the motor frame, consider the motor mounting height. The distance between the small motor pulley and the large pulley on the bicycle wheel must be ideal for belt tension.

We continue assembling the e-bike. We install the motor on the frame, attach the rear wheel with the pulley attached, and check the wheel's rotation. We tighten the drive belt and give it a gentle spin by hand, checking for slippage. If everything is OK, we begin connecting the washing machine motor and setting up its independent power supply.

Motor power supply organization

About that, How to connect a washing machine motorWe've written and discussed numerous times to make it work. So, we won't dwell on this issue again and will instead move on to organizing the autonomous power supply for our brushed motor. Otherwise, our homemade electric bike will continue to be powered by leg power.

About that, How to connect a washing machine motorWe've written and discussed numerous times to make it work. So, we won't dwell on this issue again and will instead move on to organizing the autonomous power supply for our brushed motor. Otherwise, our homemade electric bike will continue to be powered by leg power.

First, let's figure out whether a washing machine brushed motor can run on DC current. After all, the batteries that will be the main power source for the electric bike motor produce DC current, while the washing machine and its components operate on AC current (a typical 220V household power supply). It turns out there's no problem with this; in fact, a washing machine motor runs much better on DC than on AC, which, of course, is a plus.

Let's select suitable batteries. This can be challenging, as we'll need several fairly large batteries, which are difficult to mount on the bike due to their size and weight. The optimal option is eight compact 12-volt motorcycle batteries, which together produce a voltage of 96V. But there's a problem: even these batteries take up a lot of space and weigh quite a lot, so it's unclear how to fit them onto the e-bike frame.

After much deliberation and a series of unsuccessful experiments with battery boxes, it was decided to distribute the batteries evenly throughout the frame, hanging them all over the electric bike like a Christmas tree with toys.

This technical solution added problems.

- Firstly, as you can see in the picture above, the bicycle frame had to be reinforced once again to withstand the additional load. This, unfortunately, led to the fact that the weight of the “iron horse” increased once again, but nothing can be done about it.

- Secondly, 8 separate battery mounts had to be welded to the frame to ensure they could be securely fastened.

- Thirdly, I had to literally hang the entire frame with wires to connect the batteries to each other and to the engine.

- Well, and fourthly, I had to once again improve the aesthetics by repainting the bicycle frame almost completely.

Control unit

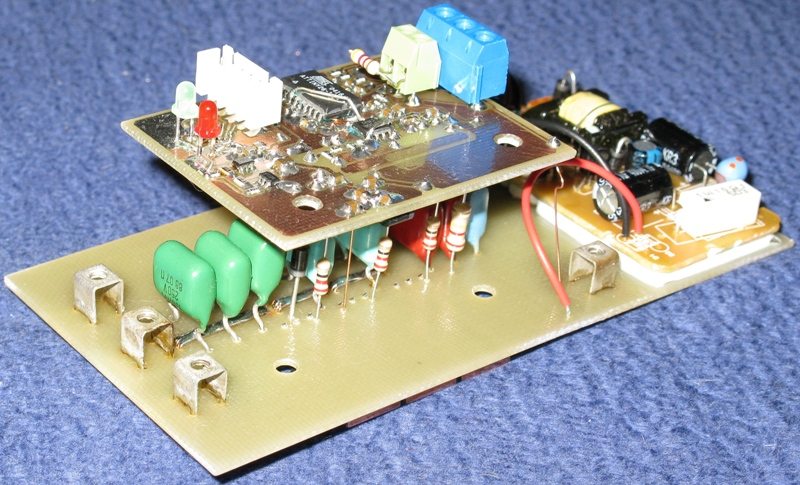

There are still a number of technical challenges we haven't yet considered—how to control the motor speed, how to prevent the current from reaching its limits when starting the e-bike and accelerating, and, finally, how to monitor the battery charge while riding. A control unit for the e-bike, which we need to assemble, will help resolve these issues. We'll need:

- 32.5 kHz step-down converter.

- Variable resistor.

- Microcontroller ATtiny26.

- Measuring resistor.

- Microcircuit IR2127S.

- Three power transistors of the IRFB33N15D type.

- Three diodes of type 10CTQ150.

- Mobile phone charger.

- DC-DC converter P6AU-1215ELF.

- Red and green LEDs.

- Machine 6A.

- Plastic case of suitable dimensions.

- Metal radiator from a computer motherboard.

We won't describe the control module assembly process, and there's no need, as all the necessary information is provided in the diagram above. All you need to do is read the diagram, understand it, and replicate it on several printed circuit boards. The result should look something like this.

The board must be placed in a compact, waterproof plastic case, with a radiator screwed to the bottom.

We couldn't find a suitable housing for the module, so we had to use what we had. To activate the control module, you need to turn on the car's automatic transmission and turn the throttle, which is the variable resistor attached to the e-bike's handlebar. After this, the motor will gradually accelerate, and a green LED on the module will light.

If the batteries are completely discharged or their capacity is insufficient, the red LED will light up, after which the circuit will be de-energized after a few seconds. You'll have to travel on foot until you can recharge the batteries.

Tests and their results

It was time to test the "hellish machine" that had cost us so much time, effort, and money. We approached the testing with no less meticulousness than we would have done when building a homemade electric bike, conducting it in three stages:

- Driving on a normal, relatively flat road (half asphalt, half dirt road) at a speed of 18 km/h.

- Driving on smooth asphalt with small climbs and descents at a speed of 25 km/h.

- Driving at maximum speed on smooth asphalt without ups and downs.

As a result, in the first test, accelerating to 18 km/h and maintaining that speed, I was able to travel 27 km on a single battery charge on dirt roads and broken asphalt. Leg strength was practically not used. There were no ups or downs along the way.

Riding an electric bike on smooth asphalt with small descents and climbs at a speed of 25 km/h, I managed to set a record – 19 km on a single battery charge. AndFinally, the maximum speed tests showed that our homemade electric bike is capable of accelerating to 30-35 km/h, This is, of course, on smooth asphalt, without descents or ascents.

Please note: The weight of the rider who tested the bike was 96 kg.

It's worth noting that if we assist the engine by pedaling, we can relatively easily reach a top speed of 45-50 km/h, and with some effort, we can even reach 60 km/h. However, the batteries drain faster, after about 10-15 km of such a sprint.

In conclusion, building an electric bike from a washing machine motor yourself will require at least several months, a workshop, a ton of effort and patience, and a fair bit of money. Incidentally, we spent about $700 on this project, even without having to buy the bike or parts from an old washing machine. If you're determined to build your own electric bike, go for it—we wish you the best of luck!

Interesting:

12 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

So what was the $700 spent on then?

Wouldn't it be easier, given the weight, to install a compact gasoline generator, squeeze out all the engine power, and use the brains from a washing machine?

It's easier to install a chainsaw engine, for example, rather than a generator.

For 700 bucks you can buy a motorized wheel with all the accessories, it will even be cheaper.

The large pulley, on the contrary, should be placed on the engine, and the small one on the wheel.

If you do this, the engine will run under load.

How awful. For that kind of money, it's easier to buy a ready-made hub motor, and eight batteries are quite expensive.

In fact, such things are done for the soul. The author ruined the bike because he wanted to be creative. But in my opinion, lithium-ion batteries are better. They can be placed in a tube like AA batteries and the voltage raised to 170 volts. This will also increase the watt-hours. The rear wheel pulley should also be enlarged, or an angle grinder should be used. It has a gearbox and the same motor type. It will also run on DC. Just use a PWM regulator instead of a current stabilizer. This will avoid current loss due to heating of the key element. Overall, I think the author relied on what was available. By the way, the drive can be made for the front wheel to avoid damaging the rear one. And an overrunning clutch should be installed near the wheel hub to avoid mechanical losses.

It’s simpler: 12-volt battery – 220 inverter – engine – additional circuits – ready.

Why not use lithium batteries?

It's even easier to avoid loading your bike with all that junk and just use your leg muscles. Then your mileage is limited only by the amount of alcohol you have to maintain your energy and relieve the stress of high speeds.

And a trailer with a refrigerator for snacks.