Homemade lawn mower with an electric motor from a washing machine

A lawn mower with a washing machine engine sounds more than a little strange at first glance. But if you think about it, there's nothing strange about it. A lawn mower is essentially a fairly simple device, yet it's incredibly expensive in the store. It's not so much a matter of money, but rather a matter of principle. If you're a seasoned DIYer or aspiring to be one, why pay someone to buy you a ready-made lawn mower when you can build one yourself, especially since your garage is stocked with the necessary parts?

A lawn mower with a washing machine engine sounds more than a little strange at first glance. But if you think about it, there's nothing strange about it. A lawn mower is essentially a fairly simple device, yet it's incredibly expensive in the store. It's not so much a matter of money, but rather a matter of principle. If you're a seasoned DIYer or aspiring to be one, why pay someone to buy you a ready-made lawn mower when you can build one yourself, especially since your garage is stocked with the necessary parts?

About the functionality of the homemade product

Some might say, "Ugh, a homemade lawn mower is unsafe, and it's less effective than a brand-name product!" In reality, these assertions are nothing more than the prejudices of slackers who are afraid to pick up a screwdriver or pliers, let alone anything more serious. If you do everything right, a homemade lawn mower will be no worse, and in some ways even better, than factory models – certainly in terms of price.

Some might say, "Ugh, a homemade lawn mower is unsafe, and it's less effective than a brand-name product!" In reality, these assertions are nothing more than the prejudices of slackers who are afraid to pick up a screwdriver or pliers, let alone anything more serious. If you do everything right, a homemade lawn mower will be no worse, and in some ways even better, than factory models – certainly in terms of price.

The lawn mower's power will be sufficient to mow the grass without any problems, and the body can be made very compact, making such a homemade device easier to store in the future. Safety issues are also questionable, as even a factory-made lawn mower can cause injury. Much depends not on the device itself, but on the person using it.

The homemade lawn mower, the design of which we will propose in this publication, is no more dangerous than equipment from leading global companies.

Necessary parts and tools

So, if you're determined to build your first lawn mower yourself, remember to gather the necessary parts and tools before you start crafting. First, let's talk about materials.

- A brushed motor from an old washing machine. This is the main component of a lawn mower. Experts recommend choosing the most powerful motor possible. It’s better not even from a washing machine, but from a Soviet-style centrifuge.

If you don't have a powerful engine, no problem, the lawn mower will still be quite functional.

- Any sturdy, small wheels. Those from strollers or wheelbarrows will do. If you don't have any wheels at home, you can cut some out of plastic profile sheets.

- An old lid from a large metal pot or a sheet of steel, at least 3-4 mm thick and 600 x 600 mm (or approximately that size), is suitable. Some people use old shallow steel basins or large bowls as a base; this is a matter of personal imagination, but the main thing is that the base is sturdy and not too deep.

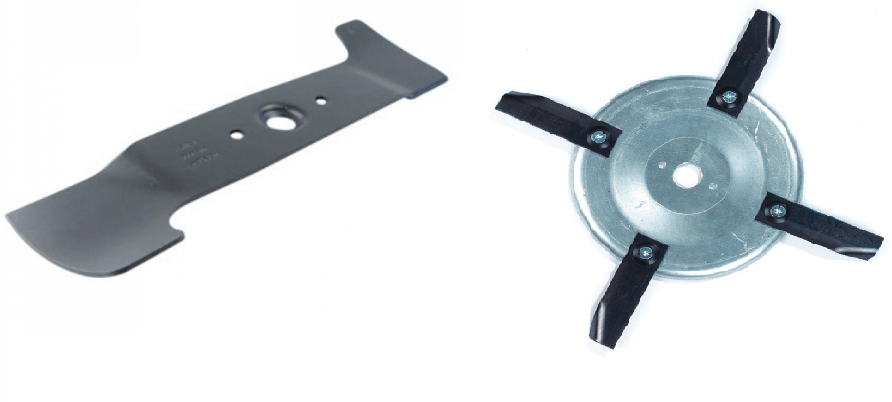

- Blades or cutting discs from a factory lawn mower. Even if you are making a lawn mower yourself, it is better to use factory-made consumables.The higher the quality of the lawn mower blade or disc you buy, the fewer problems you'll have in the future. The decision on whether to install a blade or disc on your lawn mower is entirely up to you.

- A thin profile pipe is used to make a lawn mower handle. Anything suitable can be used here. You can even make a handle out of a water pipe, although this will add significant weight to the structure. When our craftsmen built their own lawn mowers, they repurposed the handles from an old wheelbarrow, connecting them using a curved pipe.

- Small pieces of steel angle iron, which we'll use to make the engine frame. You can use any kind of angle iron, thick or thin.

- A three-wire copper wire with insulation and a plug. Since our lawn mower will be powered by an electrical outlet, a fairly long power cord will be required. The larger the lawn, the longer the wire needed.

- A switch from a semi-automatic washing machine. To avoid having to invent anything special and spending money on electrical "guts" for the motor, it's better to take the motor and switch from a semi-automatic washing machine. Then all that's left to do is connect the motor from the washing machine and "the job is in the bag."

Besides the main parts, you'll also need a few fasteners: studs, bolts, nuts, washers—well, the usual stuff. Now let's talk a little about the necessary tools.

- Various open-end and socket wrenches.

- Electric welding.

- Drill.

- Measuring instruments.

- Multimeter.

- Bulgarian.

- Marker.

- Hammer.

- Pliers.

- Screwdrivers.

- Soldering iron.

Progress of work

Well, let's get to work. If, while building your own lawn mower, you realize some parts are missing or that you could use different ones instead, that's okay. After all, when you're making something yourself, you get caught up in the creative process and, without even realizing it, you're improving on the original design. The same will happen in your case. But let's not get too philosophical; let's get down to business.

Well, let's get to work. If, while building your own lawn mower, you realize some parts are missing or that you could use different ones instead, that's okay. After all, when you're making something yourself, you get caught up in the creative process and, without even realizing it, you're improving on the original design. The same will happen in your case. But let's not get too philosophical; let's get down to business.

The first thing we will do with our own hands is to make a cart chassis, to which we will need to attach wheels. The chassis should be located low to the ground, because we are making a lawn mower, not a cart for removing garden waste.

In the center of the platform, we cut a round hole large enough to accommodate the motor shaft, leaving some clearance. Place the motor shaft down so that it fits into the hole. Mark a location on the platform for the motor frame.

When the engine is mounted on the platform, it is easier to mark the location for its frame.

We assemble the corner pieces into a frame and weld them together. To ensure the engine sits securely in the frame, you can additionally attach it with a special clamp—there's no need to weld the engine housing to the frame. Next, we install the lawn mower handle. It can be welded, but it is better to secure it to the corners with bolts so that the lawn mower can be disassembled later if necessary.

Now we need to connect the motor. In this case, it's best to install the starting capacitor and other electrical components in a special plastic box. If you don't have one handy, you can use a regular plastic bottle. This bottle can be attached to the motor itself, but it's better to place the switch on the mower handle for added convenience.

Now we attach a suitable sleeve to the motor shaft, put a knife or cutting disc on it and secure it. In this case, it is important that the knife is positioned at the correct height and is securely fastened. To fit the blade onto the bushing, you may need to drill a hole in it—check for yourself. That's it, your electric lawn mower is ready. Now all you have to do is plug it in and mow your lawn for the first time.

Security measures

When using a homemade lawn mower, be careful. Do not turn on the device in the rain or when the grass has not yet dried. Factory-made lawn mowers have all electrical wires securely insulated, and the motor is encased in a waterproof housing. In our case, if we decide to mow the lawn in the rain or after, we can't avoid electric shock.

Do not give the lawn mower to children, and do not use it near children or pets. Before mowing, make sure the grass is clear of any foreign objects, such as children's toys, rocks, garden hoses, etc. If the blade jams while mowing, do not access it until the lawn mower is unplugged. Be sensible and everything will be fine!

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment