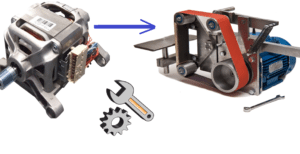

DIY Grinder from a Washing Machine Motor

The word "grinder" can be confusing to some, but there's nothing unusual about it. A grinder is a type of sanding machine designed for finer finishing of a workpiece. In this article, we'll show you how to make a homemade sanding machine using a washing machine motor. We hope you find this information helpful.

The word "grinder" can be confusing to some, but there's nothing unusual about it. A grinder is a type of sanding machine designed for finer finishing of a workpiece. In this article, we'll show you how to make a homemade sanding machine using a washing machine motor. We hope you find this information helpful.

Machine application areas

Before you begin assembling a machine using a washing machine motor, remember the safety precautions. The assembly and subsequent use of a homemade machine can be hazardous to your health. Be prudent and careful; if you are not confident in your skills, it is better not to undertake the construction of a homemade machine.

So, where is a grinder used, and why is it needed at all in the home? Most household tasks require sandpaper. By the way, DIY emery from a washing machine It's even easier to make than a grinder. If you're interested, check out the article with the same name on our website. Unlike sandpaper, a grinder is useful when you need to quickly and accurately sand a surface.

Please note! Grinder belts (75x457 mm) are available with any working surface, so you shouldn't have any problems in the future.

For example, if you're making handles for farming tools or slats for bee frames, you'll need to sand these parts down the line to avoid any problems later. You could do this by hand, but that would require a lot of effort and energy. A grinder makes the sanding process simple and straightforward.

We are making a mechanism

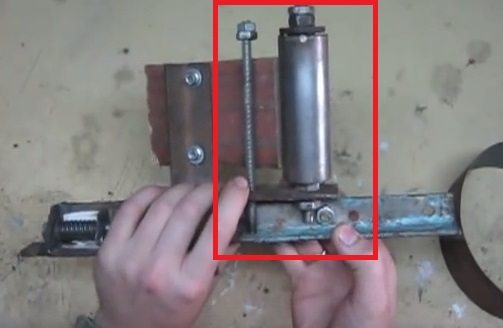

The most important element, besides the washing machine motor, is a homemade sliding unit, which is used to tension the belt and adjust its position. You can buy a ready-made moving mechanism for such a machine or have it manufactured by a professional, but then the cost of the finished product will approach that of a factory-made grinder, which is, of course, unacceptable. So, we'll try making this crucial part ourselves. Here are the materials you'll need:

- several pieces of 30 mm corner, one long – 40 cm and two short ones 15 and 25 cm;

- two long bolts and about ten nuts;

- hairpin;

- spring on bolt;

- metal strip 30x100 mm;

- short bolts, washers, nuts.

The roller parts had to be turned on a lathe. You can see them in the picture below: two bearings, a nut, the roller itself, and a unique shaft.

Accordingly, we'll need the following tools: a lathe, an angle grinder, a drill, an electric welder, wrenches, pliers, and a lot of patience. Here's what we'll do: weld the corners and plates together as shown in the picture below. Insert a bolt with a spring into the end of the structure. We'll need this bolt to adjust the belt tension.

! The main bolt will be held in place by two small plates with holes and threads that are welded to the bottom of the corner perpendicular to it.

Next, drill a hole in the top of the main corner, insert a short bolt, and screw in the short piece of corner. This piece should move slightly from side to side, and a roller with a bearing mechanism will be attached to it. The movement of this piece of corner will subsequently allow the tape to be adjusted.

We assemble the roller mechanism and bolt it to the bracket. Don't overtighten it so the roller rotates freely, but we also don't want the roller and bearings to slip off, so we tack-weld the bearings to the roller and tighten locknuts onto the ends of the shaft. Drill another hole under the roller in the bracket and secure a stud in it. Two nuts should be screwed onto one end of the stud, while the other end will rest against the main bracket. It is very important that the stud can be screwed in and out along the thread.

A short angle welded perpendicular to the main angle with a piece of chipboard screwed to it serves as a guide and, most importantly, protects the operator's hands when adjusting the belt. This is important for safety, as the homemade grinder is adjusted with a pin located dangerously close to the actively moving belt. Well, that's it, the mechanism is ready. Now you can connect the motor, slide the bushing onto its shaft, connect everything to the moving mechanism, and begin testing.

Engine and shaft

About that, How to connect a washing machine motor We've already talked about it quite a bit, so we won't repeat ourselves. Let's move straight to the next and final step of grinder assembly: connecting a motor from an old semi-automatic washing machine. We will protect the engine body with a sheet of thin sheet metal and fix it to a suitable frame.In our case, we welded the frame from angle iron, but you can mount the engine directly on the workbench.

! The capacitor that controls the engine start can be taken from the same semi-automatic washing machine.

As you can see, we used a motor with a long shaft, but if you have a regular washing machine motor with a short shaft, you'll have to invent something and increase its length. In the picture above, you can see that the motor shaft is fitted with a special wooden bushing, which we machined on a lathe. We'll attach the grinder belt to this bushing. The sliding mechanism we made earlier will be mounted just above the motor. The end result will be the machine you see in the picture below.

In conclusion, it's worth noting that making a grinder from a washing machine motor isn't easy, but if you're willing and have the itch, you can spend a couple of days crafting something similar to what's presented in this post. Just don't rush and remember safety precautions. Good luck!

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment