The washing machine is humming when it is turned off.

Sometimes, after hearing an incomprehensible noise, users are surprised to discover it's the humming of a switched-off washing machine. Objectively, a de-energized appliance can't make any noise, at least not its electrically powered components. So what's causing the hum?

Sometimes, after hearing an incomprehensible noise, users are surprised to discover it's the humming of a switched-off washing machine. Objectively, a de-energized appliance can't make any noise, at least not its electrically powered components. So what's causing the hum?

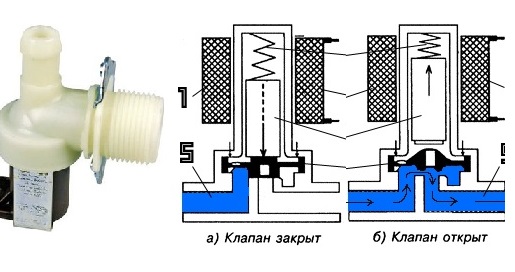

The washing machine's inlet solenoid valve may be making noise. What should you do in this situation, and how can you fix it? Let's look into the details.

We are convinced that the intake valve is to blame

When your washing machine hums while it's turned off, the first thing to check is the inlet valve. If it's open, water can still flow into the washer even when it's not powered. It's easy to confirm that this is the cause of the noise.

Turn off the water supply to the machine using the shut-off valve installed in front of the washing machine's inlet hose.

If a shut-off valve isn't provided, turn off the cold water supply at the entrance to the apartment. This will remove pressure from the system, preventing water from reaching the machine, and the humming sound. If the noise actually stops, then the problem is definitely with the solenoid valve.

You should also listen for any other unusual noises, such as the sound of water draining. With the inlet valve open, the machine's tank will gradually fill, and any excess will drain into the drain by gravity.

We remove the valve and get ready to check it.

How do I diagnose a solenoid valve? First, unplug the washing machine and move it to the center of the room to allow easy access to all sides of the machine. Next, drain any remaining water from the system. To do this, you'll need to remove the waste filter—it's located in the lower corner of the machine, behind a false panel or access hatch.

Before removing the filter, place a basin under the machine to collect the water. Then, you can remove the dust collector from the housing. The remaining liquid from the system will drain into the prepared container. Then, clean the plastic coil and replace it.

The inlet valve is located under the top cover of the washing machine. To remove the panel, you need to unscrew the two screws holding it in place. Then you'll need to remove the element itself. You'll need the following tools:

- a pair of screwdrivers (Phillips and slotted);

- pliers;

- pliers with pointed tips;

- multimeter.

Removing the water inlet valve from the machine is easy. Simply disconnect the power supply wires and hoses (after loosening the clamps), and unscrew the retaining bolts. After that, the part can be removed from the washing machine.

What breaks in the intake valve?

A solenoid valve can stop functioning properly for a variety of reasons. Diagnostics will determine the exact cause of the malfunction. We'll cover the most common issues.

- Clogged filter element. Immediately after the inlet hose, before the inlet valve, there's a filter element designed to trap impurities found in tap water. The filter becomes clogged, reducing the flow of liquid. Cleaning the filter element is sufficient to solve the problem.

- Dirt buildup on the valve membrane. The elastic seal should move freely up and down as water is drawn into the machine. When it becomes coated with dirt, it loses its tight seal, causing the valve to malfunction. To see the seal, you'll need to disassemble the intake manifold. If cracks are present, the seal will need to be replaced; cleaning off any buildup or rust is sufficient.

- Spring problems. Over time, the valve mechanism may malfunction—the stem will stop moving up and down. A broken or deformed spring will need to be replaced.

- Cracks in the valve body. The device's "packaging" is plastic, so it's easily damaged. If there are cracks in the "casing," water will leak into the washing machine, affecting other components. This can cause the machine to generate an electric shock, which can lead to a short circuit. To resolve the issue, the inlet element will need to be replaced.

The solenoid valve housing often cracks in washing machines installed in unheated rooms. At sub-zero temperatures, the inlet freezes, expands, and pushes the device's casing apart. Furthermore, the rubber membrane loses its properties after this "freezing." Therefore, if your washing machine starts leaking after spending the winter at your dacha, replace the inlet valve.

After removing the inlet device from the washing machine body, inspect it carefully. If the magnetic coils are deformed, the water supply valve will have to be replaced; in this case, it cannot be repaired. We'll tell you how to diagnose a part.

Is the valve coil intact?

The solenoid valve's performance depends primarily on the condition of the coil. It is the coil that activates the piston rod, allowing water to flow into the washing machine. There are two ways to test it.

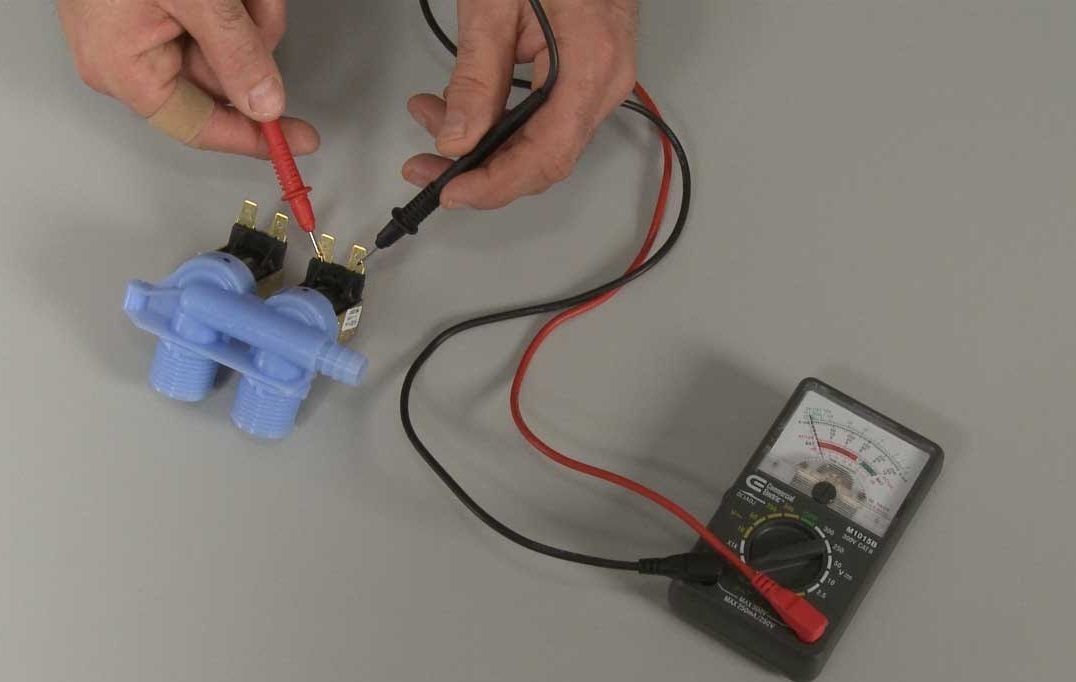

The easiest way to test a magnetic coil is with a multimeter. Set the device to resistance mode. Then, apply the tester's probes to the coil's contacts.

If the intake valve is working properly, the multimeter will display a resistance reading in the range of 2000-4000 Ohms.

Automatic washing machine solenoid valves can also be double or triple. In this case, each coil is individually tested with a multimeter. The resistance should be within the normal range.

Another, more complex method involves applying 220 volts to the coil. This voltage should create a magnetic field and pull the rod upward (you'll hear a distinctive click). When the power is turned off, the part will snap back into place. Testing the device this way should be done with extreme caution. Experts still recommend using a multimeter.

Let's try to fix the valve.

The intake manifold can usually be repaired. The valve is fairly easy to disassemble—even a novice can handle it. In a worst-case scenario, even if the repair fails, the entire part can be replaced—it's inexpensive.

To disassemble the water supply valve, you need to:

- pry up the coil with a thin screwdriver and remove it;

- Use pliers to remove the rods. If the pieces are stubborn, treat them with WD-40 and try again in 15 minutes;

- pull out the metal rod with the elastic membrane and spring.

What to do next? After disassembling the valve, inspect each of its components for damage. If the parts are simply dirty, clean them and put them back.

If you notice that the spring, membrane, or other part of the intake manifold is deformed, replace them with new ones. You can order similar parts online or look for them at specialty stores in your city.

If the damage is beyond repair, a new solenoid valve will need to be installed. This may occur, for example, if the coil fails. The cost of an inlet valve typically ranges from $10 to $25, depending on the washing machine model.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment