Characteristics of the Malutka washing machine motor

Looking at the compact and simple design of the Malutka washing machine, it's hard to believe that it houses a very powerful motor. The manufacturer managed to equip it with a fairly large motor, even housing it in a separate housing. But its large size isn't its only distinguishing feature. This motor is also known for its exceptional reliability, capable of providing years of trouble-free service. Let's take a closer look at the Malutka washing machine's motor specifications and evaluate its advantages and potential.

Looking at the compact and simple design of the Malutka washing machine, it's hard to believe that it houses a very powerful motor. The manufacturer managed to equip it with a fairly large motor, even housing it in a separate housing. But its large size isn't its only distinguishing feature. This motor is also known for its exceptional reliability, capable of providing years of trouble-free service. Let's take a closer look at the Malutka washing machine's motor specifications and evaluate its advantages and potential.

Engine specifications

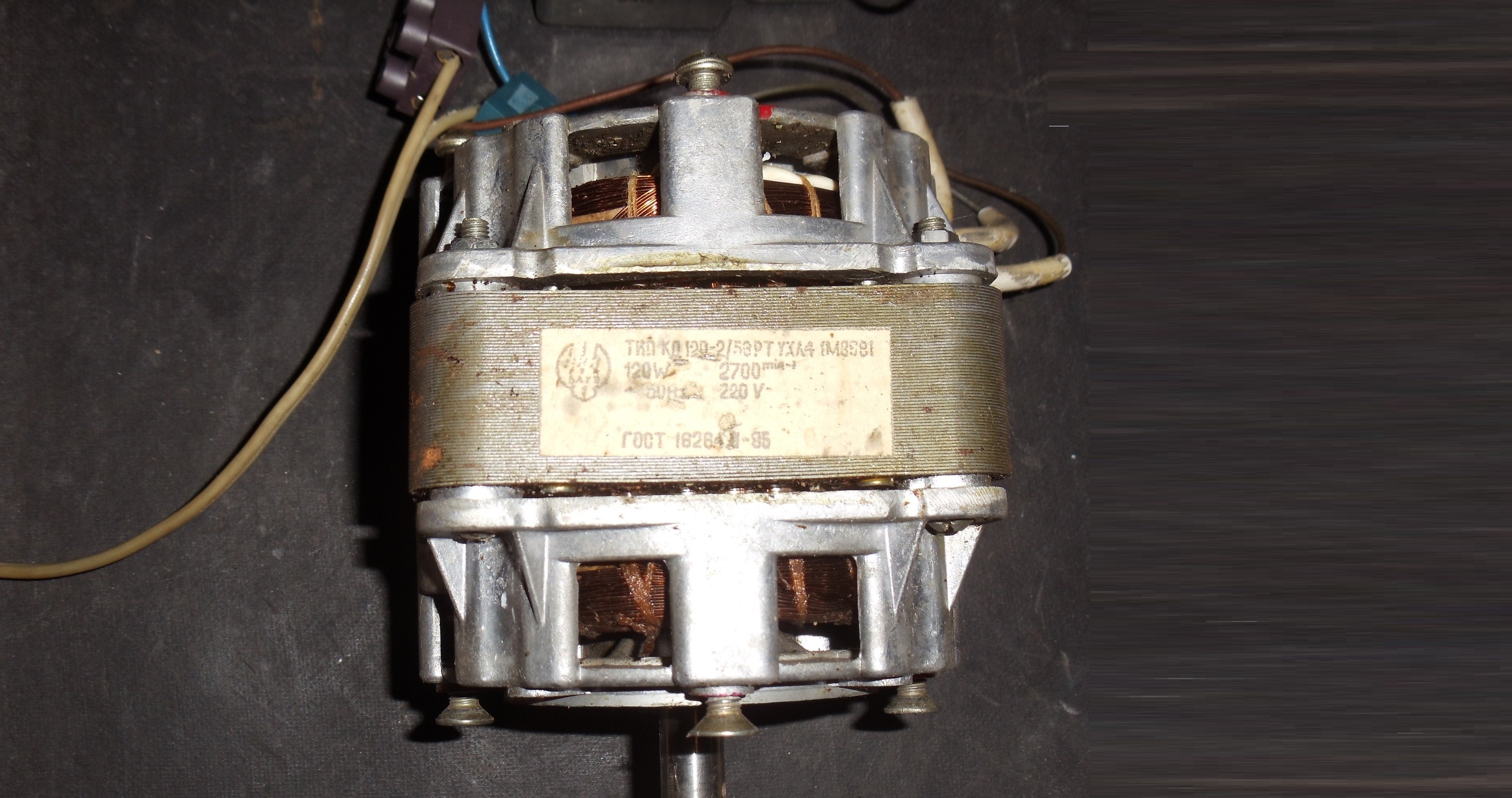

The vast majority of Malutka washing machines were equipped with KD 120 electric motors. This is a single-phase, two-pole capacitor induction motor with a rated power of 120W. This device is ideal for driving actuators in household washing machines and centrifuges.

The main technical characteristics of KD 120 are as follows:

- input and output supply voltage – 220V and 115V;

- current frequency – 50-60 Hz;

- rotation frequency – 2650-3270 rpm;

- current consumption – from 1.2A;

- rated torque – 0.43 Nm;

- no-load losses – no more than 200 W;

- short circuit losses – no more than 700 W;

- shaft diameter – 14 mm;

- efficiency factor – 40-45%;

- sound level – 48 dB;

- weight – 4.8 kg.

The KD 120 electric motors in Malutka washing machines accelerate to a maximum of 2650-3270 rpm.

An important indicator is the maximum torque to nominal torque ratio, which is 2.67 for the KD 120. The minimum torque ratio is 1.54. One motor cycle lasts 6 minutes. Of these, 15 seconds are spent short-circuiting, 3 minutes 45 seconds operating at nominal load, and 2 minutes paused. The shaft rotates clockwise.

As for safety, the KD 120 engines:

- have a protection rating of IP10;

- cooled using method 1C01;

- manufactured with insulation of heat resistance class B;

- have a maximum permissible excess of windings of 75-80 degrees;

- are protected from overheating by the presence of an electrothermal relay.

The average service life of such motors is up to 15 years. The manufacturer provides a 2.5-year warranty from the date of retail sale. It's important to understand that motors must be protected from accidental contact with the contacts and moisture ingress. Otherwise, a short circuit will occur, resulting in burnout of the winding or permanent damage to the mechanism.

How to use an old engine?

The electric motor in the KD 120 washing machine is considered extremely reliable. With an average service life of 10-15 years, it often outlives the machine itself. There's no need to throw away a working motor along with the washing machine—it's better to make something useful out of it. For example, a mobile sharpening machine.

First, you need to make sure the old motor is working properly. First, disconnect the motor housing from the washing machine's main tank and place it on a flat, dry surface. Next, use a screwdriver to remove the bolts from the mounting disc and free the motor from its plastic housing. Then, connect it to the power source and start the machine. If the motor starts working, we can begin making the sharpener.

To make a sharpener from the motor of a Malutka washing machine, you will also need a sheet of metal, plywood, screws, a power cord, and an abrasive disc.

The instructions are as follows:

- screw wooden blocks to the bottom of the original motor housing (to secure the device to the table);

- connect the power cord with a plug to the motor;

- insert the motor into the housing;

- cut a circle from sheet metal and sand the edge;

- secure the disk with a 20 mm nut;

- use a drill to drill 8 holes around the perimeter of the disk;

- cut a circle out of 12 mm thick plywood, 2-3 cm larger than the metal disk;

- place the disk with the nut on the plywood circle and align them in the center;

- screw the screws into the drilled holes;

- fix the resulting base for the sharpener on the electric motor;

- glue an abrasive disc of suitable grain size to the plywood;

- start the grinder.

You can go further and improve the design: replace the old plastic housing with a new one or paint it with colored paint. The main thing is to change the abrasive discs regularly and follow safety precautions when using the device.

Interesting:

3 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

What is the diameter of the shaft near the impeller?

Shaft diameter 12mm, standard thread - 8mm.

12 mm