Where can I use a motor from an automatic washing machine?

After buying a new washing machine, don't rush to get rid of your faithful "home helper." It's better to reuse the motor from an automatic washing machine. Using an electric motor as a basis, it's easy to construct various useful devices. We'll tell you about some DIY projects that have already been assembled by DIYers.

After buying a new washing machine, don't rush to get rid of your faithful "home helper." It's better to reuse the motor from an automatic washing machine. Using an electric motor as a basis, it's easy to construct various useful devices. We'll tell you about some DIY projects that have already been assembled by DIYers.

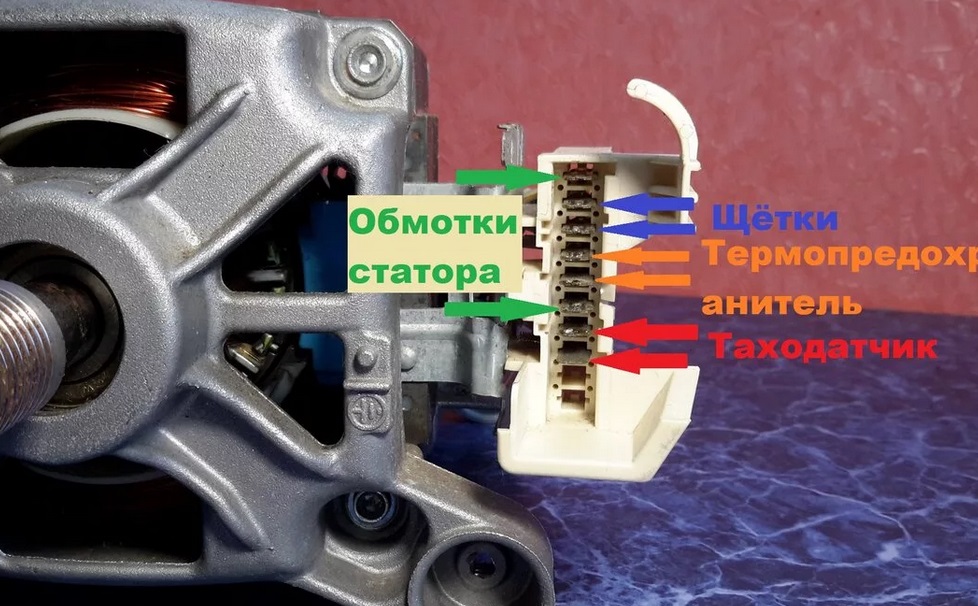

Let's start the engine first.

Before using the engine again, you should make sure that it is working properly. It is important to start the engine and see if it has lost power and is able to maintain revs under load. To do this, you'll need to connect the motor to an AC power source. The procedure is as follows:

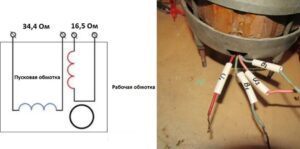

- Prepare a multimeter - this is a special device needed to identify the paired wires of the motor winding;

- Connect the multimeter probe to a random wire and find its pair (the tester will indicate the correct connection). The remaining two wires will also be considered paired;

- measure the resistance of each winding (the one with the higher resistance and smaller cross-section is the starting one);

- connect the wires from the different engine windings and connect them to the electrical network;

- observe the engine operation;

- Change the direction of the electric motor's movement in the opposite direction by swapping the contacts of the starting winding.

When diagnosing an engine, it's important to follow safety precautions. If the component passes the test, it's approved for use in your DIY project.

An electric motor can be used to make a lathe, an apple or feed crusher, a grass cutter, a concrete mixer, or an emery machine.

There are many options, but your task is to choose a product that will truly be useful around the house. We'll tell you how to build such devices yourself.

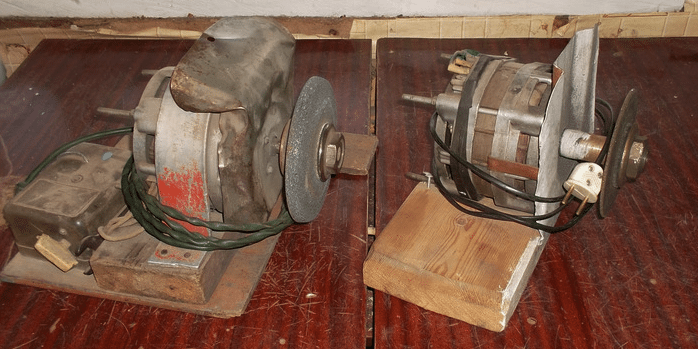

Universal lathe

You can use a washing machine motor to build a metal lathe. In fact, making such a machine is very simple. All you need to do is attach an adapter to the motor shaft from an automatic washing machine.

We recommend not permanently attaching the adapter. It's preferable to leave the attachment removable. This will make the machine more versatile—it can be used not only for turning objects, but also for sharpening knives, garden tools, cutting pipes, and more.

Various attachments can be attached to the base of the electric motor shaft: a grinding wheel, a cutting wheel, and others.

There's also no need to nail the homemade device to a fixed base. A portable design is more convenient. A thick wooden board will do as a base. To secure the machine, you can use brackets that are screwed to the wood with machine bolts. To start the homemade device, use a standard switch or a washing machine cord.

Feed crusher

This homemade device is useful for preparing feed for cows, horses, pigs, and other livestock. If you find a powerful enough motor, you can build a forage cutter, apple crusher, grass cutter, or grain crusher. Moreover, these homemade devices are in no way inferior to store-bought ones.

To build such a device, the motor from an activator washing machine would be too weak. However, a washing machine motor would be suitable; it has just the right amount of power. To make a food grinder, you'll need three main components:

- automatic car engine;

- a metal container (ideally, the body of a vertical-loading activator machine – it’s easy to find at any metal collection point for pennies);

- metal blades (they will grind the food).

The blades that act as knives should be slightly smaller than the metal body. They should rotate freely within it, but not reach the edges.

The algorithm of actions for designing a feed crusher will be as follows:

- prepare the necessary components;

- cut a hole in the bottom of the housing to remove the crushed food;

- Fix the first cutting blade at the bottom of the tank, and the second one 45-50 cm higher. To improve the degree of grinding, it is advisable to use two different shafts so that they rotate in opposite directions;

- secure the washing machine motor on top and connect it to the shafts;

- make a hole in the top panel where the grain will be poured;

- Connect the power cord to the motor.

After that, you can test your homemade device. This machine will grind grain just as well as a store-bought model. And it will cost many times less than a factory-made equivalent.

Sanding machine

A sanding machine is a useful tool for any home. It's incredibly simple to make. All you need is a washing machine motor and a sharpening stone.

Sometimes the stone's bore isn't the right size for the engine shaft. In this case, you'll need to make an additional adapter—it needs to be specially ordered. Any lathe operator can make a part of the appropriate diameter.

In addition to the adapter, you'll need a nut, screw, and washer. The motor's rotation directly depends on the thread type on the coupling. For the motor to rotate left to right, a left-hand thread is required; for the reverse direction, a right-hand thread is required.

If necessary, the movement of the electric motor can be adjusted by swapping the winding wires.

Next, attach the sharpening stone to the motor shaft and connect the motor's operating winding to a 220-volt power source. Two starting cables are connected to the coil.

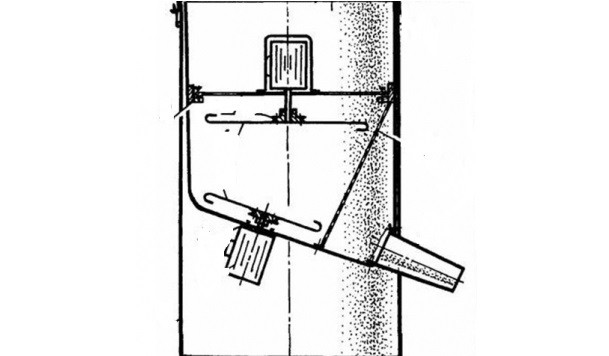

Concrete mixer

A homemade concrete mixer is useful if construction work is imminent. Manually mixing large quantities of concrete is quite difficult, and renting one is prohibitively expensive. In this case, you can build the machine yourself.

First, you need to create a solid foundation to which the concrete mixer will be attached. Wooden beams measuring 15x15 cm are suitable for this base. To secure them together, use screws and metal channels.

The engine shaft and the main tank shaft should be aligned. Based on this, a shelf should be made on the frame to hold the motor. Next, you can begin installing the gearbox.

The engine and gearbox pulleys must be positioned in the same plane. Failure to do so will overload the motor and eventually burn out. You can use a washing machine tank as a container for mixing concrete. Next, place the shaft in the container, and attach the blades to it (they will mix the sand, cement, and water). It's important to ensure the blades are positioned symmetrically. Then, attach the drive belts to the pulleys.

To prevent concrete from getting on the motor, it's best to hide it under a protective cover. Once you've completed the project, connect the power cables. For convenience, consider adding "Start" and "Off" buttons.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment