How to change a bearing in a washing machine

How do you know if a washing machine bearing needs replacing? It makes noise, creaks, and knocks while washing. These unpleasant sounds can worsen over time. If you don't replace the defective part promptly, it will be more difficult to do later. Furthermore, the knocking noise can eventually develop into an unbearable roar. If you don't replace this part at all, the machine will soon fail completely. Repairs will be extremely expensive. The best option is to replace the bearing immediately upon discovering a defective one.

How do you know if a washing machine bearing needs replacing? It makes noise, creaks, and knocks while washing. These unpleasant sounds can worsen over time. If you don't replace the defective part promptly, it will be more difficult to do later. Furthermore, the knocking noise can eventually develop into an unbearable roar. If you don't replace this part at all, the machine will soon fail completely. Repairs will be extremely expensive. The best option is to replace the bearing immediately upon discovering a defective one.

Bearings can fail after prolonged use of a washing machine. They also break due to water ingress. Water leakage causes corrosion, which damages the part. Leaks are caused by the seal. It has a limited lifespan and often begins to leak after 5-7 years of use. The seal is located near the bearings, and it is usually replaced every time the bearings are replaced.

Replacing a bearing yourself is a very complex and time-consuming task. Therefore, before attempting it, you need to decide whether you're ready to handle all the necessary work yourself. If the task is too complex, it's best to call a professional technician. The entire labor, including the replacement part, will cost you approximately a third of the price of a new washing machine. Of course, prices in the home appliance and repair market can vary, so the prices listed here are approximate.

If you've decided to do the job yourself, this article will help. And for those who prefer videos, we recommend scrolling down to find the entire repair process in video format.

Necessary tools and parts

For this task, we'll need to practically completely disassemble the washing machine. And naturally, we'll need tools. What exactly do we need?

- Pliers.

- Screwdrivers (slotted and Phillips).

- A special screwdriver with various attachments.

- Round-nose pliers.

- A set of keys of different sizes.

- Waterproof sealant.

- Chisel (blunt).

- Rubber mallet.

- A large, ordinary hammer.

We'll also need a seal and bearings. These can be purchased at various service centers and specialty stores. If you don't know of any, simply type "Buy washing machine bearings" into Yandex, Google, or another search engine. It's best to add your city's name to this query. For example, "buy bearings in Moscow." The search results will show you companies that sell parts. Tell them the make of your washing machine. They'll then inform you of the cost of spare parts. As a last resort, you can remove the old parts first and then select identical new ones.

We'll also need a seal and bearings. These can be purchased at various service centers and specialty stores. If you don't know of any, simply type "Buy washing machine bearings" into Yandex, Google, or another search engine. It's best to add your city's name to this query. For example, "buy bearings in Moscow." The search results will show you companies that sell parts. Tell them the make of your washing machine. They'll then inform you of the cost of spare parts. As a last resort, you can remove the old parts first and then select identical new ones.

Disassembling a washing machine

First, we need to remove the top part of the case (cover). It's secured with two screws on the back. Once they're removed, slide the cover toward the back of the case. Remove it. Then, completely remove the dispenser from the machine. On some models, you need to press the latch to release the dispenser. Next, remove the control panel. To do this, unscrew the screws holding it in place. The panel can be carefully laid on the side of the case.

First, we need to remove the top part of the case (cover). It's secured with two screws on the back. Once they're removed, slide the cover toward the back of the case. Remove it. Then, completely remove the dispenser from the machine. On some models, you need to press the latch to release the dispenser. Next, remove the control panel. To do this, unscrew the screws holding it in place. The panel can be carefully laid on the side of the case.

Next, open the hatch and remove the outer clamp of the cuff. Clamps come in different types. Some can be removed with round-nose pliers. Others can be removed with a flat-head screwdriver. Once the clamp is removed, we need to separate the cuff from the front of the housing and tuck it inside the machine. This will keep it out of the way.

Next, open the hatch and remove the outer clamp of the cuff. Clamps come in different types. Some can be removed with round-nose pliers. Others can be removed with a flat-head screwdriver. Once the clamp is removed, we need to separate the cuff from the front of the housing and tuck it inside the machine. This will keep it out of the way.

Then we unscrew the lock. It's held in place by two screws. We unscrew them and insert our hand inside between the cuff and the wall.  We separate the locking device from the inside of the car. Remove all remaining fastenings and remove the front part of the housing. We'll also remove the rear part of the housing first, to avoid unnecessary fussing later.

We separate the locking device from the inside of the car. Remove all remaining fastenings and remove the front part of the housing. We'll also remove the rear part of the housing first, to avoid unnecessary fussing later.

Next, we disconnect the dispenser hopper from the machine's tank. To do this, we'll need to remove anything in the way and loosen the clamp. Put everything away where it won't get in the way. Next, we need to remove the counterweight (if it's in the front). If it's in the back, we'll access that too and be sure to remove it. The counterweight is usually secured with bolts. We'll unscrew these bolts with a screwdriver.

Next, we move to the heating element. On most models, it's located at the back. On some, it's at the front. Before removing it, take a photo of the wires so we can reconnect everything in the correct order. Then, remove the heating element's fasteners. Most often, it's held in place by a single nut. Loosen the nut and push in the screw. Then, using a flat object (such as a screwdriver), pry it up and remove the heating element.

Next, we move to the heating element. On most models, it's located at the back. On some, it's at the front. Before removing it, take a photo of the wires so we can reconnect everything in the correct order. Then, remove the heating element's fasteners. Most often, it's held in place by a single nut. Loosen the nut and push in the screw. Then, using a flat object (such as a screwdriver), pry it up and remove the heating element.

Next, we remove the hose that attaches to the tank. We've already learned how to disconnect the clamps, so this is easy. Then we remove any wires that may be attached to the tank.

We approach the machine from behind and remove the drive belt. Next, we disconnect the wires leading to the machine's motor. Then we remove the screws that secure the motor. Then we remove the motor by pulling it toward us.

We approach the machine from behind and remove the drive belt. Next, we disconnect the wires leading to the machine's motor. Then we remove the screws that secure the motor. Then we remove the motor by pulling it toward us.

Next, we unscrew the screws that secure the shock absorbers. And separate their lower sections from the car's wall. All that's left is to remove the springs. The tank can then be removed. All this must be done carefully to avoid dropping the tank.

We disassemble the tank and change the bearings

Now we can place the removed tank on the table. It will be more convenient to continue disassembling it there. The rubber used to make the seal may deteriorate during further work, so it's best to remove it. But first, it's worth marking its position with one or more marker lines. Next, remove the remaining clamp and pull out the seal.

Now we can place the removed tank on the table. It will be more convenient to continue disassembling it there. The rubber used to make the seal may deteriorate during further work, so it's best to remove it. But first, it's worth marking its position with one or more marker lines. Next, remove the remaining clamp and pull out the seal.

Position the tank so that it's easy to remove the pulley. The pulley is held in place by a single bolt. Unscrew it. Once the pulley is removed, push the shaft into the tank. Try doing this by hand. If that doesn't work, a rubber mallet will do the trick. Then disassemble the tank into two halves. They are usually held in place with latches and/or screws.

Once we've separated the tub and removed the drum, we need to inspect the spider, shaft, and bushings. If the machine has been running for a long time with broken bearings, there's a chance these parts may have become permanently damaged.

Once we've separated the tub and removed the drum, we need to inspect the spider, shaft, and bushings. If the machine has been running for a long time with broken bearings, there's a chance these parts may have become permanently damaged.

For example, a crack might appear in the universal joint. The shaft might deteriorate so much that a new seal won't hold back water. The shaft might develop play, and in this condition, it won't last long. If any of these defects are noticeable, repairs will require additional investment.

But let's hope you didn't delay starting the repair and your machine is more or less in good condition. We'll clean the bushing and shaft of any scale or other dirt that may have accumulated there. This process must be done very carefully to ensure no residue remains and to ensure a completely smooth finish.

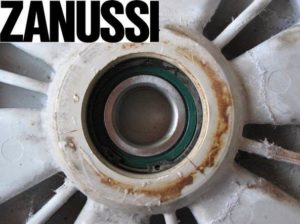

After that, we'll remove the bearings. For this, we'll need a hammer and a blunt chisel. Take the part of the tank where the bearings are located and knock them out using these tools. Knock them out carefully to avoid damaging the tank. One mechanic I know did this on his knees. This prevented the tank from breaking from underneath due to too much force.

After that, we'll remove the bearings. For this, we'll need a hammer and a blunt chisel. Take the part of the tank where the bearings are located and knock them out using these tools. Knock them out carefully to avoid damaging the tank. One mechanic I know did this on his knees. This prevented the tank from breaking from underneath due to too much force.

The oil seal usually falls out with the bearing. If it doesn't, remove it. Carefully clean the bearing mounting areas on the tank, removing any dirt or other debris. Next, treat them with Litol-24 lubricant.

Next, we install the new bearings, hammering them in with the same hammer and chisel. Don't forget to install and generously lubricate the oil seal with Letol-24. Next, we assemble the tank. The tank seam and gasket should be sealed with a waterproof sealant.

Now all that's left to do is reassemble the entire machine. After assembly, we'll perform a test wash to ensure the new bearings are working properly.

By the way, taking photos with your phone or camera during disassembly can make reassembly easier. Be sure to photograph all the parts you think will be difficult to reassemble.

Interesting:

35 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

I put off getting the bearing repaired; the car had been operating in those conditions for a long time. Finally, a mechanic came, disassembled the car, took the drum, and took it back to his shop, saying he'd strained his back lugging all the tools. Now he's calling and saying the bushing is worn out (2/3 worn out), and he doesn't do that kind of work. No one in our city replaces bushings anymore; it's a mechanic's job, etc., etc. There's no reason not to believe him, since we've been driving the car for about six months with a bearing that was making a terrible noise.

The question is: does it make sense to repair the bushing or buy a new unit right away?

If you have a good turner, it makes sense to repair it.

Alternatively, you can buy the part of the tank where the bushing is located - new or used.

Or you could find a lathe worker and bore the bushing in the tank, then insert a liner that will match the internal diameters of the original bushing. It all comes down to money: if you're in a small town and wages are low, buying a new machine will cost about 20 tons, while fixing the old one will take a couple of weeks of fuss, but you'll only have to pay the lathe worker a ton and that's it.

Well done, it's just a shame that the fuel tanks in modern cars need to be cut.

Our washing machine has never broken, and it's been working perfectly for 10 years now, which is surprising. We do try to take good care of it, though: we clean and dry it, and add Calgon to the wash cycle.

We also wash with Calgon to soften the water, but it negatively impacts the machine's performance. Although there are many other factors to consider to keep the machine running smoothly.

Calgon is a scam, I've never used it, I took the machine apart, everything inside is fine (except the bearings).

We have the same story. We never use Calgon. We use citric acid very rarely, once or twice a year, and even then, as a preventative measure. But the bearings are finished…

Citric acid is good, but replacing the universal joint is even better. It's made of aluminum alloy, which is easily broken down by citric acid.

How much does it cost to replace drum bearings?

In Vladivostok, starting at 5,500 rubles with bearings and seals, and if you're replacing them yourself, you can buy the cheapest imported bearings and seals. Why the cheapest bearings? Because if the seal leaks, any bearing is doomed!

Is the price the same for both a collapsible and a non-collapsible tank?

No one will officially replace bearings in a non-disassemblable vehicle. Only private mechanics, not service centers, will undertake this. And only without a warranty.

Two bearings, 6205 and 6206, cost me $5.50, plus a $2.80 oil seal. LG F1022ndr washing machine, direct drive.

Is the seal some kind of special one?

When buying a washing machine, you should carefully consider not only the company's warranty and reviews (as some of them are paid for and not always accurate), but also its repairability, just in case. Avoid buying a machine with a non-detachable tank (as you'll have to replace the entire tank or upgrade the machine). Avoid LG and Westel machines, as the bearing seal on the axle has a coating that wears off when using non-Calgon powder. This leads to corrosion and subsequent scuffing of the seal, which then allows water to seep into the bearings and ruin the machine. The only solution is to replace either the tank or the tank crosspiece (regardless of the machine model).

It's worth choosing machines for which parts are readily available and which are compatible with other models from the same manufacturer. It's also worth choosing machines with a non-coated drum shaft; these machines last a long time and have no problems with bearings or drums.

What kind of experts are spouting nonsense about LG washing machines? I've been using this brand for 12 years without Calgon, and I've had absolutely no problems. The drums in LGs are removable, the crosspieces are bolted on and easy to replace... Just install genuine Korean bearings, original seals, and crosspieces, and your "skis" will last another 20 years!

What are you babbling about? I have an LG wd80150s. It's been around for 14 years. Everyone I know has had two different machines. And mine, for the first time in 14 years, has a bearing that's making noise. I'm hoping I can get away with just replacing it. Before you throw anything at the fan, think about it—people are reading your story.

Can you tell me if the Candy CSBL 75 washing machine has a detachable tank?

Hello. I learned a lot of useful information.

Zanussi TA833v washing machine, it looks like the bearing is failing.

Is it worth the trouble? And what machine, or more precisely, brand, do you recommend?

Good afternoon. Which model would you recommend?

We have a 13 year old Zanusi and it seems the bearing is failing. Should it be repaired or what?

Zanussi 16 years - the bearing failed (the drum was moving up and down and making a humming sound) I had to take the whole machine to a repairman - I decided to disassemble it myself and ended up changing only the bearings and the oil seal, everything else is fine - so I think it's worth changing the bearings and just checking everything else - the cuff on the door (if it's torn 4,500 rubles, if the shaft is worn out or the seat in the housing - also about that) I initially counted on 14 thousand. But for now it costs 1.5 thousand rubles - 300 x 2 - bearings 280 rubles - oil seal and about 500 rubles - oil seal grease (30 g) you can do it cheaper yourself, and then there's the labor 3-3.5 thousand rubles.

My Candy has had a noisy engine bearing for 15 years. Can I still drive the car, as the mechanic said he can't replace the bearings? Please advise.

Good afternoon! Thank you very much to the author of this article! Thanks to you and people like you who share information online, I replaced it myself; the repair cost $8. Technicians charge $35 per minute.

Bearing 6205 and 6206 + oil seal.

Thanks again for the article!!!

My washing machine's drum stopped spinning during the spin cycle. Could there be a problem with the bearings?

I need the dimensions of the seals and bearings for an Indesit iwsc5085 washing machine.

What bearings does the Atlant SMA 50C102 have?

My new Siemens machine lasted less than a year. The drum started humming during the spin cycle. I took it apart. A large bearing was rusty. Water had leaked through the seal—that's the quality of modern machines.

My washing machine is making noise. I bought new bearings, but I can't get the drum out to install them. What should I do?

My advice to you: if you're considering replacing the bearings in your washing machine yourself and haven't used hand tools much before, don't do it. It's better to find a qualified professional.

After purchasing household appliances, I disassemble and lubricate the bearings before plugging them in. And I've never had a single instance of the bearings being lubricated. Sometimes, a greased separator is barely noticeable.

I've had my Indesit for 4.5 years. Now it's making a noise. It practically howls when spinning at high speed. The drum must be spinning hard. What is it? Bearings? How many do I need? Two? And a seal?

LG, 18 years old. The bearing started making noise. I decided to fix it myself. The tank is collapsible and was hard to knock out. I placed it on two stools and knocked it out with a hammer through a piece of wood. Then another problem occurred: the bearing wouldn't come off the shaft.

I treated it with WD and off I went. Two auto repair shops removed this bearing. Thanks for the free service. The problem is, the seal is a total wreck—replacing it is understandable, but the shaft underneath is a complete disaster. The universal joint needs replacing for 3,500.

I didn't have time to look. I spent about 2 hours sanding and took off 0.8 mm. I polished it (a C grade). The new standard oil seal fit, and I assembled it. It started working (by the way, the heating element was punctured. We washed it with cold water and it seems to be fine). I think the oil seal will last for about 2 years. Then I'll have to replace the universal joint. It all sounds good now. But it was a real waste of time and about 12 hours of wasted time.

You read and gasp.

The good old Oka has been running for 50 years already!

Work clothes and more delicate underwear are all perfectly fine! And there are no hassles whatsoever. We've had to replace two leather belts in the entire process, until we got the VAZ2108 belt… It's been in good shape for 25 years now.