How does an LG washing machine work?

Technology is becoming increasingly complex every day, and it's being incorporated into new washing machines. However, this doesn't mean you shouldn't even try to understand this appliance. Knowing how an LG washing machine works can be very useful not only for general education but also for potential home repairs. In today's article, we'll take a detailed look at the structure of an automatic washing machine and discover the functions of its various components.

Technology is becoming increasingly complex every day, and it's being incorporated into new washing machines. However, this doesn't mean you shouldn't even try to understand this appliance. Knowing how an LG washing machine works can be very useful not only for general education but also for potential home repairs. In today's article, we'll take a detailed look at the structure of an automatic washing machine and discover the functions of its various components.

The operating principle of this machine

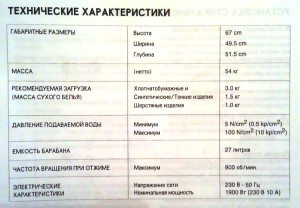

Any work cycle begins with loading dirty items into the drum. In this process, it is important to consider the drum capacity, which can accommodate both a large amount of laundry, for example, as much as 10.5 kilograms in the LG AI DD TW4V3RS6W machine, and a small one, say, 2.5 kilograms in the LG TW252S washing machine. Immediately after loading the detergent dispenser, add the detergent or gel. The final step is selecting the operating mode and additional features, after which the cycle is started using the "Start" button. Now let's learn how a washing machine works.

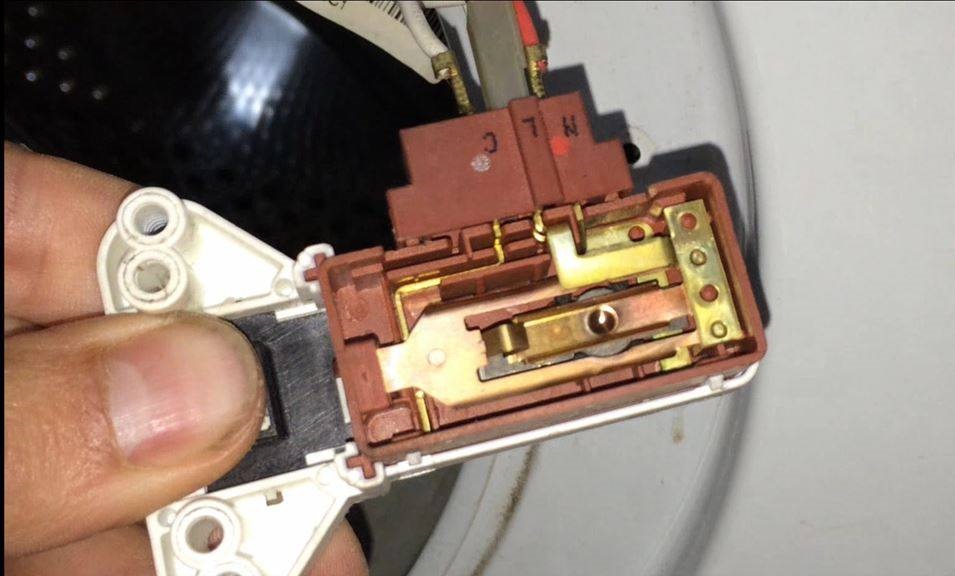

- Immediately after starting the washing machine, the control module supplies power to the door locking device to securely lock the door, which occurs within the first few seconds of activating the cycle. This prevents the door from opening accidentally during the wash cycle, preventing water from leaking.

- Afterwards, the drain pump is activated, which begins pumping out the remaining water from the tank so that the water used in the previous cycle does not get on your clothes.

There may not be any dirty waste water in the tank at all, but the pump will still work just in case.

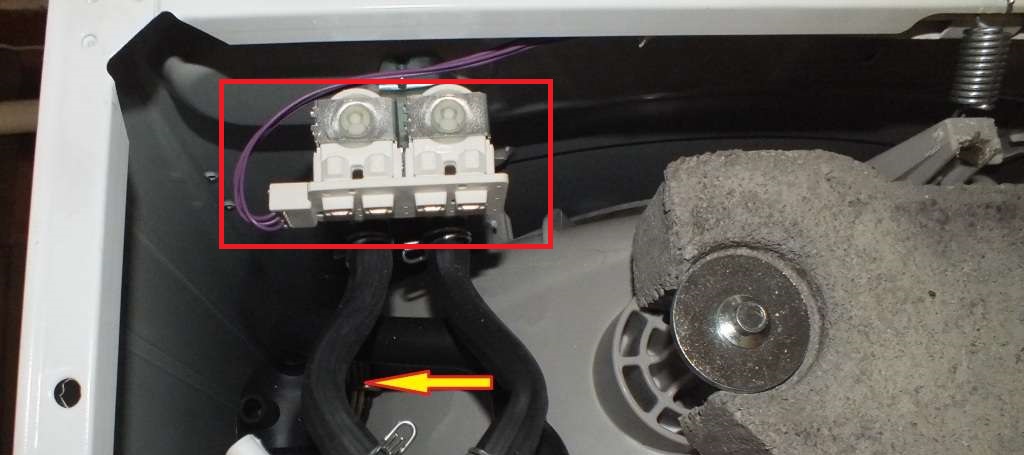

- The control module will then send a command to open the inlet valve, causing water to begin flowing into the washing machine.

- The liquid will pass through the detergent dispenser into the drum, washing away household chemicals into the tank, so that the active detergent for washing clothes will also get there along with the water.

- At the same time, while the liquid is being collected, the drum will begin to rotate slowly so that the clothes inside are evenly wetted.

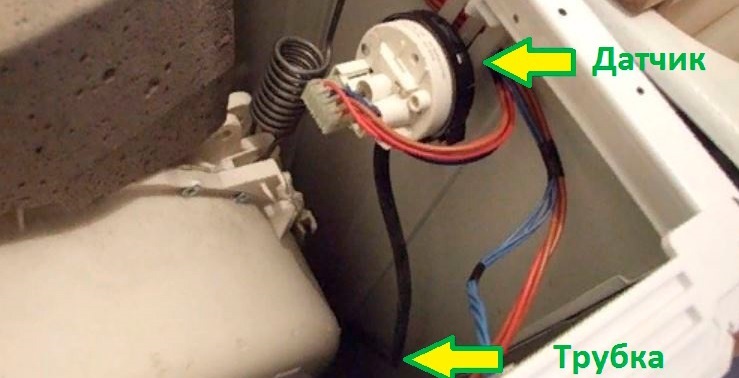

- The liquid will continue to be collected until the water level sensor determines that there is enough water in the tank for operation.

- After this, the pressure switch will send information about a sufficient water level to the control module, so that it will give the command to close the inlet valve.

- The module will now make the motor work fully so that it activates the rotation of the drum according to the program selected by the user.

Since the programs always pursue strictly specific goals, the reel will always spin in an intricate manner - alternating between sides and rotation speed.

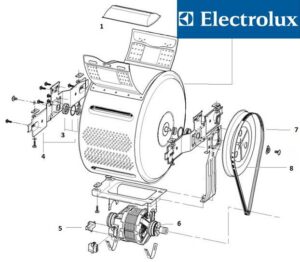

- The operating principle of a modern drum-in-tub is based on direct drive technology. The washing machine's inverter electric motor is connected directly to the drum, rather than via a drive belt, as was previously the case. This allows the motor to immediately engage the drum pulley upon receiving a command from the module.

- At the end of the wash cycle, the machine will drain all the used liquid, for which the control board will instruct the drain pump to pump out the used water from the tank.

- Afterwards, the inlet valve will be commanded again to fill the machine with some clean water. This is done to quickly rinse the tank and then drain the dirty water.

- Finally, the device will begin to draw water again, but this time much more, so that it is enough to rinse items covered with powder or gel.

- The rinsing process itself begins, during which the fabric will be freed from the remains of household chemicals.

- Once the rinse is complete, another portion of dirty water will go into the drain, and the control module will activate the spin cycle.

- The spin speed depends on the user settings and the capabilities of the machine, so the number of revolutions per minute can be as low as 800 or as high as 1400-1600.

The higher the RPM, the higher not only the spin speed but also the risk of damaging the fabric. Therefore, experts do not recommend spinning delicate fabrics at a speed greater than 800 RPM.

- The centrifugal force that pushes water out of the clothes during spinning helps spin laundry. At this stage, the washing machine shakes and makes a lot of noise because the drum speed reaches its maximum, which doesn't happen during a wash cycle.

- When the spin cycle is complete, the control module will command the pump to empty the tank, then stop working and turn off the washing machine.

- The final stage is unlocking the hatch, which will be performed some time after the end of the working cycle, as the bimetallic plate inside the hatch locking device must have time to cool down.

Why is there a heavy block inside the machine?

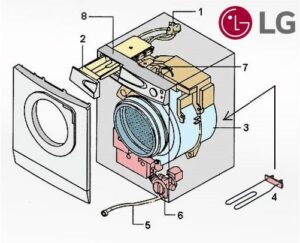

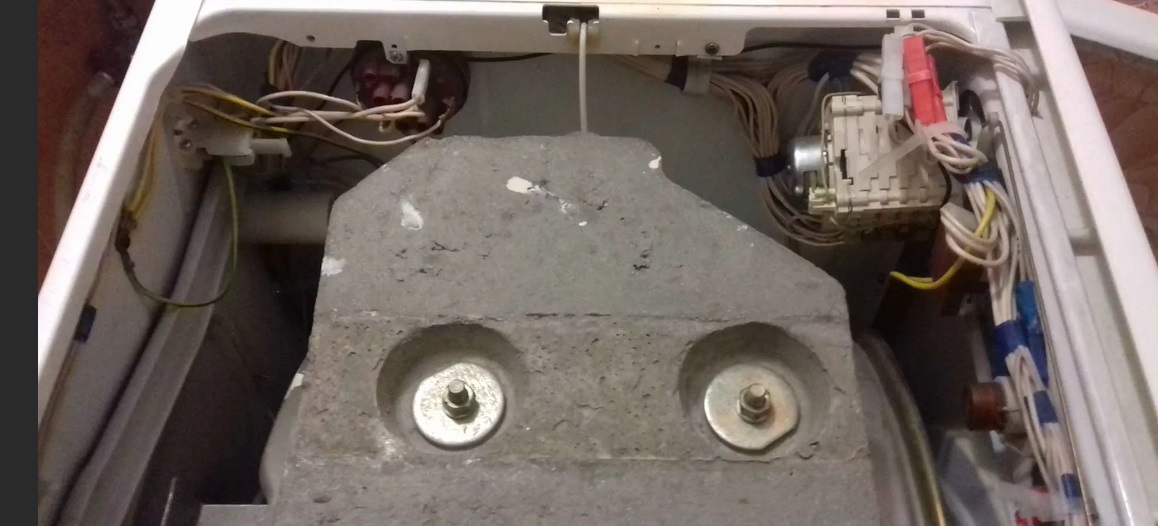

Users often want to see the internal structure of their "home assistant" with their own eyes, which is why they open the top cover of the case. There is nothing wrong with this if the manufacturer's warranty has already expired, otherwise it is better not to open the top cover of the CM case, so as not to lose the warranty service. Once you remove the lid, you can see the fill valve, dispenser, pressure switch, control module, and the huge counterweight that makes the machine so heavy.

The answer to the question of why this heavy block is needed inside is very simple. It is this counterweight that supports the washing machine during the wash cycle and the spin cycle. Without the concrete counterweight, the centrifugal force would cause the machine to swing so violently that it would tip over or simply bounce around the bathroom. Therefore, the larger the counterweight, the better for the appliance. However, sometimes this rule is not followed; in the case of narrow washing machines, manufacturers typically reduce the counterweight to fit within the compact unit's frame, which compromises the machine's stability.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment