How to choose a capacitor for a washing machine motor?

It's great when you can connect a motor to the correct voltage. But sometimes a situation arises where a three-phase motor must be powered from a single-phase network. For example, if a DIYer takes a washing machine motor and builds a lathe or other DIY project on it, they'll have to use a capacitor for the washing machine motor. But there are a variety of them, so it's a good idea to understand how to choose the right one.

It's great when you can connect a motor to the correct voltage. But sometimes a situation arises where a three-phase motor must be powered from a single-phase network. For example, if a DIYer takes a washing machine motor and builds a lathe or other DIY project on it, they'll have to use a capacitor for the washing machine motor. But there are a variety of them, so it's a good idea to understand how to choose the right one.

If you need to start a three-phase motor

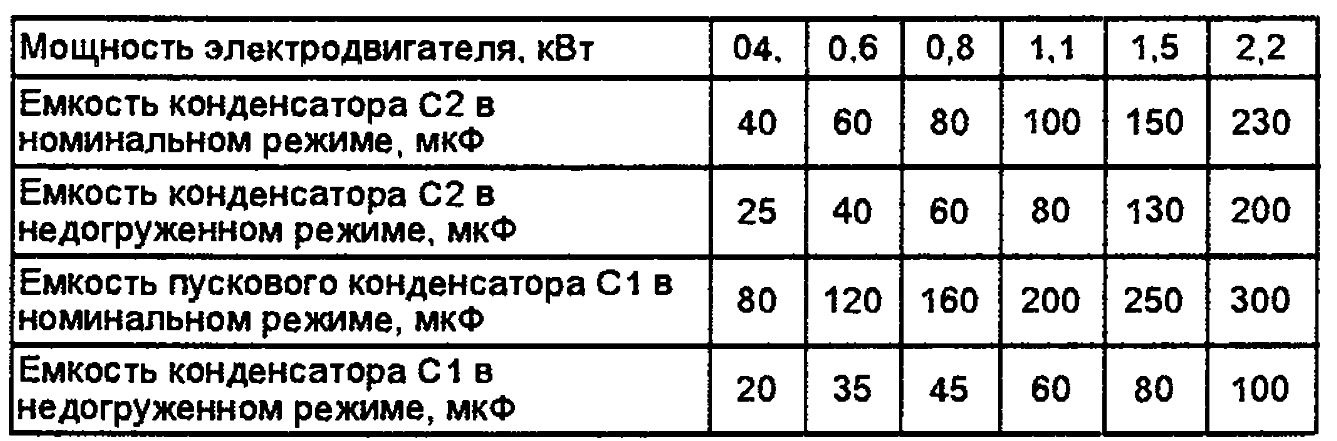

Selecting a capacitor for a washing machine motor isn't easy. The most important thing is to correctly determine the device's capacitance. But how do you calculate it? A more complex formula is used for a more accurate calculation, but a simpler approach is also available.

How can you quickly figure out which device is right for you? To calculate the capacitor capacity using a simplified method, you need to know the motor power and add approximately 7-8 μF for every 100 Watts. However, it's important to remember to take into account the voltage applied to the stator winding during calculations. This value should not exceed the nominal level.

When starting an electric motor only under maximum load, a starting capacitor must be included in the circuit. This device operates for a short period of time—approximately 3 seconds—until the rotor reaches its peak speed.

When selecting a starting capacitor, it is necessary to take into account that:

- in terms of capacity, it should be 2-3 times higher than the working capacitor;

- Its nominal voltage must be 1.5 times higher than the network minimum.

The main function of the starting capacitor is to bring the electric motor rotor to the optimal rotation speed.

Once you understand the nuances, you can select both a line and starting capacitor for a three-phase electric motor. To avoid making mistakes, it's important to follow all recommendations.

Selecting a capacitor for a single-phase motor

In the vast majority of cases, capacitors for asynchronous motors are used for connection to standard voltage (220 V), considering the device is connected to a single-phase network. However, the process of using them is much more complex. Let's look at why.

Three-phase motors operate using a phase-shifting connection, while single-phase motors require a phase-shifting torque. This is achieved by adding an additional layer of rotor winding for starting. The phase is shifted by a capacitor.

Why is it difficult to select a capacitor?

Although there are no significant differences, different capacitors for asynchronous motors require different methods for calculating the permissible voltage rating. Typically, approximately 100 watts per 1 μF of device capacitance is required. These motors have several possible operating modes:

- A starting capacitor is installed, and an auxiliary winding layer is created (specifically for the starting phase). In this situation, the device's capacitance calculation will be as follows: 70 μF per kilowatt of electric motor power;

- A working device with a capacitor capacitance of 25-35 μF is installed. In this case, an additional winding and constant connection of the capacitor will be required throughout the motor's operating life;

- a network capacitor is used when the starting device is connected at the same time.

In any case, it's important to monitor the electric motor's heating level during operation. If you notice overheating of motor components, take immediate action. If a run capacitor is installed, its capacity will need to be reduced. Experts recommend using devices operating at 450 watts or more, as these are considered universal.

Even before installation, it is recommended to check the performance of the capacitor using a special device - a multimeter.

A starting capacitor is a small component in an electrical circuit that is essential for the engine to reach the desired speed as quickly as possible. This device maintains an optimal load on the motor.

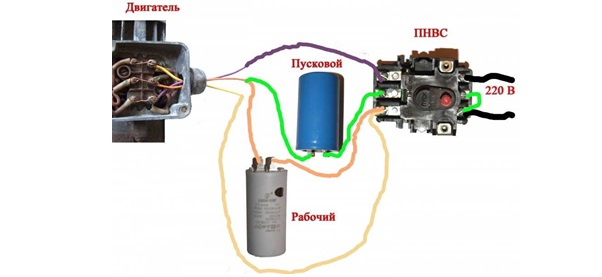

You can design a fully functional circuit yourself. Between the electric motor and the PNVS button, you need to install a working capacitor, and, if necessary, a starting capacitor. Typically, the winding terminals are located in the terminal part of the motor, so the connection can be upgraded in any way.

It's important to remember that the starting capacitor's operating voltage should be 330-400 volts. This is due to the power surge when the motor starts or shuts down.

So what's the difference between a single-phase asynchronous motor? This type of motor is more common in household appliances; its activation requires an auxiliary starting winding and a phase-shifting capacitor. It can be connected using a variety of available circuits. Three types of capacitors are commercially available:

- polar;

- non-polar;

- electrolytic.

Polarized connectors are prohibited for connecting electric motors to AC power. The dielectric inside the device will quickly deteriorate, causing a short circuit.

Therefore, in this case, non-polarized capacitors should be used. Their plates will interact equally with both the current source and the dielectric.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment