Homemade honey extractor from a washing machine

A novice beekeeper has no choice. They don't have the money to buy all the necessary apiary equipment, so they have to make do. For example, they can make their own honey extractor from washing machine parts so they're fully prepared when it's time to extract their first honey. We'll discuss how to do this in this article.

A novice beekeeper has no choice. They don't have the money to buy all the necessary apiary equipment, so they have to make do. For example, they can make their own honey extractor from washing machine parts so they're fully prepared when it's time to extract their first honey. We'll discuss how to do this in this article.

Preparing the washing machine parts

Most beginning beekeepers can't boast of a large number of bee colonies. Their farm will consist of 10-15 "boxes"—no more. This is precisely the number that a person with minimal experience can manage. There are a ton of nuances in this business, and quite a bit of work is required before a golden stream of sweet honey flows from the honey extractor's drain hole into the flask.

At the very beginning, you will have to think about what necessary equipment to purchase and what to make yourself. The beauty of beekeeping is that much of what you need can be done by hand, though it does require a lot of time and effort. Take, for example, a honey extractor. This essential apiary tool consists of three main components:

large capacity, which must accommodate the rotating subframes, their base, and the drive mechanism;

large capacity, which must accommodate the rotating subframes, their base, and the drive mechanism;- the drive mechanism itself, which consists of bevel gears, handles and a rotating base for the subframes;

- subframes that should move freely from side to side.

The question arises: how can an old washing machine help us? Old washing machines have fairly large wash tanks made of high-quality Soviet-era stainless steel. Stainless steel, as we know, is resistant to oxidation and easily cleans various stains. So, we'll turn the wash tank into our homemade honey extractor.

The drive mechanism and subframes will have to be made from other available materials: wire, parts of agricultural machinery, etc.

Additional materials and tools

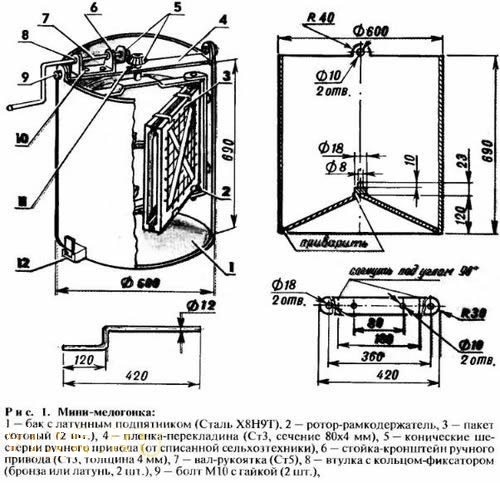

To make a homemade honey extractor, you'll need not only the washing tank from an old washing machine, like a "Sibir" or "Alma-Ata," but also other essential parts. To be clear, let's list them and show them in a drawing.

- A steel beam made of 4 mm thick metal and 80 mm wide. The length of the piece will depend on the diameter of the washing machine. Holes are drilled in the edges of the piece, and then these edges are bent.

- The drive mechanism bracket is made of metal, 4 mm thick and 80 mm wide.

- Handle for rotating the manual drive mechanism made of bent steel rod.

- The base that holds the subframes is made of 2 mm thick steel strips.

- Two subframes, which are made of thin steel strips and wire

- Two bevel gears - side and central. The central gear is larger in size than the side gear.

- Shaft for the central bevel gear. It's best to use a carbide steel rod of a suitable diameter for the shaft, as it will experience considerable stress during operation of the honey extractor.

- Honey discharge valve. The valve is made of a steel plate that is screwed to the bottom of the honey extractor, blocking the honey discharge opening.

All of the above parts can be obtained or manufactured for a small fee in a metalworking shop at any agricultural enterprise.

Now a few words about tools. Besides the standard set of tools found in every garage, we'll need a vice, anvil, sledgehammer, blowtorch, drill press, grinder, and a stainless steel welder. Nothing special, but it's hard to get by without the help of an experienced mechanic.

The process of assembling the device

A homemade honey extractor is very easy to assemble. You can assemble it yourself in 20-30 minutes, but only if all the parts are made and fit together perfectly. First, let's make the frames for the honey extractor.

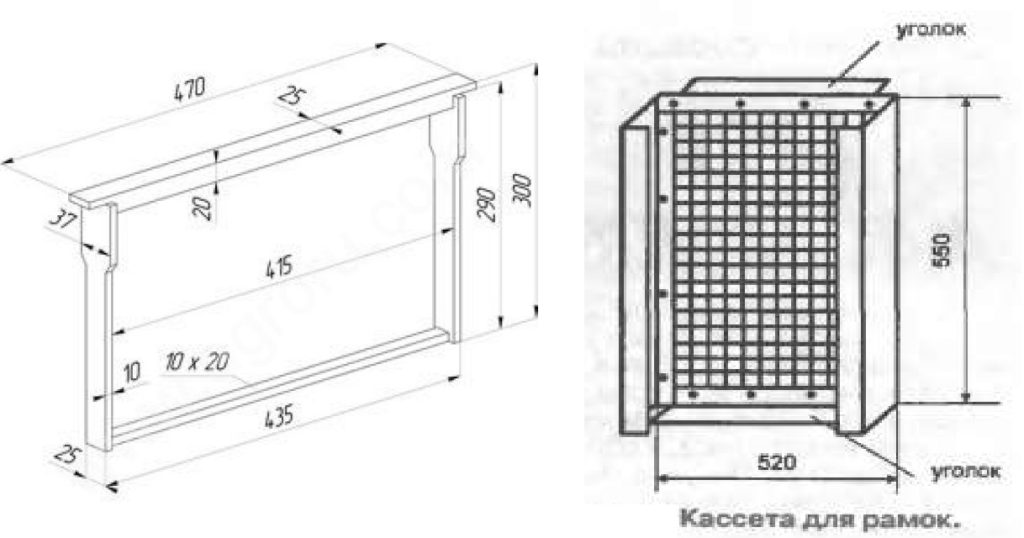

First of all, let's decide on the dimensions of the subframe. It must be able to freely accommodate a frame with dimensions of 435x300 mm. When making the subframe, we will focus on the body frame, and the store one, which is smaller in size, will definitely fit.

Taking into account the protrusions, the length of the frame can reach 470 mm.

We'll make a 520mm wide and 550mm high subframe from angle iron and wire. If you're certain you'll be using standard-sized frames, you can reduce the subframe's dimensions slightly, but it's best not to. So, what do we do?

- We take two stainless steel strips 1 mm thick and 520 mm long, and then two more strips 550 mm long, fold them into a rectangle and screw them together with bolts (you can weld them).

- Using a thin drill, you need to drill many small holes around the perimeter of the rectangle, and then, as shown in the picture above, stretch a wire mesh (use stainless steel and non-oxidizing wire).

- We make a second wire mesh, and then take 2 strips of stainless metal 1 mm thick and 40 mm wide and bend 2 channels from them.

- We attach wire mesh between the two channels, and we seal one end of the resulting subframe by welding a steel strip.

To prevent the subframe mesh from deforming under the influence of centrifugal force, one strip of metal must be welded crosswise to them.

- From one edge of the subframe, we screw two steel brackets directly onto the channel – one on top, the other on the bottom. We will need them later to attach the subframe to the rotor, which in turn we will immerse in the honey extractor.

- We make the second stretcher frame exactly the same way as the first. Then we set both hand-made stretchers aside.

Next, we need to work on the honey extractor's container. A washing tank can certainly serve as a good base for the honey extractor, but its bottom has quite a few unnecessary holes that need to be welded shut. We patch it with stainless steel sheets, take a stainless steel electrode, and weld all the unnecessary holes shut. Then we fill the tank with water. If the tank doesn't leak, everything is fine.

The next step is to create a drain hole for the honey. Since we've welded shut all the unnecessary holes in the bottom of the honey extractor, we'll have to make a new one ourselves. Use a drill and a step bit to drill a hole in the tank wall at the very bottom of the honey extractor. The diameter of the hole is 25 mm. Insert a rubber sealing ring into the hole.

Now take a rectangular steel plate and drill a hole in it. Drill a hole of the same diameter just above the honey extractor's drain hole. Place the plate on a bolt with two washers (one on the inside and one on the outside of the honey extractor). The plate needs to be slightly bent so that it can be moved to the side in case it is necessary to open the drain.

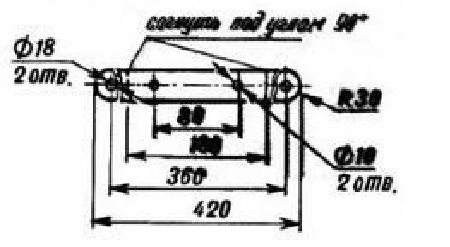

Next, we bend the honey extractor crossbar. We used a 4 mm thick metal strip for it, so we'll need to use a blowtorch to heat the edges and bend them at a right angle (or almost at a right angle) using a hammer and anvil. First, we'll need to drill holes in the ends of the crossbar for an M10 bolt.

Drill two more holes for the M10 screws, offset from the center of the part as shown in the figure above. You'll also need to drill two more holes to manually secure the drive mechanism bracket, but this can be done later, "on-site," so to speak.

A hole for the central gear shaft must be drilled exactly in the center of the crossbar. The diameter of the hole will be slightly larger than the diameter of the shaft.

Now place the crossbar in the middle of the tank opening, dividing it exactly in half, and mark the locations where we'll drill mounting holes in the tank walls to install the crossbar. Next, drill holes in the tank and screw the crossbar in place. Then, proceed as follows.

- We take a steel stud (the future shaft of the central gear) and cut threads on its ends.

- We insert the pin into the central hole of the crossbar, place the central bevel gear on top of it and secure it with a nut.

- From below, we place a rotor bar onto the stud. This bar is made from a 4 mm thick metal strip, according to the drawing below. The strip width is 15-20 mm.

- We fasten the bar with a nut and locknut. We drill holes in the edges of the rotor bar for the subframe studs. The studs are made from thin steel rods 570 mm long. The ends of the rods need to be threaded.

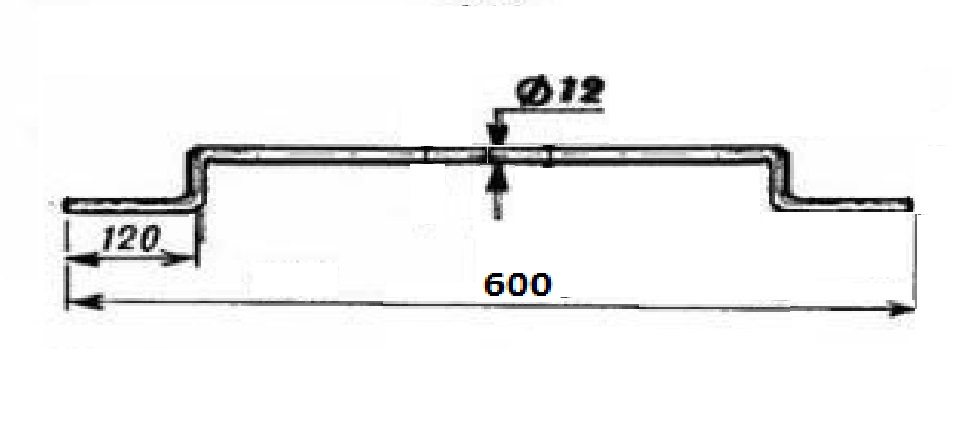

- We make a straight strip 600 mm long and 15-20 mm wide. We drill holes at the ends, just like with the curved strip.

- We insert the pins into the subframe brackets and simultaneously thread them through the holes in the upper and lower bars of the honey extractor's rotor mechanism. We secure the structure with nuts and locknuts.

We now have a honey extractor with a rotor and subframes that can be freely moved and inverted in one plane. Why do we need this? First of all, the invertible subframes allow for more efficient drying of the frames.

The thing is, when we insert a frame into the subframe and begin rotating the honey extractor, the centrifugal force causes honey to fly out primarily from the combs located on one side of the frame (the side facing the extractor wall). The combs on the opposite side of the frame remain full. To empty them, we turn the subframe with the frame over so that the combs, still filled with honey, face the extractor wall. After this, we rotate the rotor 100-150 times to completely drain the frames.

The honey extractor is almost ready. Now it's time for the drive. We'll use a manual drive, although there are also honey extractors with electric drives, which we'll discuss later.

We bolt the drive mechanism bracket to the crossbar. We thread the curved axle handle through the bracket, which we pre-thread. We place the gear on the end of the axle handle and secure it with nuts on both ends. The gear should be seated so that its teeth fit between the teeth of the central gear. The manual drive mechanism is ready!

You can wrap electrical tape or put a rubber sleeve on the other end of the handle-axle to make the handle comfortable to use.

Is an electric drive necessary?

Now a few words about what a homemade electric honey extractor is. In this case, it's still a honey extractor, only instead of a handle, it has a motor and shaft. Many people will say how convenient it is, how much easier it is to not have to turn the handle of the honey extractor, but to press a button and wait for the honey extractor to extract the honey automatically. In reality, it's more complicated than it seems at first glance.

A homemade professional electric honey extractor, like the one pictured above, has more than just a motor. It's also equipped with an electric control unit, which allows for convenient adjustment of the rotor speed, which is crucial. Even professionals using an electric honey extractor often break frames because they fail to reduce the speed of the rotating rotor in time, let alone beginners.

Imagine this: you have only 10 hives and you need to extract hundreds of super frames. You uncap the combs of the first batch of still-warm frames and load them into an electric honey extractor. You crank the rotor up to full speed to extract the frames faster and more efficiently, but end up breaking them all. Broken frames are not suitable for reuse; they either need to be remelted or reconditioned (reconditioning is not always possible). Ultimately, you've created a problem out of nowhere.

To control the speed of honey extractor rotors in large industrial apiaries, electronic control units with pre-programmed programs are used. These modules automatically decide when to increase and decrease the speed, ensuring the frames remain intact.

It's worth reminding novice beekeepers that a frame emptied of honey is returned to the bees, and if there's a "nectar flow," they immediately begin refilling it with honey. If you substitute a frame with wax foundation instead of a emptied frame, you'll have to wait for the bees to refill it, which wastes precious time and ultimately costs the beekeeper money.

What's simpler than a manual honey extractor? You can extract honey while carefully controlling the rotor's rotation. Not a single frame will be damaged, and there will be no loss. And even spinning hundreds of frames won't be a hassle. Conclusion: if you have a small apiary, use a manual honey extractor - an electric one is for owners of large apiaries (from 50 "boxes"). Well, if you're itching to use a washing machine motor somehow, read the article a machine made from a washing machine motor, it will definitely give you some useful thoughts.

In conclusion, for a budding beekeeper, there's nothing better than a homemade honey extractor made from washing machine parts. Firstly, it's relatively easy to make, and secondly, it's relatively inexpensive. Certainly cheaper than those sold in specialized beekeeping stores. So don't be lazy, grab some plans, dig out those old washing machines, and go for it. With the right amount of persistence and hard work, you'll succeed. Good luck!

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment