Which is better: mechanical or electronic control of a washing machine?

Modern automatic washing machines have electronic controls. New washing machines with manual transmissions are unavailable these days. There's a common misconception that washing machines used to be more reliable, but now they break down much more frequently. Is this statement fair?

Modern automatic washing machines have electronic controls. New washing machines with manual transmissions are unavailable these days. There's a common misconception that washing machines used to be more reliable, but now they break down much more frequently. Is this statement fair?

Let's figure out whether a washing machine with mechanical or electronic controls is better. What are the differences between the models? Which washing machine should you choose?

What is the difference between mechanical and electronic machines?

To understand which is better, you need to compare both options. Only by understanding the pros and cons of each control type can you draw conclusions. First, let's talk about the mechanics—these are the switches found on older washing machines.

The main advantage of mechanical control is reliability.

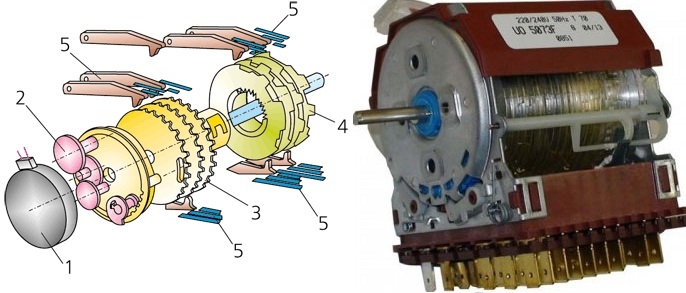

Washing machines with mechanical controls have timers. A switch moves at a predetermined speed for a predetermined number of minutes. When the cycle ends, the contacts close, deactivating the current program. The circuit is extremely simple, and therefore reliable.

What are the disadvantages of mechanical controls? Many components are constantly rotating. These parts wear out quickly. Therefore, owners of washing machines with mechanical controls have to replace rotary switches, clean the timer contacts, etc.

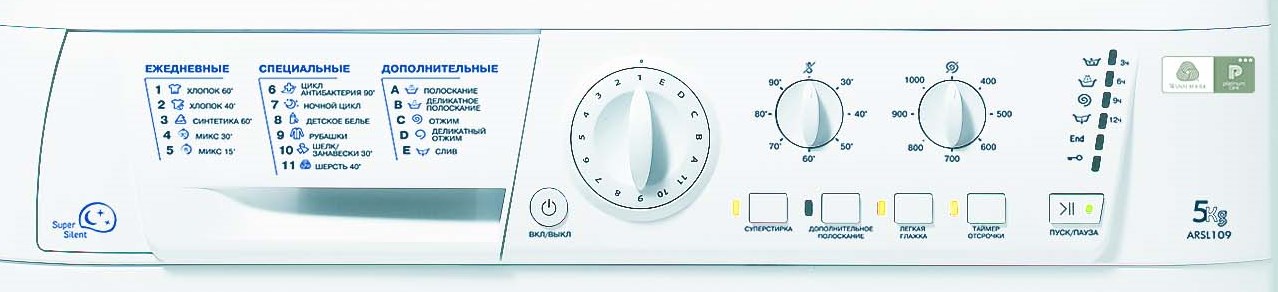

Electronic controls are complex. However, washing machine users don't need to delve into all the nuances. Thanks to the programmer and buttons on the dashboard, turning on and setting up the washing machine is simple. All the information is included in the equipment manual.

All modern automatic washing machines have electronic controls. Setting the cycle on these machines is very easy. The desired washing program starts in just a few seconds.

How electronics are superior to mechanics:

- minimum number of moving parts, which prevents premature wear of the system;

- a large number of additional options that increase the efficiency of washing (the ability to connect, for example, “Anti-crease”, “Hair removal”, “Soak”, “Delayed start”, etc.);

- equipping the washing machine with all sorts of useful sensors: overflow, auto-weighing, water temperature, etc.;

- the ability to monitor the progress of the cycle thanks to the display or indicators on the control panel;

- ensuring process safety (electronics respond to force majeure, turning off the machine in case of leaks, drum imbalance, or increased foaming);

- self-diagnosis of the system (machines with electronic control are able to identify any malfunctions that arise and notify users about them).

There are many advantages. Although mechanics are considered more reliable, electronics are more convenient, safer and more efficient.Washing machines with electronic control are more functional.

Electronic washing machines also have a drawback. These machines are very sensitive to power surges. A power outage can cause serious damage, including damage to the main processor.

Repairing the control module is a complex and expensive task. Sometimes it's easier to buy a new washing machine than replace the electronic unit. However, you can play it safe by connecting the machine to the power supply through a voltage stabilizer.

So, which is better? Electronics are undoubtedly superior to manual controls. Using a machine with electronic controls is more convenient and safer. Simply start the program with a couple of buttons and wait for the cycle to complete. With manual washers, you have to use a timer to set the duration of each stage—wash, rinse, and spin.

The reason for the durability of mechanical washing machines

The fact is, older manual washing machines last longer than their fully electronic counterparts. Our grandmothers still have machines made 30-35 years ago. But the reason has nothing to do with the control system. It's more to do with the mass production of automatic machines these days. Previously, they were built for quality, using expensive materials; now, it's all about speed and keeping costs as low as possible.

In the past, no one skimped on components. Machines were assembled from robust parts, the quality of which was strictly monitored. Every washing machine was tested before entering the market. The tub was made of stainless steel, the body of expensive plastic, and the weights of cast iron.

Nowadays, intense competition is forcing manufacturers to reduce machine costs. Washing machines are assembled on a production line by robots. The materials used are not always of the highest quality. Counterweights are made of concrete, and the washing machine tub is made of plastic.

Mass production increases the rate of manufacturing defects. However, modern automatic washing machines, even with more advanced electronic controls, are more affordable. Today, every family can afford a washing machine, whereas previously, it was considered a luxury. However, most modern models also have a shorter lifespan than their predecessors.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment