How to make a motor wheel from a washing machine?

Electric bikes are gaining popularity, but the cost of both the bikes and their components remains high. However, there's an alternative: building a motorized wheel from a washing machine yourself. An LG direct-drive motor from a washing machine is ideal for this purpose, as it's cheaper on the used market than other inverter motors. Finding a motor for the future wheel is easy, but fitting it into place is a challenge. We'll try to describe all the intricacies of making this homemade electric bike.

Electric bikes are gaining popularity, but the cost of both the bikes and their components remains high. However, there's an alternative: building a motorized wheel from a washing machine yourself. An LG direct-drive motor from a washing machine is ideal for this purpose, as it's cheaper on the used market than other inverter motors. Finding a motor for the future wheel is easy, but fitting it into place is a challenge. We'll try to describe all the intricacies of making this homemade electric bike.

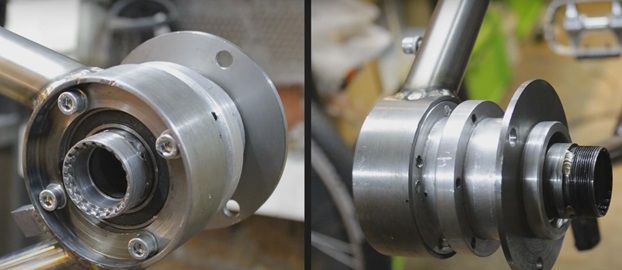

Need a step bearing and mounting disc

The idea of using a washing machine's electric motor as the basis for a bicycle hub motor isn't new. This option offers significant savings: while brand-name electric bike components cost between $50 and $70, LG inverter motors can be found for $8 and $10. The final cost will depend on the age and power of the machine.

The engine's load capacity is determined by the machine's capacity. LG models can have a tank capacity ranging from 3-5 kg to 10-12 kg. Consequently, the engine's power will vary between 300-1000 W.

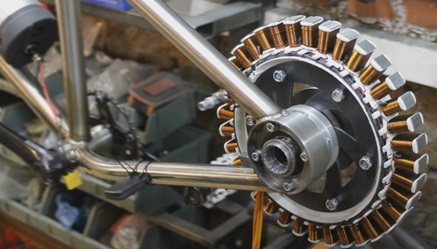

Inverter motors from LG automatic machines are suitable as the basis for the motor wheel for an electric bike.

Selecting the right motor power is only the first step. Building a motor wheel yourself also comes with a number of disadvantages:

- the washing machine motor has only a stator and a rotor (without a bearing and hub);

- Additionally, a mounting ring for the stator will be required;

- the washing motor has an incorrect winding;

- there will be problems with installing the spokes on the wheels.

Installing a washing machine motor onto a bicycle wheel is quite difficult. An old motor only has a stator and rotor, which, without a drum shaft outside the washing unit, don't engage or center. To adapt the unit to an electric bike, you'll have to find a wheel bearing and perform a series of turning operations to create a suitable seat.

A mounting disc for the stator also needs to be fabricated. It can be cut from a sheet of metal using a laser cutter. If you don't have one, a drill press and an angle grinder will do.

Problems with the winding

The third issue concerns the winding. Electric motors from automatic bicycles use aluminum windings, which is not suitable for electric bikes. Furthermore, the wiring is designed for 220V, while bicycle controllers only supply 72V.

As a result, there are two options left:

- rewind the winding (instead of aluminum, use copper);

- replace magnets.

Washing machine motors are equipped with ferrite magnets, which must not exceed their maximum rated power. Magnetization is also difficult, as each unit has four poles. Some technicians heat the device, weakening the magnets, or knock them out with a hammer. More suitable neodymium magnets are installed instead. However, it is necessary to additionally reinforce the rotor bowl with a steel ring, creating a locking system for the magnetic fields.

Improving the magnets on an LG motor will require a lot of effort and money. The extra expense increases the cost of the homemade product, making it pointless—for the same price, you could buy a dedicated motor for an electric bike. As a result, most craftsmen take the easy way out: they replace aluminum with copper, adjusting the voltage.

How to lace a wheel?

Difficulties will also arise with installing the spokes. The rotor bowl from the washing machine doesn't have protrusions with holes—they'll have to be made from scratch. Then the rods are inserted and welded to the rims.

If you have experience working with electronics and access to various equipment, you can take a chance and turn an LG motor into a fully functional and affordable hub motor.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment