Why isn't my washing machine motor working?

If your washing machine's motor fails, you can assume the machine is "dead." No washing can be done until the motor is replaced. But before replacing it, you need to understand what exactly happened and what's causing the problem. You can perform this diagnostic yourself, without the help of a technician. Let's look at how to figure out why your washing machine's motor isn't working and what to do next.

If your washing machine's motor fails, you can assume the machine is "dead." No washing can be done until the motor is replaced. But before replacing it, you need to understand what exactly happened and what's causing the problem. You can perform this diagnostic yourself, without the help of a technician. Let's look at how to figure out why your washing machine's motor isn't working and what to do next.

What kind of motor is inside your washing machine?

The motors found in absolutely all washing machines worldwide fall into three groups. There are asynchronous motors, which are almost never found today but are typical of older models; commutator motors, which are the most common; and inverter motors, which are found only in newer models.

Diagnosing an inverter motor is the most difficult due to the specifics of its assembly. This type of motor requires self-diagnosis, and the system immediately displays an error code on the display if something is wrong. As for commutator and asynchronous motors, their design is similar. For diagnosis, it is necessary to disassemble the motor and remove the motor.

In collector motors, these types of faults are most common.

- Brushes wear out. Graphite wears off over time anyway, but this process accelerates if operating instructions are not followed and the machine is overloaded.

- The lamellas on the collector peel off due to voltage surges or short circuits in the networks.

- Interturn short circuit or open circuit in the stator or rotor windings.

As you can see, there are plenty of possible causes for failure. So if the engine stalls, it's worth disassembling the car and inspecting the engine.

How do you remove different types of motors?

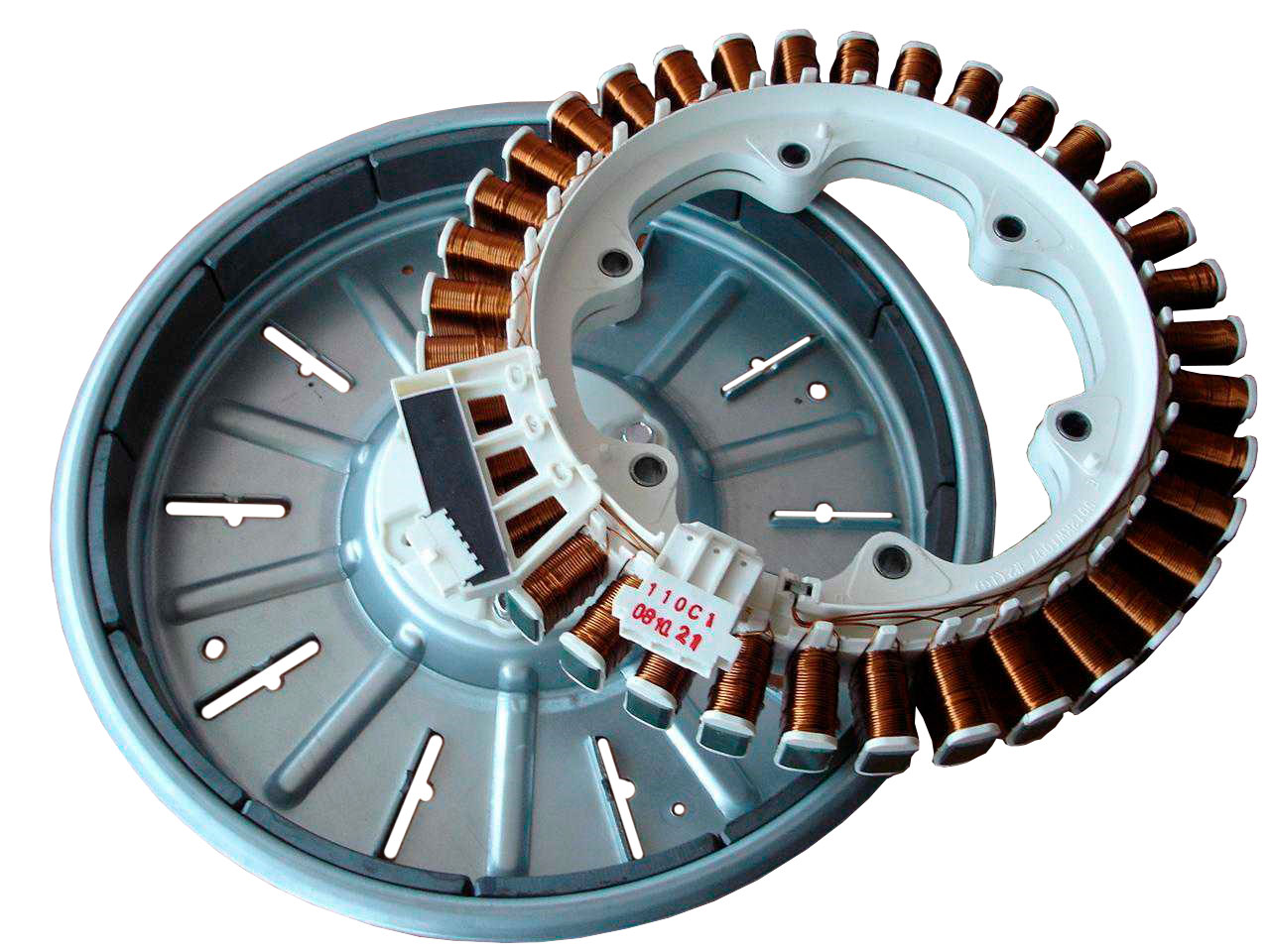

The difficulty of diagnosing inverter motors was mentioned above. What I meant was that while it's possible to remove the motor and inspect it visually, if repairs are needed, they can only be performed at a service center. Previously, such motors were found only in the latest LG and Samsung models, but they are now increasingly being installed in other brands. Let's get to this type of motor.

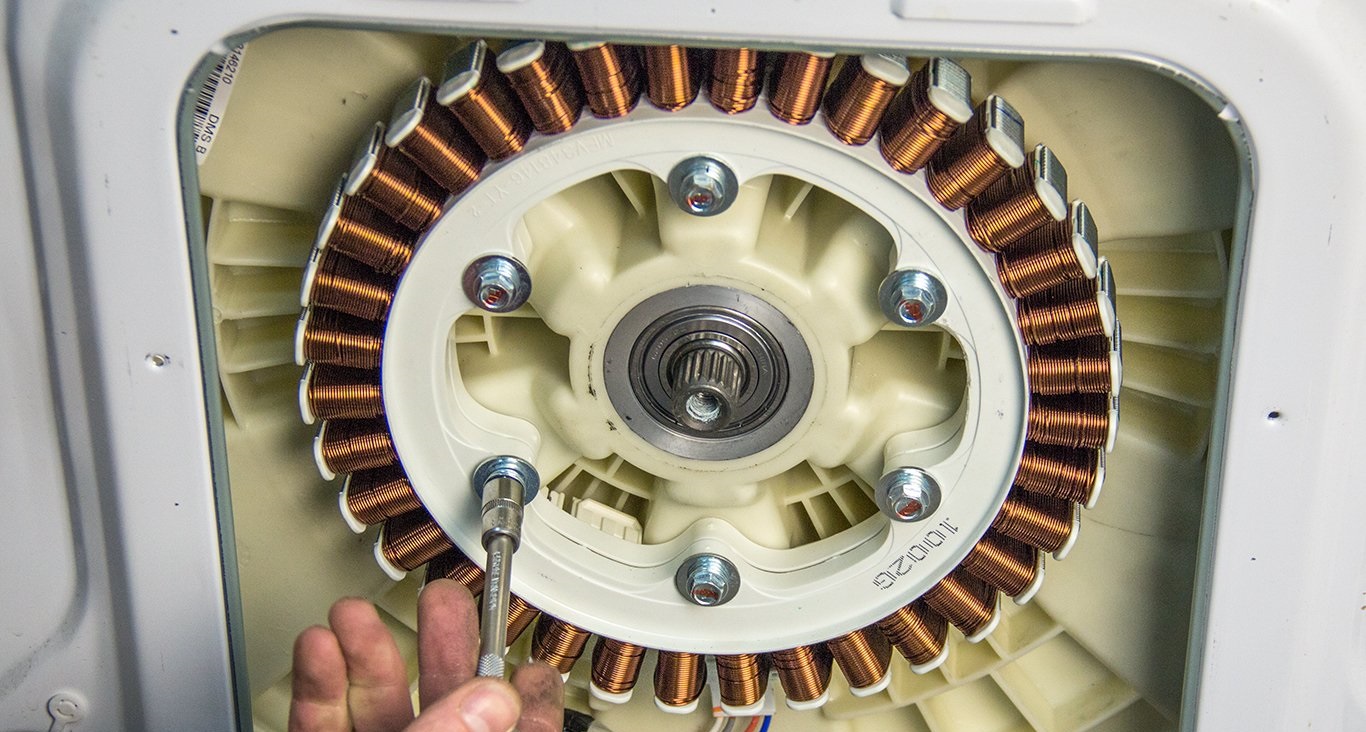

- Disconnect the machine from communications.

- Remove the rear wall.

- We remove all the wiring, disconnecting the connectors.

- Fix the pulley in a stationary position and unscrew the bolt in the center.

- Discard the rotor assembly.

- Remove the stator assembly by removing the fasteners around the perimeter of the assembly.

- Remove the stator.

- Disconnect the stator wiring.

If you discover any burnt parts during inspection, contact a professional technician. If the motor winding needs replacing, it's easier to buy a new motor and install it.

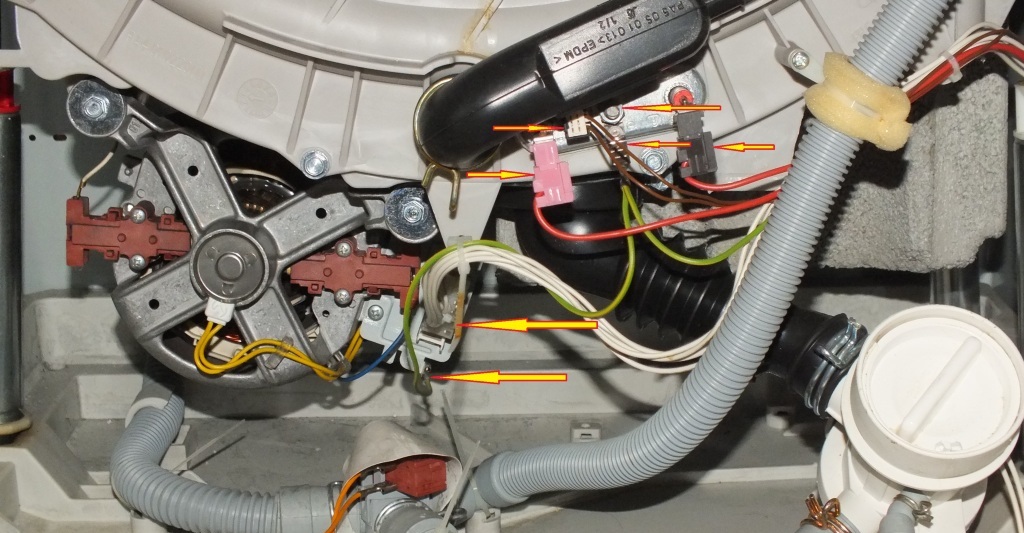

Commutator motors are very common. Almost all budget brand cars (Candy, Indesit, Ariston) are equipped with this type of engine.

We dismantle the collector motor:

- remove the back panel and inspect the space under the tank;

- disconnect the wiring contacts, having first fixed the position of the terminals in the photo or drawing;

- remove the fasteners and remove the motor from the housing.

Important! To make removing the motor easier, after unscrewing the bolts, slide it toward the heating element. This will allow the motor to easily slide out of the grooves and into your hands.

Checking the engine components

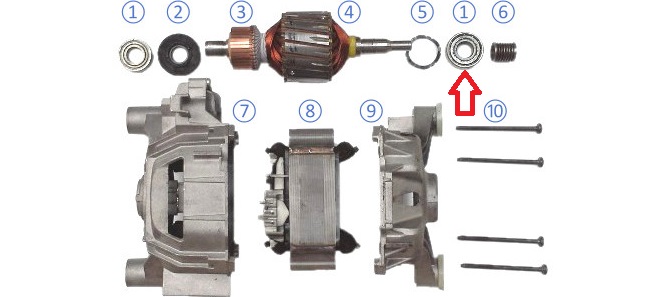

The first cause of motor problems is the brushes. The graphite material wears out from friction, causing contact to be lost and the motor circuit to become damaged. The motor suffers from a lack of power, starts and stops erratically, and malfunctions.

You can also tell if there's a problem with the brushes if sparking and a characteristic unpleasant odor occur when the machine is plugged in. The brushes are located on the sides of the housing. Remove their fasteners and inspect them in good light. You'll immediately see the worn surface. Even if it seems like only one brush is critically worn, both will need to be replaced, otherwise the force on the rotor will be uneven, leading to interruptions in operation. Replacing the brushes is done in reverse order.

The lamellas, in turn, wear down from contact with the brushes, which can bore entire cavities into them. If the rotor shorts or jams, the lamellas may peel off. A visual inspection will help identify the problem. If you see any roughness or small protrusions, remove the armature and resurface it on a lathe. Clean the gaps between the lamellas. The lamellas' performance after resurfacing can be determined with an ohmmeter. You need to clean the gaps until the device stops showing a short circuit. You can also detect problems with the slats by spinning the rotor. A loud noise indicates a problem.

Motor bearings are also subject to wear and tear, and their wear causes problems. The stator begins to rub against the rotor. Sometimes the problem is detected too late, and the rotor already shows signs of wear, requiring replacement as well. A faulty rotor rotates unevenly, stumbles, and makes a scraping noise. What should I do to remove the bearings?

- Depending on the size of the bearing, purchase a special puller.

- Install it by placing emphasis on the inner ring.

- To install the bearing on the shaft, it can be heated with a blowtorch.

- Once the bearing has cooled, it will fit into place like a glove.

The worst thing that can happen to a motor is a burnt-out winding. Replacing it yourself is impossible; it's easier and cheaper to install a completely new motor. You can determine the functionality of the contacts by simply testing them with a tester. A winding problem can be indicated by a loss of motor power and a loud humming sound, but no rotation. This causes the motor to overheat, triggering the thermistor, and preventing the washer from starting.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment