Why doesn't the spin cycle work in my semi-automatic washing machine?

Semi-automatic washing machines are quite simple in design. These units are inexpensive, making them popular among buyers—they're often installed in summer cottages, rental apartments, and other homes. But even these reliable and simple devices can malfunction. Owners of semi-automatic washing machines often encounter problems with the spin cycle. Let's explore why centrifuges malfunction and how to repair your "home helper."

Semi-automatic washing machines are quite simple in design. These units are inexpensive, making them popular among buyers—they're often installed in summer cottages, rental apartments, and other homes. But even these reliable and simple devices can malfunction. Owners of semi-automatic washing machines often encounter problems with the spin cycle. Let's explore why centrifuges malfunction and how to repair your "home helper."

What causes centrifuges to fail?

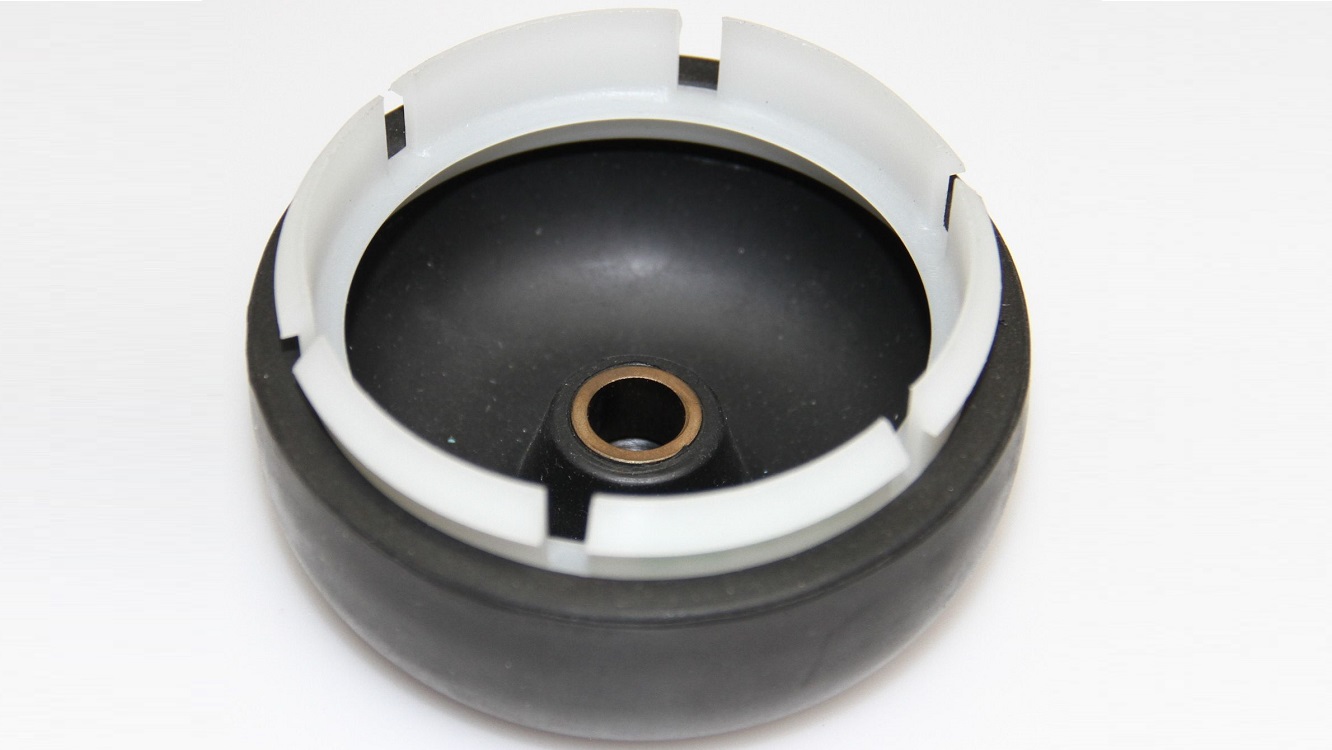

To be honest, the centrifuge is the most vulnerable part of the SMP. The unit is made very simply – the container is directly connected to the electric motor shaft. The only thing that protects the motor from water ingress is the seal, which is attached to the tank.

The seal tends to wear out, so after some time of using the washing machine, water easily gets onto the motor, causing a short circuit in the engine.

The seal deteriorates not only due to the constant vibrations of a semi-automatic washing machine. It wears out even if the machine is not in use. When the rubber dries out, it hardens, causing cracks to form on its surface. Defective seals allow water to leak into the motor, causing a short circuit.

Therefore, if the motor stops driving the centrifuge, it's necessary to replace not only the motor but also the seal of the semi-automatic washing machine. This is the only way to protect the device from recurring leaks and breakdowns.

Why did the centrifuge stop?

You can identify the reason why your washing machine's spin cycle isn't working without the help of a professional. The design of a semi-automatic machine is very simple, so you won't have to spend a long time troubleshooting. The centrifuge usually stops spinning:

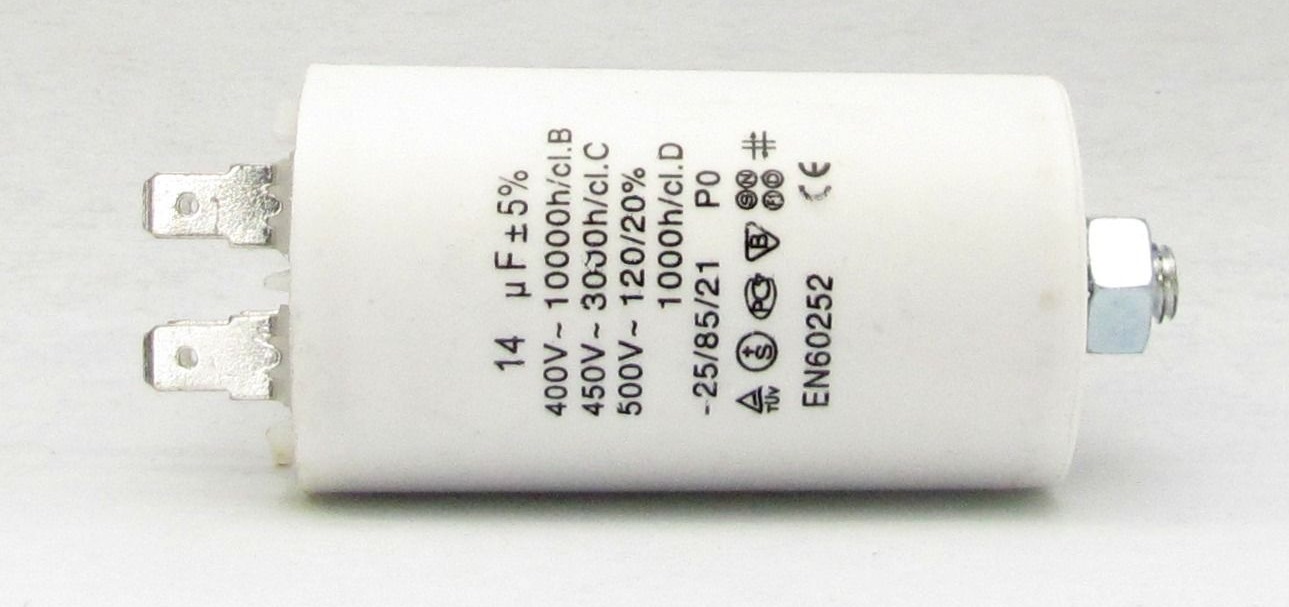

- due to damage to the starting capacitor of the electric motor;

- due to loosening of the brake cable.

Diagnosing the capacitor requires a specialized device. Therefore, the easiest way is to immediately replace it with a new part with the rated capacity. A sign that the element needs replacing is a strained, slow operation of the machine. It will be difficult to reach the desired speed, and the tank won't spin up to the required speed even after a couple of minutes. The cable can be checked manually. To do this, close the lid of the semiautomatic machine or close the test switch. Then try spinning the centrifuge tank. If it spins stiffly, tighten the cable to the factory settings.

If the starting capacitor and cable are in good condition, it's worth inspecting the centrifuge's walls. If there are cracks, it's likely that water from the tank has leaked onto the motor, causing a short circuit. In this case, you'll need to replace the drive and install a new seal. If you don't find any defects in the centrifuge tank, check the connections. Connections can be faulty for many reasons. It might be possible to repair the washing machine by replacing or tightening the cable.

How to get to the faulty parts?

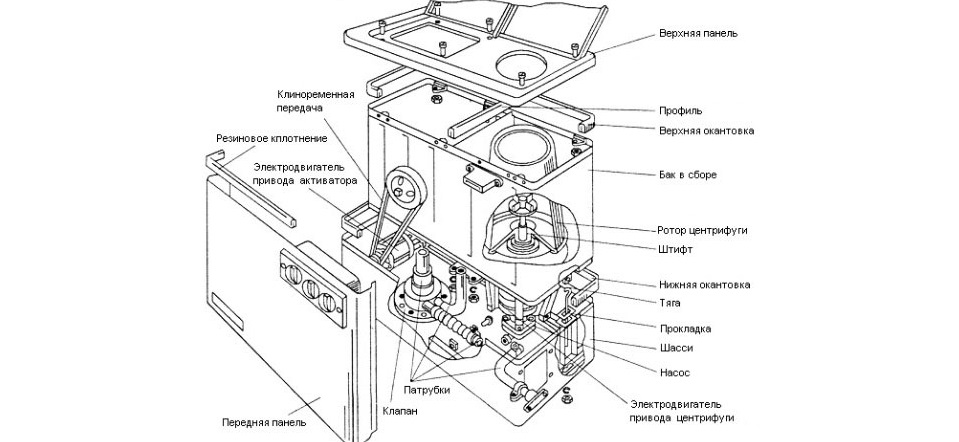

Semi-automatic washing machines from different brands are very similar. Of course, these are just the basic design features and variations in the layout of the components within the housing. Therefore, once you've disassembled your "home helper," you won't have any issues repairing other units. The procedure is as follows:

- Remove all the screws located on the semiautomatic machine body. Sometimes it can be difficult to find the screws, as manufacturers place the fasteners in hard-to-reach places. Therefore, it's best to have a long, thin screwdriver on hand;

- Unhook the water drain valve and the centrifuge brake pads. A small hatch in the rear of the housing allows access to these components.

- handle the centrifuge shaft.

The shaft locking screw is additionally secured with a nut. To remove it, you'll need a regular wrench and a socket wrench. Loosen the lock nut, and the bolt can be removed. Once the centrifuge shaft is removed, tilt the entire top section of the machine upward. Do this with gentle rocking motions to avoid damaging the components and the housing. Now you're ready to begin repairing the machine.

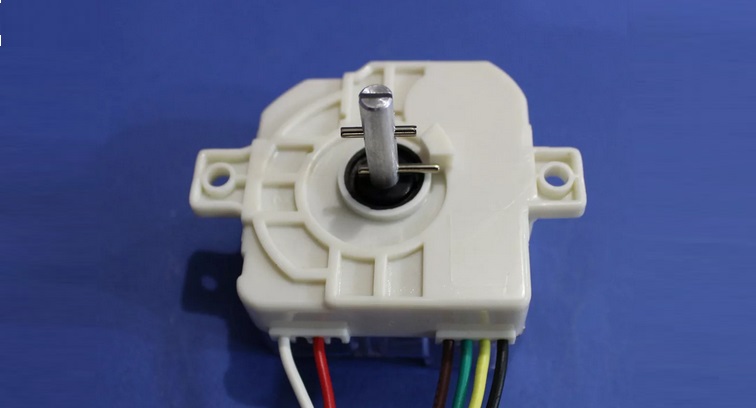

Automatic shutdown sensor

A safety sensor may be the reason your washing machine isn't spinning. Some semi-automatic models, such as Saturn and Daewoo, have one. It's located on the lid that covers the centrifuge. Its purpose is to prevent the machine from starting when the door is open.

To access the mechanism, you need to remove the top cover of the machine. Directly under the dashboard is the automatic shut-off sensor with two wires. The contacts should be cleaned with a cotton pad soaked in alcohol. Do not sand them or scratch them with a razor blade. This treatment usually helps restore the automatic shut-off sensor to working order. Check to see if the repair was successful. When the door is closed, the contacts should close.

Wash time adjustment mechanism

Sometimes a semi-automatic machine won't spin clothes because the timer is broken. The timer is also located under the machine's lid. To repair the mechanism, simply clean its contacts. Remove the dashboard and locate the timer—it looks like a clock with gears. Inside the mechanism are contacts that can melt after several years of use. They become coated with a layer of soot, preventing current from passing through.

Careful disassembly of the clock mechanism is essential. The gears are attached to the cover of the device, so remove it carefully to avoid spilling the gears. It's recommended to take a photo of the timer beforehand to avoid mistakes when reassembling it. Once you have access to the inside, wipe the contacts with an alcohol wipe.

Brake system

The braking system in semi-automatic machines works very simply. Brake pads are installed under the centrifuge tank and stop the tank when the door is opened. They are connected to the upper sash by means of a cable.

So, when opening the lid of the semiautomatic centrifuge, the user unknowingly tightens the cable. This causes the brake pads to grip the motor shaft, stopping the centrifuge. When the lid is closed, the pads should not touch the motor. Otherwise, the motor simply won't start. Therefore, be sure to check the cable tension and the position of the brake.

Motor

Quite often, a semi-automatic washing machine won't spin the laundry because the motor winding has burned out. This component can be checked using a special device – a multimeter. Diagnostics are performed as follows:

- Locate the ends of the wires coming out of the motor. Most models have three. The common cable is marked with an "N" symbol;

- set the multimeter to resistance mode;

- Measure the resistance between the common wire and each of the remaining two.

The tester screen should display the resistance value; if it is not displayed, it can be concluded that the motor winding is burnt out.

If the starting or operating winding burns out, the motor will need to be replaced. Rewinding the motor is impractical—the cost would be comparable to purchasing a new component. A replacement will restore the semi-automatic washing machine's functionality.

What else should I check?

It's difficult to list all the possible reasons why the spin cycle isn't working. Each brand of semi-automatic machine may have its own nuances. If the cable, motor, timer, sensor, and pads are all in order, check:

- drive belt. It may have broken or come off;

- Thermal relay. If the device malfunctions, it will have to be replaced with a new one;

- The fuse is located inside the housing, behind the rear wall. It's worth diagnosing the element if both the main tank and centrifuge motors are not working at the same time.

Small items that fly out of the centrifuge and become tangled around the motor shaft can interfere with the spin cycle.

Sometimes a semi-automatic washing machine won't spin if the laundry isn't evenly packed into the drum. The motor won't be able to spin the centrifuge, and the machine won't work properly.

Recommendations from experienced craftsmen

To disassemble a semi-automatic machine, you will need different tools. Before repairing, it's best to read the washing machine's instructions to understand what fasteners the manufacturer uses. This way, you won't have to worry about finding special tools. For example, to disassemble a Sibir semiautomatic, you'll need a special key. If you don't have the official tool, you can make one yourself using a 3/4-inch piece of pipe.

To remove the top cover on Fairy and Saturn models, you need to remove all the screws and slide the panel sideways. Also, if you can't find a couple of screws to disassemble the case, take a closer look – Krista and Daewoo washing machine manufacturers cover the screws with special caps.

Users may also have questions about removing the activator from the housing of Slavda washing machines. The unit itself is very smooth, making it impossible to grasp it and pull it up. The container can be removed by screwing two screws into the unit and grasping the protruding part. In fact, sometimes repairing an activator-type washing machine is much more difficult than an automatic one. However, most problems can still be resolved independently. Before beginning work, be sure to read the instructions for the appliance and understand its operation.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment