Vestel washing machine won't turn on

If the plug is in the socket, the power button is pressed, but the control panel is not lit, there's only one conclusion: your Vestel washing machine won't turn on. This situation is frustrating and frightening, and it seems like the only solution is to buy a new one. But the problem isn't always so widespread: many power issues can be resolved quickly and without a service call. The key is to diagnose and repair according to the recommendations and instructions. We'll explain step-by-step what to look for and where to start.

If the plug is in the socket, the power button is pressed, but the control panel is not lit, there's only one conclusion: your Vestel washing machine won't turn on. This situation is frustrating and frightening, and it seems like the only solution is to buy a new one. But the problem isn't always so widespread: many power issues can be resolved quickly and without a service call. The key is to diagnose and repair according to the recommendations and instructions. We'll explain step-by-step what to look for and where to start.

Let's identify "problem areas"

When a washing machine fails to start, it's immediately obvious. The control panel lights don't flash when plugged in, and pressing the buttons has no effect—the machine is silent. All indications are that the machine is disconnected from the power supply: no electricity is reaching the machine, and the system can't operate. Several causes of power failure can occur:

- lack of centralized power supply (in simple terms, there is no light in the room or apartment);

- sticking of the network button on the dashboard;

- malfunction of the power outlet for the washing machine;

- damage to the power cord or its plug;

- burnout of the interference filter (IF);

- break in internal wiring;

- failure of the control board or other electronic element.

The Vestel washing machine does not turn on if there are problems with the power supply: it is absent or does not “reach” the control board.

A comprehensive diagnosis of external electrical communications and the washing machine itself will help determine the cause of the failure. You will have to check all possible problems in sequence, from the wires and socket to the FPS and electronic unit. It's better to start with the electrical system and end with the internal problems of Vestel.

Electrics or FPS

The first step is to flip the switch. There may be no problem at all—there's simply a temporary power outage. Next, head to the electrical panel and check the circuit breakers and fuses. Sometimes, when several high-power appliances are plugged in at once, the line can't handle the current, causing the current load to surge and the RCD to trip. In this case, simply disconnect the extraneous devices and restart the system. Next, check the outlet. Often, the problem is obvious:

- dark spots are present;

- there is a burning smell;

- there is smoke coming from the socket;

- the socket body is melted.

If the electrical outlet is "clean," we check its functionality by plugging in any working appliance, such as a hair dryer or lamp. Does the appliance hum or light up? Then the outlet is intact, and we need to look elsewhere for the culprit. Is there no contact? The entire outlet will have to be replaced.

Having completed the external electrical check, we move on to diagnosing the Vestel washing machine. More specifically, its power cord. The cable and plug should be carefully inspected for signs of fire, and then the buzzer should be rung. If cracks are found or a leak is detected, local repairs using electrical tape or twisting are contraindicated. The cord must be replaced entirely!

The interference filter cannot be repaired – it can only be replaced with a new one!

The noise filter is checked next. The FPS is a small "jar" that protects Vestel electronics that are sensitive to voltage surges. When current surges occur, the device "triggers" and burns out, thereby blocking power to key components of the washing machine. If this happens, the element must be removed and replaced with a new one. You can determine whether the fuse/fuse protection system is burned out by inspecting it and using a multimeter. Here's how to proceed:

- disconnect Vestel from communications;

- remove the top cover (loosen the fixing bolts, move the panel back, and then lift it and press the latches);

- we find the place where the power cord connects to the washing machine;

- We look for a noise filter next to the power cord - a barrel-shaped element of black or white color;

- we disconnect the wiring from the FPS;

- We take the part out of the machine.

First, inspect the capacitor for dark spots and melted contacts. If everything appears fine, take a multimeter, set it to buzzer mode, and test the filter. Then measure the resistance: if the display shows "0" or "1," this indicates a faulty FPS. The part cannot be repaired; a new one must be installed.

The problem lies in the button

A stuck power button can also cause the washing machine to lose power. Older Vestel models are often prone to this problem—a stuck button cuts off power to the control board, shutting down the entire system. This is especially true if the machine doesn't have a moisture-proof control panel and is located in a bathroom or shower. Water gets under the cover and oxidizes the contacts, disrupting electrical circulation. To check the button's functionality, follow these instructions:

- remove the lid from Vestel;

- Find the power button on the back of the dashboard;

- disconnect the wiring from the key;

- pry up the plastic with a screwdriver, press the latches and pull it out.

The removed button is tested with a multimeter: first for breakdown, then for resistance. If a deviation from the norm is detected, you will have to remove the old button and install a new one. In some cases, stripping the wires can restore contact, but it's better to play it safe and replace the plastic one immediately.

The worst case scenario is that the module burns out.

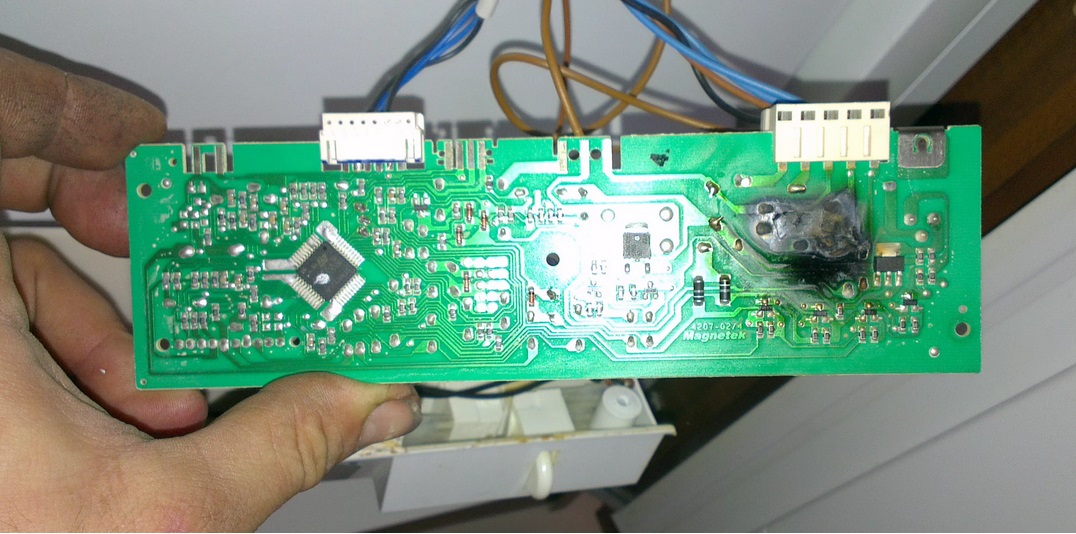

If the electrical connections, cable, FPS, and power button are all in order, there's only one possible problem: a malfunction in the electronic unit. This type of malfunction is considered the most difficult and expensive to repair. The fact is that the microcircuits, tracks and relays on the board are extremely sensitive to voltage fluctuations and burn out during sudden surges, disrupting the entire “chain”. It is difficult to identify the damaged element – there are dozens, and sometimes hundreds of them.

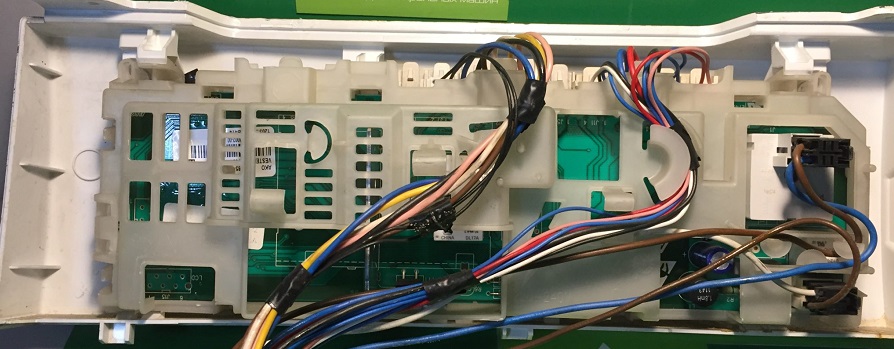

To diagnose the problem, the board needs to be thoroughly tested, which can only be done by a service technician. At home, you can only inspect the board—sometimes the fault is visible to the naked eye. Here's how to do it:

- fully extend the powder receptacle;

- in the freed hole we find and unscrew two screws;

- remove the top cover from the body;

- we unscrew the bolts that secure the instrument panel;

- we'll pry the panel in half using a flat-head screwdriver;

- we take out the board.

You should look for signs of a malfunction—stains, oxidized contacts, melted wires. If there are no defects, it's time to contact a service center. Often, the board fails unnoticed, and the fault is detected by a careful test. Testing the module yourself is not recommended—the slightest error will worsen the problem.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment