Ardo washing machine malfunctions

All large household appliances eventually break down. A trusted brand and high-quality European assembly don't guarantee trouble-free operation – user carelessness, manufacturing defects, and unstable power supplies often lead to breakdowns. Some manufacturers also have typical weak points. We suggest exploring the common faults of Ardo washing machines. We'll look at the signs of failure, diagnostics, and repair procedures.

All large household appliances eventually break down. A trusted brand and high-quality European assembly don't guarantee trouble-free operation – user carelessness, manufacturing defects, and unstable power supplies often lead to breakdowns. Some manufacturers also have typical weak points. We suggest exploring the common faults of Ardo washing machines. We'll look at the signs of failure, diagnostics, and repair procedures.

Common fault codes

Modern Ardo washing machines greatly simplify troubleshooting thanks to a built-in self-diagnostic system. Thanks to this system, the washing machine can automatically detect malfunctions and display error codes on the display.The user only needs to remember the combination and decipher it according to the factory instructions. If there is no screen on the model, the corresponding indicator will turn on.

Ardo washing machines are prone to problems with drainage, heating, and filling with water.

The self-diagnostic system database contains dozens of codes, but the Ardo most frequently displays three combinations: F2, F4, and F8. Each of these indicates a specific problem:

- F2 – no water heating (the heating element or temperature sensor is not working correctly);

- F4 – the drainage system is not functioning (the waste filter is clogged, the drain hose is clogged, or the pump is broken);

- F8 – tank overfilling detected (pressure switch failed).

The beauty of the self-diagnostic system is that it eliminates the need for a comprehensive diagnosis of the washing machine. The machine automatically pinpoints the problem, and the user simply pinpoints the fault and fixes it during repair. Simply decipher the correct combination using the instructions included with the Ardo.

Checking the heating element

A tubular electric heating element, or heating element for short, is one of the most vulnerable components of any large household appliance. This trend continues in Ardo washing machines. Moreover, the situation is exacerbated by the element's poor design. The coating used on it is considered substandard, as it doesn't protect against scale buildup but rather promotes its formation. As a result, the coil quickly becomes coated with a thick layer of limescale, overheats, and breaks, triggering the system's "F2" error code.

To prevent scale from settling on the heating element, it is necessary to organize a comprehensive water filtration system and regularly use special water softeners.

Operating a washing machine with a faulty heating element is strongly discouraged. Firstly, wash quality will suffer because the water will no longer heat up. Secondly, constantly trying to "warm up" the machine can damage the control board, causing it to freeze and fail. It's best not to delay; instead, diagnose the heating element yourself. Here's how:

- we turn the machine with the rear panel forward;

- unscrew the back and put it aside;

- we find a heater under the tank;

- we connect the probes to the contacts of the device;

- We evaluate the resistance indicators.

A functioning electric heater should have a resistance of 20-40 ohms. If the displayed value approaches zero, the device is faulty. It cannot be repaired; the only solution is to install a new heating element. Removing the heating element is simple. Simply disconnect the wires connected to the "plug," loosen the central fastener, press in the pin, and pull the element out. The heater is installed in the same way, only in reverse order. The main thing is to choose a suitable replacement - with an identical serial number and only from a branded supplier. “Foreign” devices will quickly break down or enter into “conflict” with the control board.

We check and change the pump

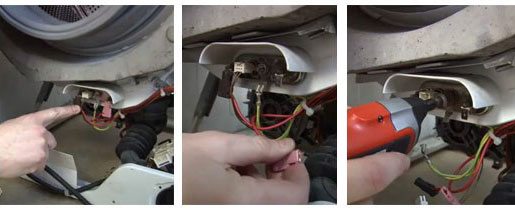

Common problems with the Ardo, as with many other machines, include drainage issues. This includes clogs and failures of all drainage components, from the debris filter and drain hose to the pump and impeller. To identify and fix the problem, it's necessary to check all of these components one by one. The drainage system can be accessed through the access door. This is a false panel at the bottom of the machine that can be removed with a screwdriver. Simply pry the cover open and release the clips. Then, proceed as follows:

- unscrew the debris filter and clean it from debris if necessary;

Be prepared! Water will spill out of the machine when you unscrew the filter!

- we wash the seat freed from the filter;

- We shine a flashlight through the hole and find the pump impeller – blades;

- Using a long object, we try to spin the impeller.

The impeller should spin freely. If the blades are difficult to move or stick, they are clogged with debris. You'll need to clean it, first removing the pump from the machine. For further inspection, lay the washing machine on its left side. It's important to proceed carefully and place a rug or pile of rags on the floor to ensure a soft and safe descent of the heavy machine. Access to the pump and impeller will be through the bottom. First, check the pump with a multimeter.

- We attach the probes to the contacts.

- We put the mark “up to 700 V” on the tester.

- We connect the washing machine to the power supply and start the “Drain” program.

- After 2-3 minutes, evaluate the values on the multimeter (if the pump does not hum at 220 V, it means it is faulty).

The pump cannot be repaired—it can only be replaced. First, we remove the old unit: disconnect the wires, unscrew the retaining bolts, press down on the housing, and remove it from its slots. Then, we take the new pump, secure it in its "socket," and replace the wires and hoses. Finally, we lift the Ardo to a vertical position and run a test wash.

It's the pressure switch's turn

If error "F8" occurs, the pressure switch must be checked. It is possible that the level sensor is broken or clogged, which is why it is not able to accurately assess the degree of filling of the tank.A quick diagnostic will help confirm your suspicion. Simply follow these short instructions:

- disconnect the washing machine from the power supply and cut off the water supply;

- unscrew and put aside the top cover;

- on the right side wall, find the pressure switch - a plastic “box” with a long tube lowered into the tank;

- find a tube that is proportionate to the fitting;

- detach the hose from the pressure switch housing;

- attach the found tube to the nozzle and blow into it.

Diagnosing the pressure switch also includes inspecting the hose connected to the sensor – it often wears out and lets air through, creating interference in measuring the pressure in the tank.

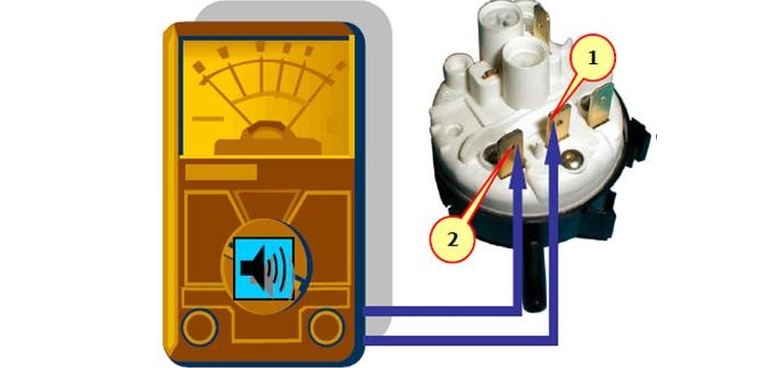

The air flow should close the contacts, which a working device will respond with a few clicks, while a broken one will remain silent. The diagnostics don't end there: inspect the hose for blockages or damage, and flush it under the tap if necessary. If a visual inspection reveals no problems, then test the device with a multimeter:

- turn on the tester to the “Ohmmeter” mode;

- we bring the probes to the sensor contacts;

- We evaluate the obtained resistance (changed readings will confirm the device is working properly).

If the pressure switch doesn't click, is damaged, or shows abnormal resistance, the relay needs to be replaced. Repairing it is pointless—a new sensor is inexpensive, and repairing it at home is nearly impossible. To replace it, purchase a new pressure switch and remove the old one. In the latter case, disconnect the pipes and wires connected to the sensor, loosen the clamps, and remove the device from the housing. Install the new relay in the reverse order.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment