Daewoo washing machine breakdowns

Automatic washing machines from this Korean manufacturer are known for their reliability and high build quality. However, like any other automatic machine, they are not immune to breakdowns. Let's explore the most common Daewoo washing machine malfunctions and explain how to repair the machine yourself.

Automatic washing machines from this Korean manufacturer are known for their reliability and high build quality. However, like any other automatic machine, they are not immune to breakdowns. Let's explore the most common Daewoo washing machine malfunctions and explain how to repair the machine yourself.

The most common defects

Before purchasing a washing machine, people tend to know the weak points of each brand's appliance. When it comes to Daewoo washing machines, there aren't any obvious weaknesses. The problems Daewoo users encounter are fairly common:

- failure of the pressure switch;

- clogging of the inlet mesh filter;

- A faulty thermistor. If this happens, the water doesn't heat up properly, and the machine may freeze during the wash cycle;

- Drive belt wear. This problem can manifest itself after several years of use. If the belt wears out after just six months of use, it's likely a manufacturing defect.

- Heating element problems. Heating element problems are usually caused by water that's too hard and poor maintenance. Scale builds up on the element, which can cause the part to burn out;

- Defective door seal. In most cases, the seal fails due to the user's failure to follow the washing machine operating instructions;

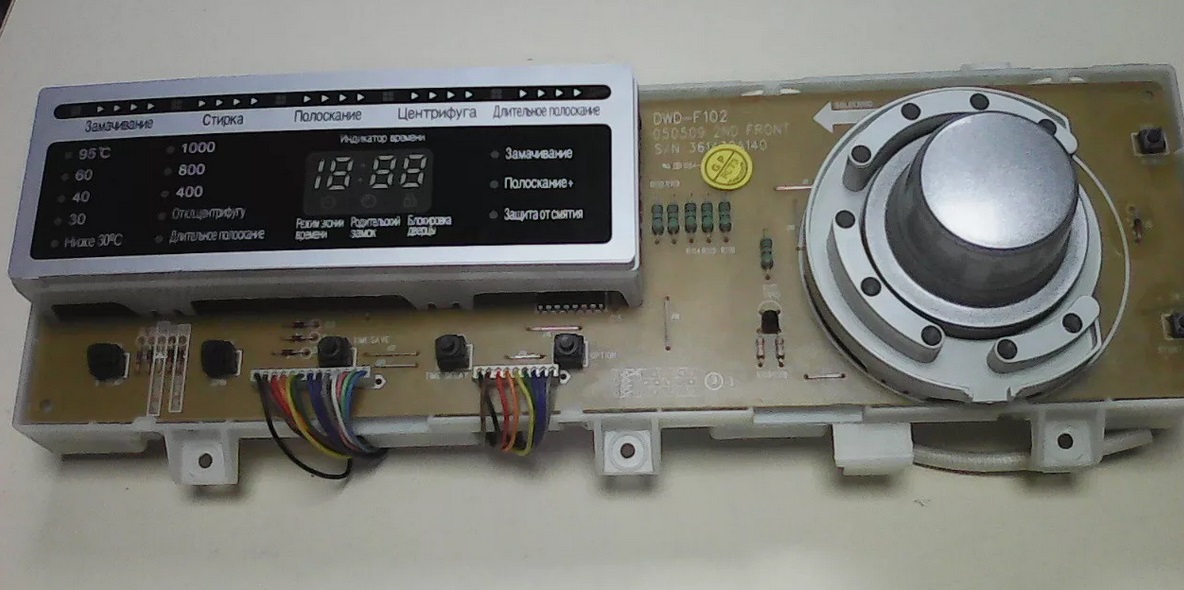

- control board failure.

Another weak point of Daewoo automatic machines is the drum. Over the years, it can rust due to excessively hard water. To prevent this, it's important to install a water softener filter at the inlet of the washing machine.

The listed faults are typical for both front-loading and horizontal Daewoo vehicles.

You don't need to call a professional to repair your "home helper." Most problems can be solved yourself. We'll explain what to do in each specific case.

Drive mechanism problems

Owners of Daewoo washing machines sometimes encounter the problem of the drum not spinning. The machine won't start washing because the centrifuge is stuck. The cause of this may be wear of the collector brushes, breakdown of the engine winding, failure of the tachogenerator or a break in the drive belt. If any of the listed faults occur, normal operation of the unit will be impossible.

To inspect the drive system components, you'll need to remove the rear panel of the housing. Once you have access to the components, you can begin diagnosing them. Inspect the drive belt. If it's not on the pulley, it's located underneath the machine. A broken belt is usually overstretched and needs to be replaced. A broken belt may be caused by:

- low quality of the rubber band;

- natural wear of the strap;

- constant overloading of the machine with things, which causes the drum to spin;

- loosening of the pulley fastening;

- factory defect of the drum "wheel".

To check the motor and Hall sensor, remove the motor from the housing. This requires unscrewing the two bolts holding it in place. First, inspect the commutator brushes—if the graphite rods are worn down more than 50%, they will need to be replaced (be sure to replace both brushes, even if one is intact). To test the tachogenerator, you'll need a multimeter. The same device is also needed to diagnose the motor's stator and rotor windings.

The system is clogged

Daewoo washing machines often stop working properly due to clogs in the system. In this case, it's very easy to restore the machine to working order yourself, without the need for a professional.

A slow or no drainage of water from the tank will indicate a blockage.

A blockage can occur in the following places:

- trash filter. This is where dirt most often accumulates;

- Pump. The pump on Daewoo cars rarely gets clogged because an additional filter element is installed in front of it;

- drain pipe. It connects the pump to the tank;

- Drain hose. This is a corrugated pipe through which water flows directly into the sewer.

What should you do in this situation? First, check the debris filter. On Daewoo washing machines, it's hidden behind the lower panel. Before removing the plug, cover the floor around the machine with dry rags and prepare a shallow container. Water will pour out of the hole, so be prepared.

After removing the dust collector, inspect it. Remove any debris from the coil and shine a light into the filter's slot. Remove any objects stuck in the hole and clean any dirt from the walls. Then, replace the plug. Next, inspect the drain hose. Feel the corrugated tube. If you notice a seal, disconnect the hose and clean it with a special brush. Then, reinstall the drain.

Next, you can disassemble the machine and clean the drain hose and pump. To access the pump, you'll need to unplug the wiring and remove a couple of bolts. To remove the hose, you'll need to loosen the clamps holding it in place. If the washing machine's drainage system is in good working order, but water still won't drain, there may be a clogged drain. Call a plumber to fix this.

Inlet valve, filter element, pump

A faulty solenoid valve's symptoms are unmistakable from any other Daewoo washing machine malfunction. If the inlet diaphragm is malfunctioning, water will either not enter the drum or, conversely, will flow into the system by gravity, even when the machine is unplugged.

If you notice a “gurgling” sound of water being collected and drained when the washing machine is turned off, check the inlet valve immediately.

First, remove the top panel of the Daewoo washing machine by unscrewing the two bolts holding the cover. The solenoid valve is located where the inlet hose connects to the washing machine body. Next, inspect the valve seals. If they are not deformed, test the part with a multimeter. If the resistance at the inlet sensor contacts is between 30 and 50 ohms, it is functioning properly. If the inlet valve is broken, it should be replaced; the component cannot be repaired. You need to purchase the part, unscrew the faulty sensor from the machine, install a new one, and connect all the hoses and wires to it.

If you notice that your Daewoo washing machine isn't draining and there's no sound typical of a pump running, you should check the pump. To access the component, you'll need to lay the washing machine on its side and remove the element through the bottom. Next, inspect the pump impeller, removing any hair or other debris from the element. Next, disassemble the element housing and clean out any dirt from the inside. The pump should also be tested with a multimeter to rule out a burnt-out component.

All of the "symptoms" described above may be the result of a problem with the electronic unit. Damage to the triacs or circuit board tracks will impair the washing machine's operation. Diagnostics and repair of the control module should be entrusted to professionals. Digging into the machine's "brain" with your own hands is dangerous - you can cause even more damage to the equipment.

Self-diagnostic system codes

Modern washing machines are capable of automatically detecting system malfunctions and notifying users. Machines equipped with a display will display the corresponding error code, while those without a display will alert users to problems by flashing the indicator lights.

The error codes are deciphered in the Daewoo washing machine manual.

If you notice that the washing machine has frozen and displayed an error, you should immediately open the user manual. The self-diagnostic system allows you to narrow the range of possible breakdowns and speed up the search for the cause of the malfunction. Let's figure out what each code indicates.

- Error OE. This indicates that your Daewoo washing machine is unable to drain water from the drum. You'll need to check each element of the drainage system one by one. Start with the debris filter and drain hose. Next, inspect the pump and hoses, and ensure the wiring between the pump and the control module is undamaged.

- The IE code indicates that water is not filling the system or filling very slowly. This error doesn't always indicate a malfunction. The water supply to your home may have been turned off or the pressure may have been reduced. It's also possible that the shutoff valve is closed. If the water supply is fine and the faucet is fully open, you'll need to check the washing machine's inlet valve, the filter mesh, and the inlet hose.

- Error UE. Indicates an imbalance in the drum. This usually occurs when laundry clumps together in the washing machine. Therefore, it's important to distribute the laundry evenly inside. The code may also appear if the machine isn't level. A less common cause is damage to the counterweight unit.

- LE code. The machine displays an error message without even starting the wash cycle. This error code indicates that the drum door is not closed properly or the door lock is faulty.

- Error E: This error code indicates a faulty load sensor. In this situation, the Daewoo washing machine will not start and the drum will not rotate. The element will need to be replaced.

- Code E indicates a problem with the pressure switch. You'll need to check the level sensor and ensure the connections are intact. If the element itself is broken, it will need to be replaced; the part is not repairable.

- Error H indicates that the water is not heating to the set temperature. This could indicate either a break in the heating circuit or a faulty heating element. If the element is damaged, it will need to be replaced.

If you notice your Daewoo washing machine has stopped working, don't panic. If it's still under warranty, it's best to call a service center; diagnostics will be free. Even after the warranty period has expired, you can tinker with the appliance yourself, determine the cause of the malfunction, and repair your "home helper."

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment