Gorenje washing machine breakdowns with a drum

The Gorenje line of washing machines includes models with a water tank. Due to this design feature, the machines can operate without a running water supply. The list of potential problems with these washing machines is the same as with standard automatic machines, but there are also some specific issues.

The Gorenje line of washing machines includes models with a water tank. Due to this design feature, the machines can operate without a running water supply. The list of potential problems with these washing machines is the same as with standard automatic machines, but there are also some specific issues.

What are the possible malfunctions of a Gorenje washing machine with a drum? Which components break most often? When can you repair the washing machine yourself, and when is it best to call a technician? Let's explore the nuances.

Problems specific only to machines with a tank

In fact, there are virtually no other brands offering models with a water tank like the Gorenje line. These machines are designed in no way to distinguish them from conventional automatic machines, except for the addition of an additional water tank. These washing machines can operate independently of a running water supply.

A separate tank attached to the washing machine body creates virtually no problems. However, users will need to additionally monitor the tank valve. This element often becomes clogged with dirt and impurities contained in the water.

If the tank valve is clogged, the Gorenje washing machine will not be able to fill and will display error F01.

How can this be avoided? It's important to fill the machine's reservoir with clean, preferably settled, water. This will ensure the filter does its job properly and prevent the valve from clogging. The inlet element is quite expensive, so it's best to prevent it from becoming clogged.

Another very rare, but possible problem is damage to the water tank. The tank is made of plastic and is therefore prone to deformation. Sometimes the tank bursts on its own, in other cases it is damaged by users.

If the crack is small, it can be soldered. If the damage is severe, the tank will need to be replaced. Another option is to rebuild the washing machine and connect it directly to the water supply.

Typical malfunctions of Gorenje washing machines

Gorenje automatic washing machines are popular among customers. The manufacturer offers unique equipment. Machines that don't rely on a running water supply are a real find. All Gorenje washing machines are also distinguished by high build quality, reliability, and advanced software.

As reliable as Gorenje washing machines are, they do have their weaknesses. The list of malfunctions is short, and most can be resolved independently, without the help of a technician. According to information provided by service centers, typical faults include:

- failure of the drain pump;

- heating element failure;

- damage to the control board;

- incorrect operation of the pressure switch;

- broken hatch door handle.

The drain pump is the most common problem with Gorenje automatic washing machines. Almost a quarter of repair calls are caused by pump malfunction. The washing machine simply stops pumping water into the drain.

Second on the list is the heating element. This is the weak point of any washing machine. Water in most regions is hard, so the heating element becomes coated with scale, its heat output is impaired, and it burns out. Replacing the heating element is easy; the job takes no more than half an hour.

Water level sensors rarely fail, but such failures have been reported by specialists. The repair is straightforward, and replacing the pressure switch can be done at home. Installing a new door handle is also very simple; you just need to find the right part.

The worst case scenario is when the control module fails. Repairing it yourself without the knowledge and experience will be difficult. The board is an expensive component, and to avoid making the situation worse, it's best to contact a service center immediately.

Problem with drain pump

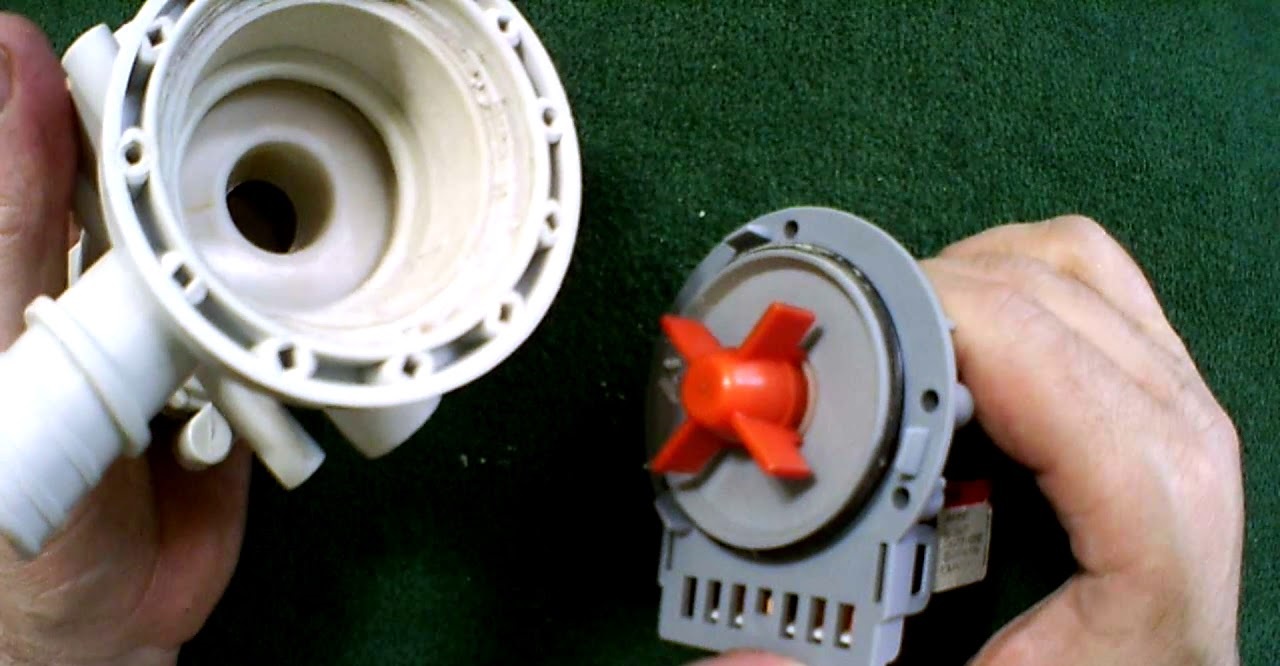

Pumps in Gorenje washing machines are the most vulnerable part. This is due to the design of the part. The moving parts of the pump are located close to each other, and the buildup of limescale causes them to become clogged and wear out faster.

Original Gorenje drain pumps are very sensitive to heavy metal impurities in tap water.

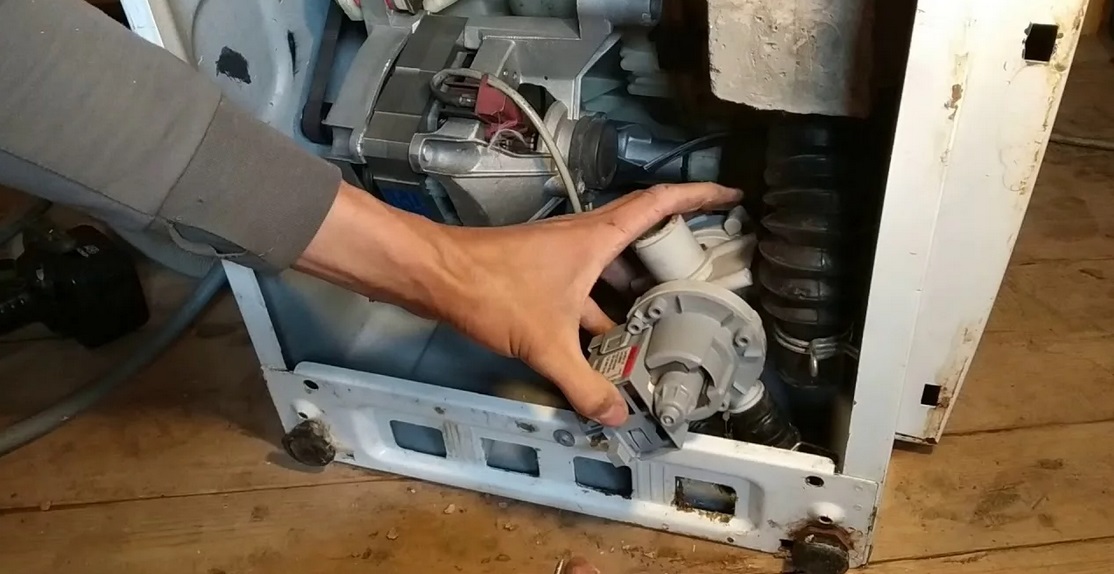

Pump failure can be prevented. To do this, monitor the hardness of the water entering the washing machine and use special softeners. If the pump is broken, you can replace it yourself, without the help of a professional. Here's how:

- de-energize the Gorenje washing machine;

- disconnect the device from the sewer;

- remove the powder container, drain the remaining water from it and put the cuvette back;

- move the washing machine to a place where it will be convenient to work with it (you will need 2-3 square meters of free space);

- lay the machine on its side, since you will have to reach the pump through the bottom of the washing machine;

- unscrew several screws holding the tray;

- Find the pump – it is located near the drain pipe.

Now you need to test the pump with a multimeter. Disconnect the plug and wires from the pump and measure the resistance produced by the component. Normally, it should be 160-200 ohms. If the tester screen displays a lower value, the pump is faulty.

The drain pump will have to be replaced. For washing machine repair Gorenje It is recommended to purchase original, high-quality components. You shouldn't save money and buy cheap analogues.

Removing a faulty pump is easy—just unscrew a few fasteners holding it in place. Next, install the new pump and secure it with bolts. Then connect the plug and wires.

Now you can replace the bottom of the washing machine and stand it upright. Be sure to run a test cycle without any laundry in the drum. Observe how your "home helper" works. If the water is pumped into the drain, the repair is complete.

This type of malfunction is easy to fix yourself. The key is to find the right replacement drain pump. If your Gorenje washing machine is new and still under warranty, don't even try to open the casing. Contact a service center immediately.

The heating elements are burning out

This problem is common in automatic washing machines of all brands. It's not even the washing machine itself that's at fault, but the water quality. Why do heating elements often fail?

- Water contains impurities. These deposit as scale on the heating element, impairing its heat transfer. As a result, the heating element burns out.

- Voltage fluctuations in the network.

- "Harsh" washing machine operating conditions. For example, when users run 2-3 high-temperature modes in a row without allowing the heating element to cool down.

If your washing machine stops heating water, don't ignore the problem. You'll need a multimeter to diagnose the heating element. Here's how to proceed:

- unplug the washing machine;

- disconnect the machine from the sewer;

- move the washing machine away from the wall or remove it from the cabinet/niche (you will need free access to the back of the case);

- unscrew several screws that secure the service hatch cover;

- remove the drive belt from the pulley;

- find the heater – it is located under the washing machine tank;

- Take a photo of the wiring diagram for the heater (this will help you avoid making mistakes during reassembly);

- reset the heating element supply wiring;

- Use a multimeter to check the resistance of the tubular heater.

The tester must be set to ohmmeter mode and set to the minimum resistance value. The multimeter probes are placed across the two outermost contacts of the heater. A functioning heating element will read between 10 and 30 ohms. If the display shows "0" or "1," the heating element needs to be replaced.

If the heating element is working properly, check the temperature sensor and the wiring in the heating element-thermistor circuit.

A burned-out heating element cannot be repaired. The element must be replaced. Here's how:

- unscrew the heating element fixing nut;

- Use pliers to push the central bolt inward (it is important to act carefully so as not to break the mechanism);

- grab the heater and use rocking motions to pull it out of its socket (if you can’t remove the heating element, treat the part with WD-40 lubricant and try again);

- clean the heating element seat from debris, dirt, and scale (don’t be afraid to stick your hand into the hole, you can find a lot of “interesting things” there);

- insert a new heater into the groove;

- secure the heating element with a fastening nut (it is tightened by hand, but not too tightly so as not to strip the threads);

- put the power wires back in place;

- Pull the drive belt onto the pulley and put the service hatch cover back on.

All that's left to do now is connect your Gorenje washing machine to the power supply and run a test wash. Select a cycle that heats the water to at least 60 degrees Celsius. After 15-20 minutes, touch the door glass – it should feel warm.

Control board

Another problem that Gorenje washing machine owners face is damage to the main module. Usually the control board starts to work incorrectly after sudden voltage surges in the network. To prevent this, it is better to connect the washing machine through a stabilizer.

Only an experienced specialist can professionally test the control module and determine whether replacement is required or whether repairs are sufficient.

What can you do yourself? Access the board and perform a visual inspection. Sometimes a single glance is enough to identify the source of the problem. The module may have burnt or oxidized contacts or bulging areas.

You can also test all the semiconductors on the board at home with a multimeter. This is a very painstaking task. You need to not only understand the control unit's circuit diagram but also know the resistance each element should produce.

Therefore, in such a situation, it's best to contact a service center immediately. Specialists will conduct a computer test of the control module. Only after a thorough diagnosis can a conclusion be made about the feasibility of board repair. In some cases, resoldering the tracks, installing new semiconductors, or cleaning the contacts will help. Sometimes, a complete replacement of the control module will be necessary.

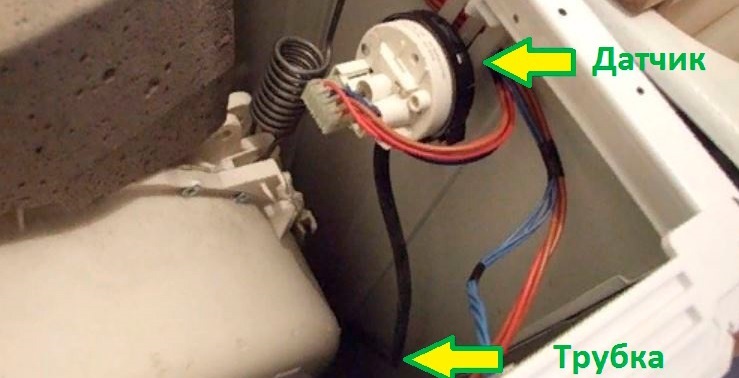

The pressure switch breaks down

All modern Gorenje washing machines are equipped with a self-diagnostic system. This intelligent system, if it detects a malfunction, will immediately alert the user. Error F3 or F43, displayed on the SMA display Gorenje, will tell you about the malfunction of the water level sensor.

It's possible to detect a faulty pressure switch even without the self-diagnosis system's help. The first "symptom" is a lack of water in the drum after starting a cycle. The machine may also activate the heater for some reason, despite the tank being empty.

A malfunctioning pressure switch will also be indicated by a continuous water filling of the tank. The machine will fill and then immediately drain the liquid into the drain. Sometimes users find that clothes remain wet after washing and spinning – this could also be the fault of the water level sensor.

The sensor measures the amount of water in the drum. If it malfunctions, the pressure switch begins transmitting incorrect information to the "brain." For example, it reports the drum is full when it's actually empty. Of course, in this case, the module won't prompt the washing machine to fill.

To check the pressure switch:

- turn off the power to the washing machine and disconnect it from the sewer system;

- Unscrew the screws holding the top panel of the washing machine housing and remove the cover;

- find the water level sensor;

- prepare a tube whose diameter will correspond to the pressure switch fitting;

- detach the pressure hose from the sensor and connect the prepared tube to this place;

- Blow gently into the tube; if you hear quiet clicks, the pressure switch is OK.

Immediately inspect the level sensor relay and housing. Be sure to clean the pressure hose; dust often accumulates there, which can cause the pressure switch to malfunction. It's a good idea to check the part with a multimeter.

Resistance is measured using the standard method. The multimeter probes are placed across the pressure switch relay contacts. The value on the tester screen should then change. If it remains the same, the level sensor will need to be replaced.

Removing a faulty pressure switch is easy. Disconnect the power supply wires and remove the mounting screws. Install the new level sensor, connecting the wires and pressure hose to it. After that, you can reassemble the housing and run a test wash.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Hello, the w65z02 Gorenje machine does not fill with water during washing, rinsing and pre-wash work.