Samsung Washing Machine Maintenance

Maintaining an automatic washing machine is a sensitive issue for many housewives. While preventative measures can significantly extend the life of the machine, they also waste time and money, especially if you need to call a technician. However, if you don't find the right balance and don't take proper care of your "home helper," it will only last a few years before suffering from clogged drains, black mold, limescale, and even breakdowns of key components. Therefore, it's definitely worth setting aside time for servicing your Samsung washing machine, especially since it doesn't require much maintenance.

Maintaining an automatic washing machine is a sensitive issue for many housewives. While preventative measures can significantly extend the life of the machine, they also waste time and money, especially if you need to call a technician. However, if you don't find the right balance and don't take proper care of your "home helper," it will only last a few years before suffering from clogged drains, black mold, limescale, and even breakdowns of key components. Therefore, it's definitely worth setting aside time for servicing your Samsung washing machine, especially since it doesn't require much maintenance.

Routine machine maintenance

The simplest rule, known to all washing machine owners, is to leave the machine open after the cycle to allow any remaining water to evaporate and to remove any unpleasant odors from the drum. It is also important to remember that washed clothes must be removed from the machine quickly to prevent mold from developing due to humidity in the device. Finally, you need to dry the hatch glass, powder receptacle, rubber seal and drum surface.

Everything listed in the previous paragraph should be done after every wash. As for deep maintenance of your "home helper," it's best to do it every 2-3 months. For this preventative maintenance, you'll need:

- turn off the machine from the power supply and also disconnect it from the water supply;

- remove the detergent drawer and then wash it with soap or another detergent in warm water;

It is important to remove plaque and traces of mold from the cuvette, so if these are present, cleaning should be more thorough.

- disconnect the inlet hose from the device, then remove the filter mesh to clean it under the tap and remove all scale and debris;

- Clean the drain filter, located in the lower right corner of the washing machine behind a separate panel. First, place a basin under the machine, line it with dry rags, and only then remove the plug to prevent water from spilling onto the floor. Once the water drains, remove the filter and thoroughly rinse it and the walls of the drain hole.

- Now you need to check the rubber seal on the drum. There shouldn't be any cracks in the rubber, and if there's dirt or mold, it should be carefully removed.

- Rotate the drum manually. It should rotate without any significant obstructions, but with a slight tension. It's crucial that there are no creaking or grinding sounds. If you detect any unusual noises, you'll need to call a technician for a professional appliance inspection.

- Finally, disconnect the drain hose and check the tube for blockages, which can be done by simply feeling it.

Thus, deep maintenance can be performed independently, without the help of specialists. It requires neither technical training nor special tools.

Non-standard service

However, sometimes situations arise when a cursory inspection won't reveal the problem. If your washing machine suddenly starts making loud noises, humming, vibrating during operation, or bouncing high, a more in-depth diagnosis is necessary. In this case, the Samsung washing machine will need to be disassembled to thoroughly inspect the dampers, bearing assembly, and counterweights. To do this, follow the instructions carefully.

- Disconnect the washing machine from the power supply, turn off the water supply, then disconnect the drain and inlet hoses from the body.

- Ensure access to the sides and back of the machine by moving it away from the wall. It's also a good idea to have a few dry rags ready.

- Now let's start disassembling the equipment - first, remove the top cover by unscrewing the fixing bolts.

- Repeat the procedure with the back wall, unscrewing the holding screws.

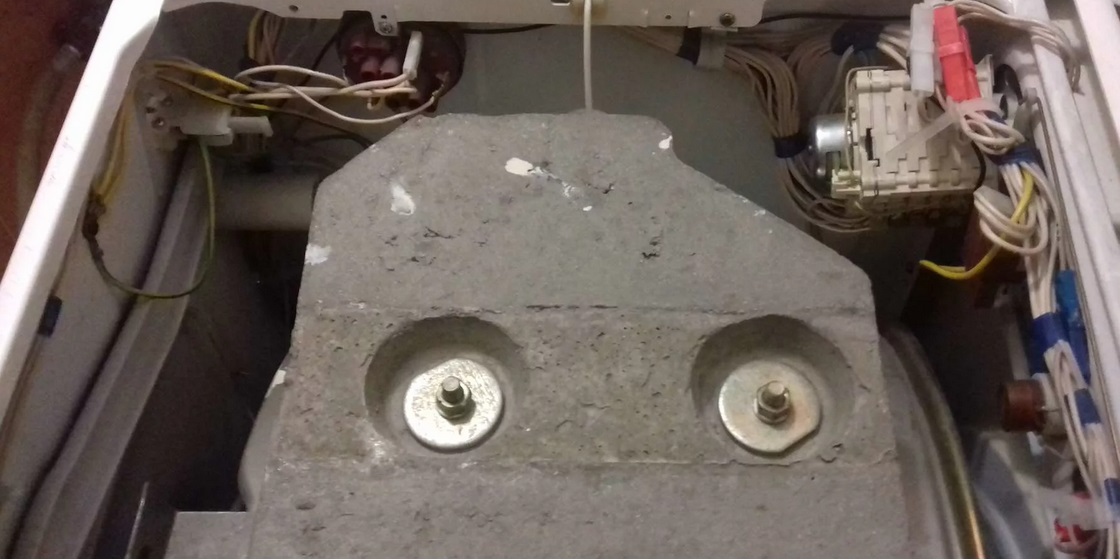

- Inspect the counterweights—the concrete blocks should be intact, without cracks or chips. You can also press down on the blocks to check if the bolts are tight. If not, tighten the fasteners, and if they are damaged, replace them.

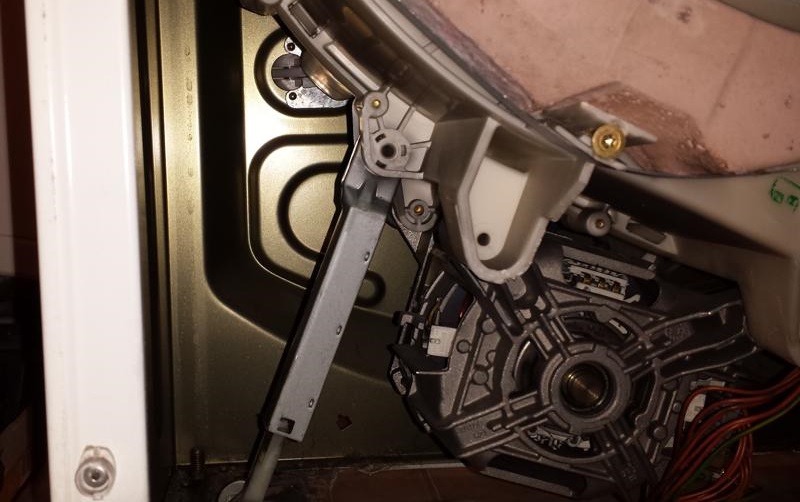

- Test the drive belt tension. The rubber band shouldn't slip, so if it does, either replace it or thoroughly wash it, dry it, and then rub it with pine rosin.

- Below, you need to check the shock absorbers—they should be elastic. While you're at it, lubricate the springs with graphite grease to prevent corrosion.

- Once you reach the heating element, disconnect its wiring, unscrew the nut and disconnect it for further manipulation. If it is completely covered in scale, it should either be replaced or soaked in a vinegar solution to soften the scale and make it easier to clean.

- Additionally, you can inspect all the sensors and wires of the machine, which should be replaced if defects are found.

- Finally, it's worth inspecting the tubes running from the dispenser to the tank, as well as the fill valve. All of these parts should be not only intact but also dry.

Be sure to take a photo of the wires connected to the washing machine components so that you have an example of how to properly reconnect everything.

It's important to remember that if your washer starts making loud grinding noises during washing, rattling during the spin cycle, or if the drum starts to wobble excessively, it's time to buy new bearings. At least once every few years, have it thoroughly checked to identify and fix any problems proactively. This can extend the life of your washer by several years, which is worth it.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment