Whirlpool washing machine error E06

Inexperienced technicians, upon detecting the E06 error on Whirlpool washing machines, resort to diagnosing the tachometer. Experience shows that such attempts are a waste of time. The tachometer in Whirlpool washing machines rarely fails. The tachometer may be dislodged or slightly misaligned, but this problem can also be detected by visual inspection. It's best to carefully test other components that are causing the E06 error.

Inexperienced technicians, upon detecting the E06 error on Whirlpool washing machines, resort to diagnosing the tachometer. Experience shows that such attempts are a waste of time. The tachometer in Whirlpool washing machines rarely fails. The tachometer may be dislodged or slightly misaligned, but this problem can also be detected by visual inspection. It's best to carefully test other components that are causing the E06 error.

What broke?

A literal interpretation of the E06 error code indicates that the tachometer is transmitting incorrect engine speed information to the washing machine's main control module. More precisely, the intelligent module is commanding the motor to accelerate to the desired speed, but the Hall sensor is reporting that the specified RPM cannot be reached.

The cause of the error isn't a broken tacho sensor (it accurately detects that the drum isn't spinning at the required speed). The problem should be looked for elsewhere to begin repairing the machine. Most often the error E06 indicates a stretched drive belt, a broken motor, or broken drum bearings.

First, you can check the drive belt tension and tighten it if necessary. If the belt drive is fine, it's a good idea to test the electric motor and bearings. The washing machine motor may be operating under increased load precisely because of damaged bearings.

Let's check the bearings

The main symptom of broken bearings is a loud noise emitted by the washing machine during washing. You can check the condition of the bearings without disassembling the washing machine. Grasp the rib inside the drum, apply gentle pressure, and rotate the drum, first clockwise, then counterclockwise.

A sign of bearing failure will be an intermittent, strained rotation of the drum, accompanied by a humming sound.

If the drum moves freely and the machine responds silently to your manipulations, the bearings are fine.

A damaged seal can cause bearing failure. The seal acts as a sealant, protecting the bearings from water ingress. When the seal is damaged, liquid leaks in and accelerates bearing wear.

You can confirm that the bearings are damaged by removing the back panel of your Whirlpool washing machine. If rusty stains are clearly visible on the drum, it's time to replace the seal and bearings. Water isn't the only thing that can ruin bearings; they often fail due to natural wear. In this case, instead of brown streaks, you'll see clearly visible oil stains from the grease on the drum.

Operating a washing machine with damaged bearings is prohibited, as this can cause much more serious damage to the bushing or shaft.

You can perform repairs yourself by replacing the bearings and seal. However, this is a very labor-intensive task and requires specific knowledge and skills. You need to understand the design of the washing machine, understand the bearing mounting pattern, and more. The work involves completely disassembling the washing machine, disconnecting the wiring, removing and disassembling the drum, removing the bearings and seal, installing new parts, and reassembling the appliance. If you have no experience repairing machines, it's best to entrust a major overhaul to a professional.

Testing the engine

What to do if the bearing diagnostics did not reveal any problems? Error E06 may indicate a failure of the Whirlpool washing machine's collector motor. You can test the motor yourself at home. Here's the procedure for testing an electric motor:

- de-energize the washing machine;

- remove the top cover of the case;

- unscrew the back panel (on some models – the front panel);

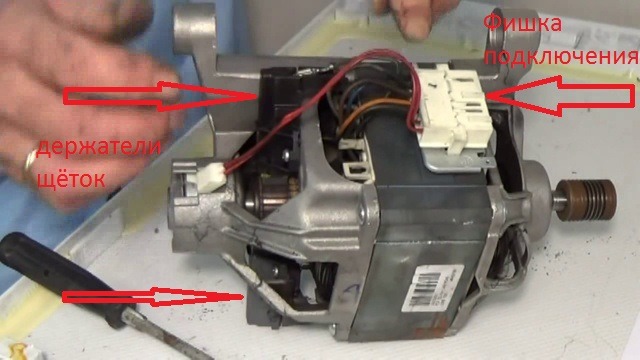

- find the engine, it is located under the washing machine tank, at the back, secured to the metal frame with screws;

- disconnect the terminals, disconnect the wiring, unscrew the mounting bolts and remove the engine from the housing;

- Connect the stator and rotor in series, apply 220 V voltage to the ends.

Voltage must be supplied through a ballast, which can be the heating element of a washing machine.

If the motor starts to rotate after being plugged in and the autotransformer doesn't overheat, the electric motor is operating normally. Most often, the washing machine's motor fails due to:

- breakdown of electric brushes;

- winding break;

- defect of collector lamellas.

Replacing the electrical brushes can help fix the problem. These are small graphite cubes that conduct current. When the equipment is running, the brushes rub against the commutator. It would be advisable to replace the electric brushes in the following cases: decreased rotation force of the drum or its stopping, unusual noise during operation of the washing machine.

Brush failure is most often caused by exceeding the drum's maximum load capacity. Components also wear out faster if the spin cycle is constantly run at maximum speed. Brushes also break due to a short circuit in the motor winding or a stretched or damaged drive belt.

Inspecting the components will help you determine when the brushes need replacing. If they spark during operation, or a black coating appears on the surface of the graphite cubes, the brushes need replacing. Replacement parts are inexpensive, and repairs are easily done yourself. Purchase suitable brushes from a specialized retailer or order them from a service center. Ideally, these are genuine parts from Whirlpool.

Replacement electric brushes must be fully compatible with the type of electric motor of the washing machine model.

Replacing the fins can help clear the fault code. They are what direct current through the rotor winding to the electric motor. Failure of the fins themselves is extremely rare; the cause may be loose winding contacts or delaminated fins.

If the slat delamination is minor, the problem can be repaired using a special machine by resurfacing the commutator. You can also do the repair yourself at home using fine sandpaper. The principle is the same: the slats are sharpened, and the space between the plates is cleared of debris and chips.

You can determine if the fins are the problem by spinning the rotor. If a characteristic sound is heard, the conductive fins are defective. Error E06 may be displayed if the electric motor is not operating correctly due to a break in the rotor or stator winding. A break in the rotor or stator winding causes a loss of motor power and stops operation. A break in the winding can occur:

- When the motor housing overheats due to short circuits in the winding. The optimal motor temperature is up to 80°C; when the temperature rises to 90°C, the thermostat is activated, blocking the motor.

- If the winding insulation is damaged. Repairing the motor yourself in this situation is not recommended. A service center should be called in. The entire Whirlpool washing machine motor can be replaced with a working one.

How can I detect a broken stator or rotor winding? Use a multimeter to measure the resistance between the motor fins. The standard value is 0.1-0.4 Ohm. Once you've diagnosed the problem, you should contact a professional to repair the winding or purchase a new electric motor as a replacement. A faulty washing machine motor is a fairly serious issue. If you're unsure of your ability to handle the repair, it's best to contact a service center immediately.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

The washing machine shown has a removable back cover, but mine does not have a back cover.