Siemens washing machine error E17

If your Siemens washing machine refuses to start a cycle and displays the E17 error code, there's a problem with the water fill. It's simple: the tank doesn't fill within the allotted 3-4 minutes, the pressure switch reports a problem to the circuit board, which, in turn, terminates the cycle. There's only one solution: find the cause of the problem and fix it. We'll explore what's preventing water from filling on your Siemens washing machine. We'll cover all the possible causes, along with diagnostic and repair instructions.

If your Siemens washing machine refuses to start a cycle and displays the E17 error code, there's a problem with the water fill. It's simple: the tank doesn't fill within the allotted 3-4 minutes, the pressure switch reports a problem to the circuit board, which, in turn, terminates the cycle. There's only one solution: find the cause of the problem and fix it. We'll explore what's preventing water from filling on your Siemens washing machine. We'll cover all the possible causes, along with diagnostic and repair instructions.

Water Purifying Mesh

Siemens often displays the E17 error code due to a clogged filter mesh. It's installed at the machine's inlet to reduce the negative impact of poor-quality tap water on the machine's internal components. As a result, most of the impurities contained in the water settle on the filter, leading to clogging and problematic filling.

The filter mesh is located in front of the inlet valve – in the hole where the inlet hose is connected. To clean the “inlet”, it is necessary to remove the filter and wash it thoroughly. Any Siemens user can handle this task. The key is to follow these steps:

- de-energize the machine and turn off the water supply;

- disconnect the inlet hose from the washing machine body by loosening the retaining clamp;

- drain the remaining water from the hose;

Be prepared! There will always be some water left in the inlet hose!

- find a mesh filter - a round attachment that covers the hole;

- Use pliers to grasp the protruding part of the filter;

- Without twisting, pull it towards you and remove the nozzle from the “socket”.

What to do next is clear: clean the mesh of accumulated dirt and deposits. Sometimes, rinsing the nozzle under the tap or scrubbing the "web" with an old toothbrush is enough. If the clog is severe, soak the filter for 30-60 minutes in a warm citric acid solution. Avoid using boiling water for cleaning, as the high temperatures will warp the plastic.

After finishing the wash, put everything back in place. Insert the filter into its "nest" using pliers, pressing it in as far as it will go, and secure the inlet hose. Then turn on the water and check for leaks at the connection. If all is well, plug it in and run a quick cycle on your Siemens washing machine. Did the E17 error disappear? Then the problem was a clogged nozzle.

Inlet valve

The inlet valve often causes water supply problems. It is responsible for starting and stopping the fill, receiving the appropriate command from the control board. If the valve malfunctions, the washing machine fails to fill within the allotted time and displays the E17 error code. To check the device's functionality, it must be tested in several stages.

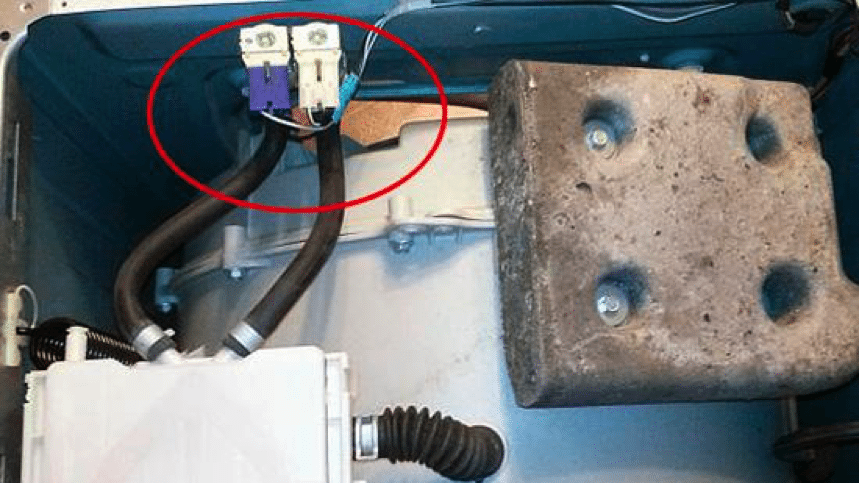

First, inspect the valve for external damage. Remove the top cover from the housing and locate the valve—it's located at the junction with the inlet hose and has several connected tubes. Then, assess its condition: are there any leaks, signs of fire, cracks, or other defects. If everything appears to be in good condition, proceed to disassembly.

- we loosen the fixing clamps and release the connected pipes;

- We take pictures of the valve terminals to make it easier to reconnect the wiring;

- we take the power wires away from the valve;

- unscrew the retaining bolts;

- we dismantle the device;

- We check if there are any blockages in the pipes.

Further diagnostics are best performed in the bathroom. Attach the inlet hose to the fitting and turn on the water supply. A properly functioning valve will control the flow of water and prevent leaks. If the appliance is leaking, repairs won't help—only replacement.

The next step requires vigilance and caution. 220 volts must be applied to the valve connected to the water supply. If all is well, the coil will close, the membrane will activate, and water will flow. Be careful, however, to avoid getting moisture on the wire contacts.

The washing machine valve is not repairable - if it breaks, it is replaced with a new one.

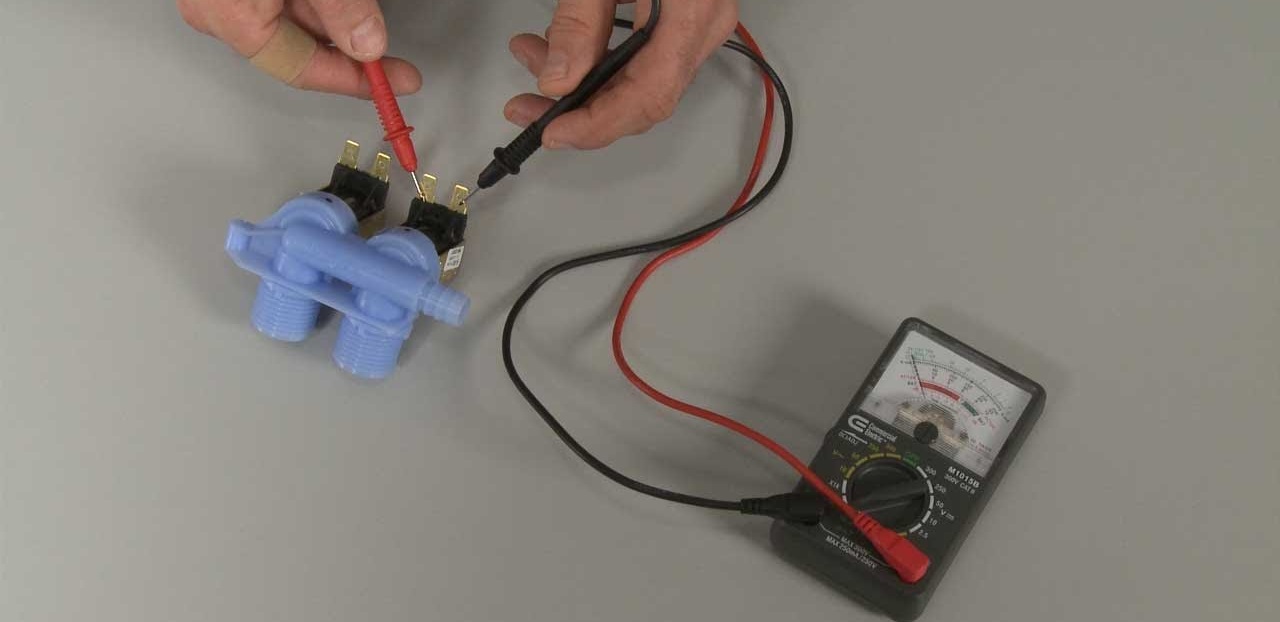

The final step in checking is a multimeter test. Set the tester to ohmmeter mode and alternately touch the probes to the solenoid valve coil. Normally, the resistance should be around 3 kOhm; if the device shows less, there's a problem. You can't repair the device yourself; you'll need to replace it with a working one. Install the new valve as follows:

- insert the coil into the seat;

- we fix the device with bolts;

- using the photo taken earlier as a guide, we connect the wiring and pipes;

- we return the top cover to the body.

All that's left to do is plug in the Siemens and run a test wash. If the error persists, we'll continue with the diagnostics.

Water level monitoring element

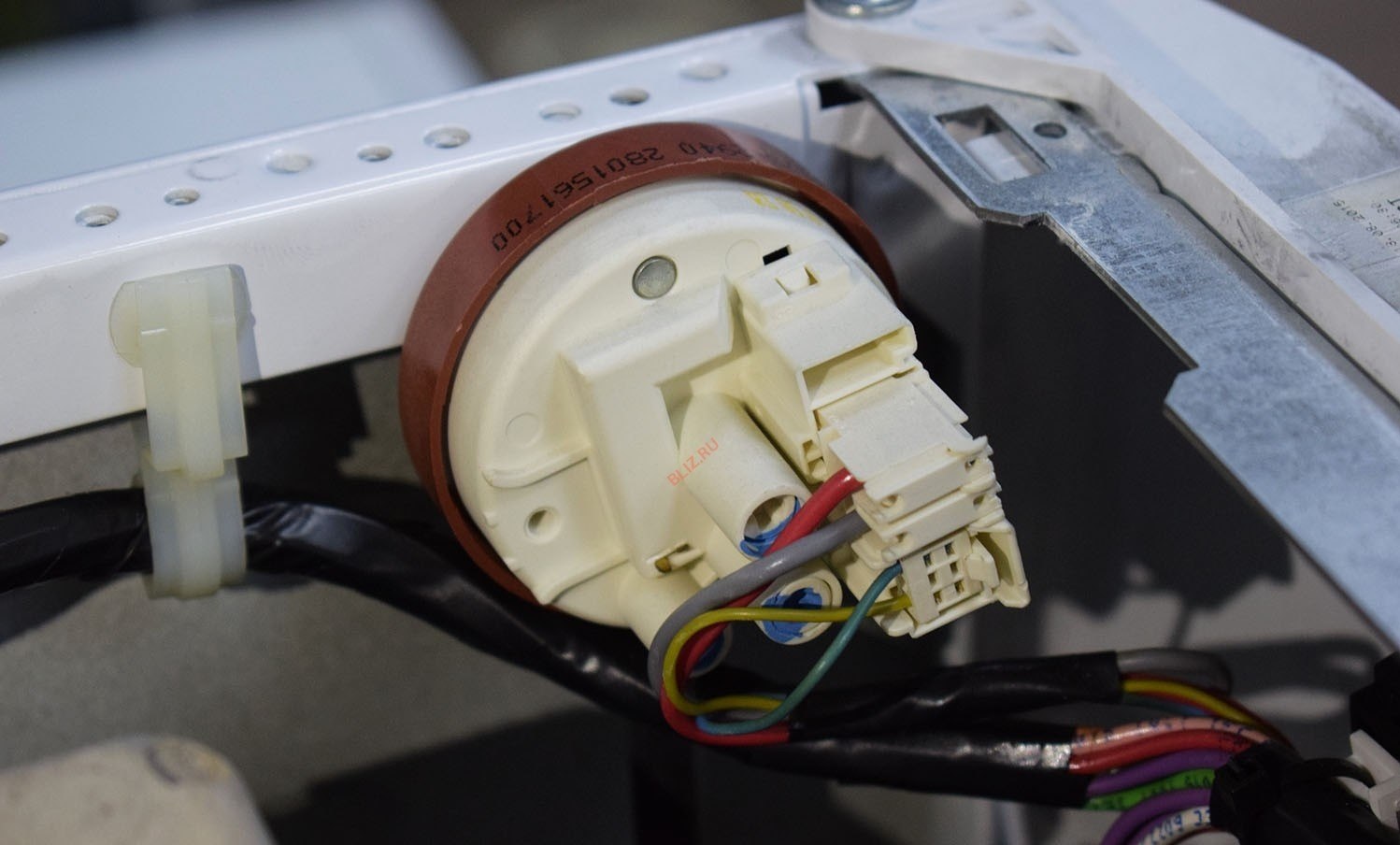

Next in line is the pressure switch. An incorrectly functioning level sensor may signal that the tank is full even before the filling process begins, sending a corresponding command to the board.Naturally, the module stops filling with water, and the Siemens washing machine remains empty. To reset the error and restore operation, you need to diagnose the pressure switch. Here's how:

- disconnect the washing machine from the power supply;

- turn off the water supply tap;

- remove the top cover by unscrewing the corresponding bolts from the back panel;

- near the side wall we find a pressure switch - a device with a tube lowered into the tank;

- we disconnect the pressure hose from the sensor;

- we take a tube proportionate to the diameter of the pressure switch fitting;

- We apply the found tube to the nozzle and lightly blow into it.

Next, listen carefully: a working pressure switch will respond to the air flow with 1-3 clicks, while a broken one will remain silent. Diagnostics continue with a visual inspection of the part. The sensor should be checked for defects, blockages, and mechanical damage. If any contamination is detected in the tube, the situation can be corrected by clearing the hose under the tap.

When replacing components on Siemens, you must select only original spare parts that match the model by serial number.

It's better to go beyond a visual inspection and test the sensor with a multimeter. First, study the pressure switch's electrical circuit and find the terminals suitable for diagnostics. Then, set the tester to buzzer mode and apply the probes to the relay contacts. Normally, the resistance reading should jump when the contacts are triggered. A static reading will indicate a fault.

It is impossible to repair a pressure switch at home; it is easier and cheaper to replace it. Finding a new water level sensor won't be a problem: just tell the seller the serial number of your Siemens washing machine.The cost of the device ranges from $5 to $25.

The new valve is installed in place of the old one and secured with bolts. The tube and previously removed wires are connected to it. Afterwards, replace the top cover, restore the water and power supply, and run a test wash. If the E17 error disappears and the machine fills, the problem is resolved. A repeated E17 error when starting a wash indicates a different problem. It's best to avoid experimenting and contact a service center.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment