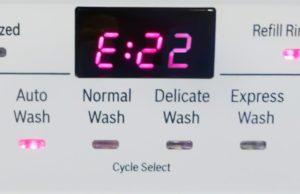

Error E22 in a Hansa washing machine

An unexpected E22 error message on the washing machine's display will inevitably raise a host of questions for the user. What's wrong with the machine, what should be done, and what does the code indicate? In most cases, it indicates a temporary system failure. Simply unplug the machine and wait 15-20 minutes before restarting. However, if the E22 error continues to appear, there's a problem with the Hansa washing machine that needs to be fixed. Let's find out together what exactly it is.

An unexpected E22 error message on the washing machine's display will inevitably raise a host of questions for the user. What's wrong with the machine, what should be done, and what does the code indicate? In most cases, it indicates a temporary system failure. Simply unplug the machine and wait 15-20 minutes before restarting. However, if the E22 error continues to appear, there's a problem with the Hansa washing machine that needs to be fixed. Let's find out together what exactly it is.

What happened to the car?

The error code generated by the washing machine limits the range of possible malfunctions. The alphanumeric combination displayed on the screen allows the user to independently determine the cause of the malfunction. Error E22 indicates a problem with the washing machine motor. In other words, it's the engine that's failed, not the wiring, the tachometer, or any other components of the automatic transmission. Very rarely, this code appears when the main control board's triac fails, but such cases are rare. So, what should you do if this error occurs?

- Check the washing machine motor for breakdowns.

- If the unit is equipped with a belt-driven electric motor, inspect the condition of the brushes. If they have recently been replaced, check to see if they are installed correctly.

- Inspect the manifold, it may need cleaning.

In this case, it is possible to fix the problem yourself, without resorting to the help of specialists. To carry out repairs yourself, you need to understand the root cause of the error. E22.

Detailed engine check

Hansa automatic washing machines are equipped with brushed motors, which pose some operating challenges. These motors are prone to broken fins and brushes, and the windings occasionally break down. As you can see, there are many possible causes for motor failure. But to understand what's wrong with the motor, you need to get to it:

Hansa automatic washing machines are equipped with brushed motors, which pose some operating challenges. These motors are prone to broken fins and brushes, and the windings occasionally break down. As you can see, there are many possible causes for motor failure. But to understand what's wrong with the motor, you need to get to it:

- detach the back wall of the washing machine;

- carefully disconnect the wiring from the motor;

- Unscrew the mounting bolts and remove the engine from the housing.

Once you have the part in hand, begin diagnosing the engine. Connect the stator and rotor winding wires together. Next, connect the created connection to a 220V power source. If the rotor rotates, the device is functioning properly. However, this diagnostic method has its drawbacks:

- It is impossible to completely confirm the engine’s functionality, especially its operation in various washing modes;

- When connecting the engine directly to the network, there is a possibility that it may simply short-circuit.

Therefore, it's best to add a ballast to the circuit being created to protect the motor. A heating element from a circuit breaker works well for this. Connect the components using the following diagram as a reference:

By securing the winding wires in this manner, you ensure the motor's safety. When a short circuit occurs, the heating element will heat up, protecting the motor from burning out. By examining the structure of the commutator motor, you can see that it has several components. To determine what is causing the error code, all components should be checked.

- Electric brushes. They are located on the sides of the motor. Inspect them; if any are worn, replace them. It's easy to tell if the problem lies with the brushes. Connect the motor wiring to the power supply; if the engine sparks, the problem is with the brushes. You can purchase replacement brushes at a specialty store by telling the manager your washing machine model.

- Lamels. These components conduct electricity to the rotor. Lamels are attached to the shaft with glue, so they tend to peel off. Small peelings can be removed using a lathe (by carefully turning the commutators). When inspecting the lamellas, pay attention to any peeling, as this will indicate a problem with the motor.

- Rotor and stator winding. If problems arise with the winding, the washing machine motor will not be able to operate at full power or will fail altogether. When a short circuit occurs, the motor overheats. The thermistor automatically shuts off the motor for safety. To diagnose the winding, you'll need a multimeter. Switch the device to resistance mode, and place the multimeter probes against the fins. Normally, the display should show a reading between 20 and 200 ohms.

If the resistance value does not reach the normal limits, a short circuit occurs; if it exceeds them, a winding break can be detected.

The starter should also be checked with a multimeter. Select the buzzer mode and apply the probes to the wires one by one. If the tester is silent, everything is fine. If the device makes a sound, look for a short circuit by applying one probe to the body of the component and the other to the wiring.

Once the defect is identified, it should be repaired. If the brushes are the issue, replace them; the lamellas may need to be treated. Trying to repair the winding is not worth it; it's better to buy a new motor.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment