Error E51 in Electrolux washing machine

An Electrolux washing machine, which has served reliably for many years, suddenly stops working and displays the E51 error code. Most technicians would immediately assume the problem lies with the control module and begin updating the firmware or searching for faulty triacs. However, these steps are premature. In 80% of cases, the E51 error code in Electrolux washing machines is caused by a defective motor, so it's recommended to diagnose the motor first.

An Electrolux washing machine, which has served reliably for many years, suddenly stops working and displays the E51 error code. Most technicians would immediately assume the problem lies with the control module and begin updating the firmware or searching for faulty triacs. However, these steps are premature. In 80% of cases, the E51 error code in Electrolux washing machines is caused by a defective motor, so it's recommended to diagnose the motor first.

We'll pull it out and do a general check of the engine.

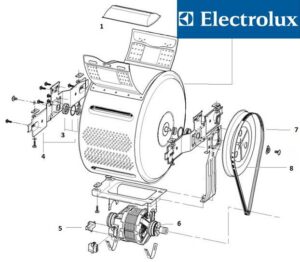

To troubleshoot a faulty washing machine, you need to understand the structure of the washing machine's electric motor. The Electrolux brushed motor can be tested and repaired even at home. Its main feature is high power in a relatively compact size. A drive belt transmits torque from the motor to the drum.

The motor itself consists of a stator, a rotor, and a pair of electric brushes. A special sensor located on top monitors the rotation speed. When the error code E51 specialists diagnose problems using different methods, but the work always begins with removing the engine. The sequence of actions is the same in all cases and does not depend on the specific model. We will describe the process.

The motor itself consists of a stator, a rotor, and a pair of electric brushes. A special sensor located on top monitors the rotation speed. When the error code E51 specialists diagnose problems using different methods, but the work always begins with removing the engine. The sequence of actions is the same in all cases and does not depend on the specific model. We will describe the process.

- Unscrew the bolts from the back wall and remove it.

- Loosen and then remove the drive belt. To do this, rotate the drum pulley. Be careful not to pinch your fingers.

- Disconnect the ground and power wires going to the motor.

- Unscrew the bolts that secure the engine to the mounting points.

- Carefully remove the electric motor, rocking it from side to side.

Important! If this is your first time repairing an engine, take a photo of the wiring beforehand—this will allow you to easily reinstall the part.

What to do next? The simplest way to diagnose a motor is to connect the wires from the rotor and stator windings, then apply 220 volts (mains voltage) to them. Rotating the shaft means the motor is working. However, this approach doesn't reveal all hidden defects associated with the E51 error code, and they may become apparent during actual operation. Furthermore, a direct connection can have adverse effects on the motor.

Therefore, an additional ballast—a heating element from a circuit breaker—is usually installed in the circuit. If a short circuit occurs in the electric motor windings, the heating element will heat up, absorbing the full impact. The next step in checking is the brushes.

Brushes and graphite dust

Worn-out brushes are a common cause of error code E51. The brushes are located on both sides of the motor and cushion the friction generated by it. The carbon tips are the ones that wear out most. To check them, follow these steps:

Worn-out brushes are a common cause of error code E51. The brushes are located on both sides of the motor and cushion the friction generated by it. The carbon tips are the ones that wear out most. To check them, follow these steps:

- unscrew the mounting bolts;

- compress the spring and remove the electric brushes;

- disassemble each brush;

- Measure the tips - if the length is less than 1.5 cm, they must be replaced.

Always replace the brushes together, even if one appears new. It's ideal to purchase genuine parts, as replacement brushes from other motors have different sizes and shapes and will require additional machining. Installation follows the instructions above, in reverse order. The installation site must first be cleaned of graphite dust. There are situations when it is the abundance of dust that causes the E51 error code to appear.

Other elements

Commutator lamellas are responsible for transmitting electric current to the rotor. Lamels are copper or alloy contacts that are directly attached to the shaft. They can peel off and fail when the motor seizes (or due to interturn short circuits in the windings). Damaged contacts have burrs and delaminations.

Important! If the damage is minor, it can be repaired with sandpaper and a lathe.

Engine starting and acceleration are also disrupted if the winding is damaged. A short circuit occurs, and the electric motor overheats. The temperature sensor detects the high temperature and goes into emergency mode, shutting down the system. This vicious cycle can only be broken by fixing the problem; otherwise, it will repeat itself over and over again until the thermistor fails. The winding quality is checked with a multimeter:

Engine starting and acceleration are also disrupted if the winding is damaged. A short circuit occurs, and the electric motor overheats. The temperature sensor detects the high temperature and goes into emergency mode, shutting down the system. This vicious cycle can only be broken by fixing the problem; otherwise, it will repeat itself over and over again until the thermistor fails. The winding quality is checked with a multimeter:

- On the device, turn on the “Resistance” mode;

- the probes are applied to the contact lamellas;

- The normal resistance value is 20-200 Ohms. If the display shows more, then the problem is an open circuit; if it shows less, then the problem is a short circuit.

A multimeter is also used to diagnose the stator. To do this, turn on the buzzer mode and apply the probes to the winding one by one. If the tester doesn't respond, everything is working properly. If damage is detected, don't rush to repair the electric motor yourself. It's too expensive; it's much easier to buy a new motor.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment