Error E60 in a Midea washing machine

It's logical that the more modern a household appliance, the more advanced components it contains, which can fail during use. The E60 error in a Midea washing machine is one of the most common problems with this brand's washing machines, and it's related to the appliance's electric motor. If you see this code on your washing machine's display, the malfunction is most likely caused by damaged motor brushes, although it's also worth checking the tachometer, winding, and fins. Let's look at how to properly remove the electric motor and conduct a full diagnosis.

It's logical that the more modern a household appliance, the more advanced components it contains, which can fail during use. The E60 error in a Midea washing machine is one of the most common problems with this brand's washing machines, and it's related to the appliance's electric motor. If you see this code on your washing machine's display, the malfunction is most likely caused by damaged motor brushes, although it's also worth checking the tachometer, winding, and fins. Let's look at how to properly remove the electric motor and conduct a full diagnosis.

We extract the engine

The first stage is preparation for repair, because first you need to gain access to the engine, and only then study it. Carefully prepare the appliance for dismantling. To do this, disconnect it from the electricity and water supply, and then move it away from the wall so that nothing interferes with removing the rear panel of the washing machine. Let's start disassembling household appliances.

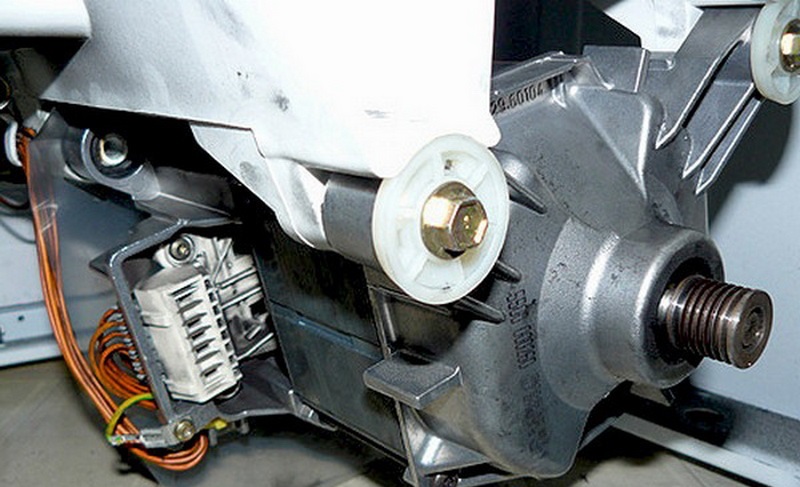

- Using a hex screwdriver, remove the back panel of the machine.

- Remove the drive belt from the pulley.

- Disconnect all wiring from the electric motor.

It's best to take a photo of the correct wiring connections to the electrical unit so you have a reference when reassembling.

- Remove the screws that hold the motor in place.

- Remove the electric motor by rocking it in different directions.

For the next stage of work, you will need almost the same set of tools that were used now - Phillips and flat-head screwdrivers, a phone to take photos, plus a multimeter to check the functionality of the key components of the SM.

Carbon brushes

The first thing you should check yourself when the E60 error code appears is the carbon brushes, which are the most common cause of failure. They are located on the sides of the motor housing and have a wire that supplies power, as well as a spring that pushes them forward and presses them against the fins. The brushes need to be removed and carefully inspected - if they are worn out and have become 1 centimeter long or even less, then they need to be replaced. To replace the parts, you first need to remove the worn carbon elements. What should you do?

- Using a flat-head screwdriver, carefully pry up the power cable terminal and pull it off.

- Take the brush contact and slide it away from the wire.

- Gently pull the contact upwards so that the brush, under the influence of the spring, pops up on its own.

Record in your memory or in a photo exactly how the brush was positioned, so that later you can put it back on the correct side.

- Check the old elements to see if they are really worn out and need to be replaced.

- If replacement is necessary, it is worth purchasing exactly the same parts that are suitable for Midea equipment, and then installing them in the same way as the previous brushes were installed.

- Next, you need to place the spring, which should be carefully compressed so that it fits completely into its seat.

- Now insert the terminals into the clamps and slide them towards the power wire to secure the motor carbon brush.

- Place the connector with the wire onto the carbon brush terminal and proceed to replacing the second brush of the washing machine.

Brushes should always be replaced in pairs, even if only one element is damaged, as this can prolong the life of the electric motor. Once repaired, all that remains is to test all contacts with a multimeter and run a test wash to evaluate the work done.

Let's check the winding

Error code E60 may also appear due to damage to the winding. This is due to the fact that short circuits occur in the wire coils, causing the motor to overheat, activating the thermistor, and the Midea washing machine's control board to urgently shut off power to the entire system. This situation will repeat until either the temperature sensor or the electric motor itself burns out. To prevent this from happening, check the winding with a multimeter as follows:

- switch the multimeter to the resistance measurement program;

- connect the tester probes to the lamellas;

- evaluate the obtained value, which should be between 0.1 and 0.4 ohms.

If something is wrong, don't try to repair the winding at home. You should seek help from a service center specialist, or simply buy a new electric motor and install it in its place.

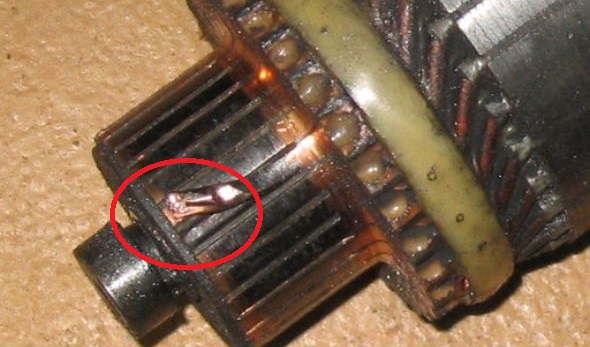

Something happened to the slats

If the motor fails due to loss of contact with the rotor winding, the cause is either the fins or the wire located near the fins. This could occur because the current supplied to the motor is unable to reach the rotor, or its strength is not sufficient, which poses a risk of short-circuiting or even burnout.

Home appliance manufacturers create special hooks when connecting winding sections, which improve contact. Unfortunately, wires sometimes break during operation because they catch on various protrusions. To fix this, you'll need to improve the circuit's integrity.

It is not recommended to use an electric motor with detached slats, as this may cause an emergency.

Restoring the machine's functionality is even more difficult if the fins have peeled off due to excessive heat, which could occur after a short circuit or rotor spin. This occurs because the fins have been subjected to a current that exceeds the maximum permissible value, causing the thin metal to overheat and peel off. This most often occurs in the following situations:

- the bearings of the "home assistant" are faulty, so they suddenly "stop" the electric motor;

- The cycle was started with the drum doors not locked in place in a top loading washing machine, causing the machine to stop suddenly.

Slats never fail without a reason, so peeling indicates either improper use of the Midea washing machine or a faulty motor. This is why both appliance repair and a change in habits are necessary.

When the lamellas have peeled off by just 0.5 millimeters or less, the shaft only needs to be resurfaced. To do this, locate all protruding elements, carefully remove them, and then remove any remaining roughness, unevenness, dust, and other possible contaminants.

It's easy to verify that the fins have indeed detached. Simply spin the rotor gently and listen for the sound. If you hear a loud cracking sound, the fins are catching the winding.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment