Error E8 in a Daewoo washing machine

If your Daewoo washing machine displays "Error E8," a thorough diagnostic is required. Troubleshooting is complicated by the fact that several system components, from the tachogenerator and motor to the control board, can cause this error code. To isolate the problem, you'll need to check all possible culprits one by one. This is difficult to do without professional help, but it's possible if you follow our instructions.

If your Daewoo washing machine displays "Error E8," a thorough diagnostic is required. Troubleshooting is complicated by the fact that several system components, from the tachogenerator and motor to the control board, can cause this error code. To isolate the problem, you'll need to check all possible culprits one by one. This is difficult to do without professional help, but it's possible if you follow our instructions.

What does this code mean?

The E8 error can appear on both top-loading and front-loading Daewoo washing machines. The year of manufacture doesn't matter: both modern and older machines are at risk. As for the source of the problem, the manufacturer provides the following explanation of the code:

- failure of the tachogenerator, which is responsible for regulating engine speed (also called the Hall sensor);

- control module malfunction (more precisely, burnout of one of the board elements, most often the motor control triac);

- engine failure.

Self-diagnosis and repair of the control board is not recommended, as this requires extreme care, special knowledge and equipment.

A more accurate diagnosis can be made by inspecting the machine while it's running. For example, if the washing machine drum isn't accelerating to the set speed, is spinning slowly, or even stalls mid-cycle, check the motor first. Conversely, if the machine accelerates excessively or constantly jumps from minimum to maximum, it's worth checking the Hall sensor. But most often, a faulty board makes itself known, so it is better to first diagnose the control module.

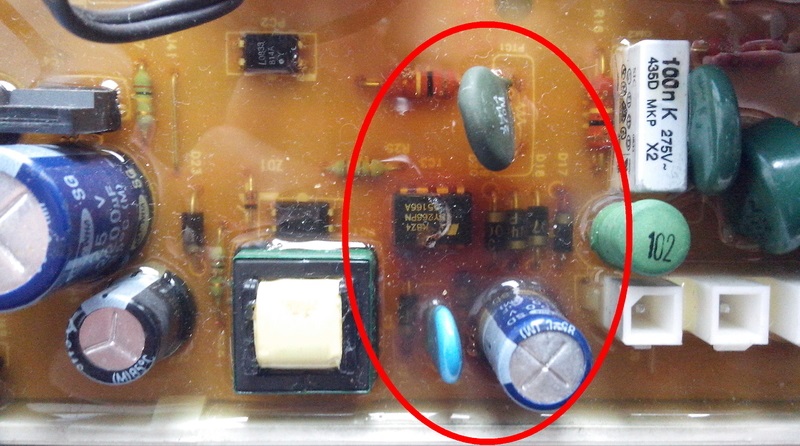

Testing the control board components

So, you've decided to repair the control board yourself. Then you'll have to figure out which component on the module responsible for the motor's operation has failed. To avoid guesswork and experimentation, it's best to use a diagram of the electronic unit. It's usually included in the washing machine's manufacturer's manual.

Mechanical damage to the board, burnt contacts and disconnected electrodes are visible to the naked eye.

Next, we disassemble the top of the machine and carefully remove the circuit board. Before testing with a multimeter, inspect the module from both sides, looking for obvious scratches, chips, loose contacts, burnt tracks, or broken electrodes. If such damage is present, a comprehensive diagnosis is not necessary—it's only necessary to fix the problem. Once everything appears to be in good condition, it's time to inspect the board components one by one.

- Capacitor. A burnt-out capacitor is a common cause of the E8 error. In washing machine units, it acts as a stabilizer and absorbs voltage surges. A burnt-out capacitor cannot be repaired; the circuit board must be removed, a similar one must be found, and soldered in place using a lamp. Installing additional filters can reduce the risk of re-ignition. However, keep in mind that the condensate drain should only be connected to the positive electrode on the circuit board, and a multimeter is used to check the circuit's resistance.

- Resistors. The most common cause of board burnout is sensitive resistors. To correct this, test the module by measuring its resistance with a multimeter. First, connect the probes to the first line, where the value should be close to 8 ohms, and the overload indicator less than 2 A. Next, test the second line, where the overload is limited to 3-5 A. The final resistance depends on the unit's frequency; for example, in a simple circuit, the value will not exceed 10 ohms. If any deviations from the norm are detected, the components must be resoldered. Professionals also recommend replacing the filters.

- Thyristor unit. It fails if the network is overloaded beyond 220 V or there is impulsive interference. In this case, repairing it yourself will be difficult, but not impossible. First, measure the negative resistance of the board; it shouldn't exceed 20 V on the first-order diodes. Output contacts rarely burn out, but they also need to be checked. Take a tester, clean the cathode, and evaluate the readings. If the average value fluctuates around 12 V, the test is passed. Otherwise, replace the faulty filter. Purchase a new element and solder it through the positive contact to the thyristor unit. The main thing is to monitor the condition of the fragile but expensive ports and thoroughly clean the module after completing the work.

- Trigger. It breaks due to capacitor failure. Diagnostics are performed using a multimeter connected to the output contacts and a nearby filter. If the first reading on the tester is approximately 12V and the second is around 20V, then everything is fine. Otherwise, it will need to be repaired, which is quite time-consuming. First, solder the output valves, then install a new trigger, and measure the threshold voltage and resistance on the modulator. It's important to be careful with the capacitor cathode (it's easy to touch and damage when soldering the "neighbor").

These are the main “weak spots” on the control board that can lead to the display of the E8 error code. You can check and repair them yourself, but only if you have experience and practical knowledge. If module diagnostics fail to detect the problem, then we turn our attention to the engine and tachogenerator.

Checking and replacing the tachometer sensor

If the control board is OK, then we look for the problem inside the washing machine – on the motor. Error E8 indicates a problem with the tachogenerator. To check the sensor and replace it if necessary, follow these steps.

When disassembling a washing machine, remember safety rules: disconnect the machine from the power supply, water supply, and sewerage system.

- Disassemble the machine. Disconnect it from the power supply and utilities, unscrew the bolts holding the rear panel in place, and remove it. Next, release the drive belt by pulling on the rubber while simultaneously turning the pulley.

- Remove the motor. Use a camera to pinpoint the location of the wires, unscrew the motor mounting bolts, and, rocking the motor back and forth, remove the part from the housing.

- Inspect the tachogenerator. First, check to see if the contacts have come loose or the fasteners have become loose. This type of damage is easily fixed: simply restore the connections or tighten the fasteners.

- Check the resistance. There are two ways to check. The first is to measure the resistance with a tester by loosening the connectors and moving them away from the sensor. Normally, the contacts show approximately 60-70 ohms. The second option involves measuring with a tester in voltage mode, where the probes are applied while the motor is cranking. When operating, the readings fluctuate constantly within 0.2 volts.

- Assess the condition of the wiring. The tachometer sensor itself rarely fails, so inspect the integrity of the wires.

- Replace the Hall sensor. If a breakdown is detected, the faulty tachogenerator must be removed and a new one installed.

After the repair, run the cycle and see if the E8 error has disappeared.

If both the tachogenerator and the board are working properly, the motor is likely faulty. It's best to contact a mechanic for this problem, who will advise you on what to do and in what order.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Worn-out brushes are a very common reason why the engine won't turn...