My Daewoo washing machine displays error code E9.

Modern Daewoo washing machines are capable of automatically detecting and diagnosing problems thanks to a built-in self-diagnostic system. The machine detects a malfunction and notifies the user via the display—a code combination is displayed on the screen. All that's left to do is open the manual and decipher the "message." The machine often displays an E9 error, which indicates a malfunction in the pressure switch. The water level sensor should be checked and, if necessary, cleaned or replaced.

Modern Daewoo washing machines are capable of automatically detecting and diagnosing problems thanks to a built-in self-diagnostic system. The machine detects a malfunction and notifies the user via the display—a code combination is displayed on the screen. All that's left to do is open the manual and decipher the "message." The machine often displays an E9 error, which indicates a malfunction in the pressure switch. The water level sensor should be checked and, if necessary, cleaned or replaced.

Is the level sensor really broken?

According to the manual, the E9 error message indicates a problem with the pressure switch. However, this isn't always the case – Daewoo washing machines are equipped with fairly reliable and high-quality pressure sensors. These devices rarely break down, and more often, problems arise with their contacts. The pressure switch contacts on Daewoo washing machines, like those on many modern washing machines, are made of sensitive metal and oxidize with prolonged use in high-humidity conditions. Eventually, the sensor loses connection with the circuit board, and the system displays the E9 error.

Error code E9 on Daewoo automatic transmissions indicates problems with the level sensor!

It's best to check the version with oxidized contacts first. Here's what to do:

- remove the top cover from the machine body;

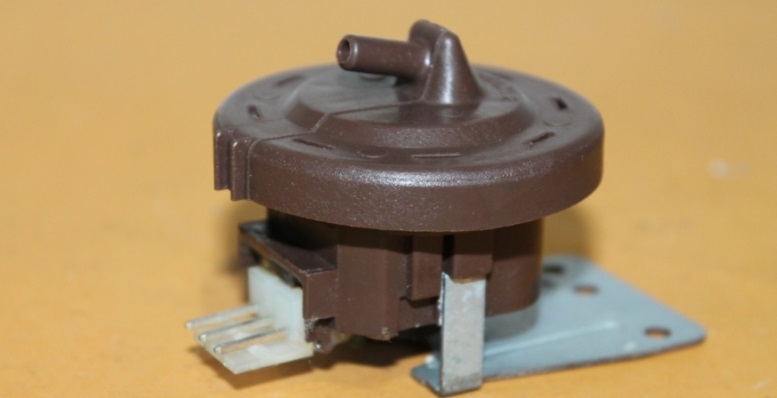

- find the pressure switch – a plastic “box” on the right wall;

- loosen the clamp securing the tube;

- disconnect the connector with the wiring;

- remove the sensor from its mounting location;

- clean the contacts with a sharp blade.

If cleaning doesn't help, or the contacts were clean from the start, your Daewoo washing machine is displaying the E9 code due to a faulty pressure switch. In this case, you'll need to continue the diagnosis by thoroughly inspecting the sensor and testing its continuity.

We carefully check the part

Diagnosis of the pressure switch begins with inspection. Sometimes the cause of sensor failure lies in its tube: it becomes clogged or damaged, and the device stops responding to pressure. In this case, it is easy to notice the breakdown – cracks and dust in the hose will indicate this.

If everything appears to be in order, we move on to checking the pressure sensor. Take a tube that's the same size as the fitting, attach it to the pressure switch, and gently blow. Do you hear a few clicks? Then the contacts are closed, and the device is working properly. "Silence" means the relay is broken and needs to be replaced.

The pressure switch fails due to blockage, damage or natural wear and tear.

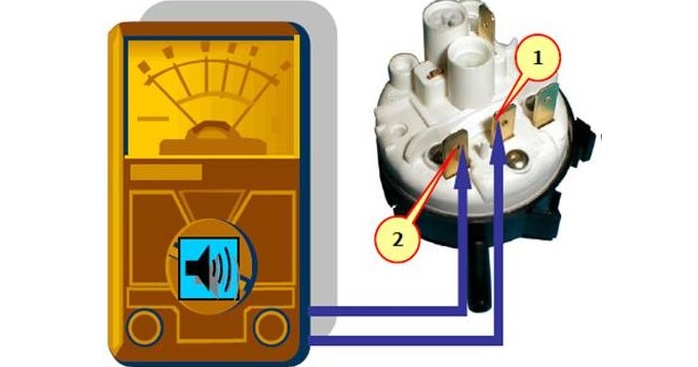

The next step is to test the circuit with a multimeter. Here's how:

- Let's understand the electrical circuit of the pressure switch;

- We mark which contacts the tester can be connected to;

- turn on the multimeter to “Ohmmeter”;

- we apply the probes;

- blow into the tube;

- We evaluate the value on the scoreboard.

Normally, "blowing" the pressure switch should change the initial reading on the multimeter. If the reading remains the same, the sensor is broken. It can't be repaired; it must be replaced with a new one.

Let's change the pressure switch

Most often, the only way to reset the E9 error is by replacing the pressure switch. It is not possible to repair the sensor, and it is not recommended: it is easier and cheaper to buy a new oneIts cost varies around $10. The main thing to consider when purchasing is the Daewoo serial number. You don't need to call a specialist to replace the sensor. You can perform the repair yourself using the following instructions:

- disconnect the machine from communications;

- find the pressure switch and disconnect the wires connected to it;

- loosen the retaining fasteners and clamps;

Before dismantling the pressure switch, take a photo of its initial position to avoid making a mistake when reconnecting the wiring!

- remove the faulty sensor;

- install a new pressure switch into the “nest”;

- secure the relay with screws and clamps;

- connect the wiring.

After replacing the pressure switch, reassemble the machine and run a test wash. Select any quick program and wait for the water to fill. If the drum fills, the cycle begins, and the display doesn't show the E9 error, then everything was done correctly. If the error persists even after installing the new pressure switch, the problem persists. It's possible the problem is electronic, with a fault on the control board. In this case, it's best to avoid attempting diagnostics and repairs yourself and contact a service center.

Interesting:

2 reader comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

If you've changed the brushes on the engine, you need to rub them in. The error occurs when the engine revs up. We rub the brushes in with sandpaper and everything works fine 🙂

Thanks, Bro.

You just can't imagine how much you helped out.

I would never have guessed.

Without removing the engine, I simply ran the spin cycle about 20 times and they rubbed in.

At first, an error popped up right away, then at 7, 6, 5, etc. minutes, and soon everything was fine.