Error F13 in a Whirlpool washing machine

When your Whirlpool washing machine displays "F13," don't panic and don't call a service technician. Even a novice can fix this error; the key is to decipher the signal pattern and follow the manufacturer's instructions. We'll explain the requirements and procedures in detail.

When your Whirlpool washing machine displays "F13," don't panic and don't call a service technician. Even a novice can fix this error; the key is to decipher the signal pattern and follow the manufacturer's instructions. We'll explain the requirements and procedures in detail.

What does this code mean?

Error F13 does not indicate any serious problems. According to the instructions, the combination is deciphered as “malfunction in the water filling system”In simple terms, the machine can't fill the drum to the required level. There's no water supply, or the machine takes too long to "think"—the system can't complete the command within the allotted time, and the board shuts down to prevent overflow. This failure can occur for three reasons:

- the central water supply is turned off or the existing pressure is too low;

- the water supply tap to the washing machine is turned off;

- the powder receptacle or the pipe leading to it is clogged;

- the inlet valve is out of order;

- The control board is frozen or burned out.

Control board failures are rare, so it's best not to rush into calling a repairman. Error F13 is more often displayed due to a clogged detergent drawer or a faulty inlet valve. In these cases, repairs take a few minutes to clean or replace components.

But first, it's important to rule out non-emergency causes of the failure. It's likely that the main water supply in the house is turned off, or the water supply valve is turned off. Confirming this is easy: just check other rooms and the shutoff valve. If all is clear, we can begin diagnosing the Whirlpool washing machine's filling system.

Testing the fill valve

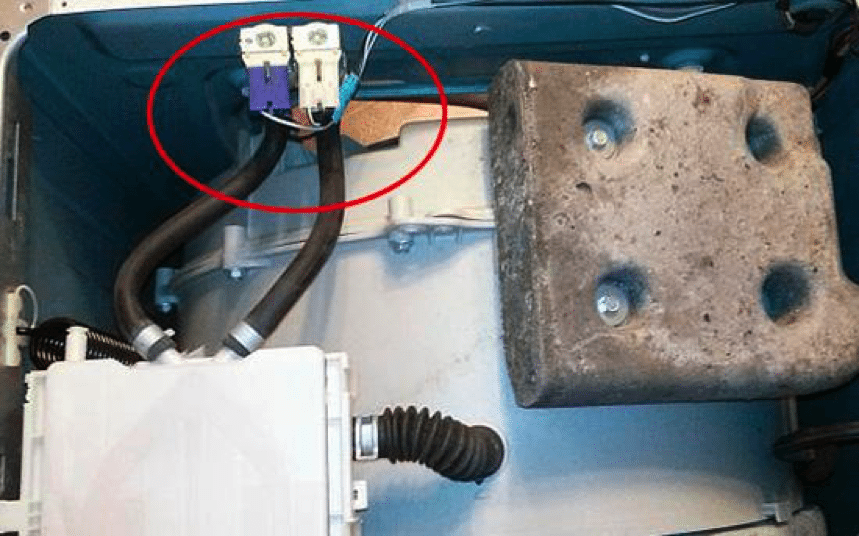

When the "F13" error appears, there's no need to ponder what to do. There's only one way: check all the components of the filling system, from the inlet valve and powder receptacle to the control board. It's best to start with the valve assembly, which is most often the cause of the error. Here's how to proceed:

- disconnect the washing machine from the power supply;

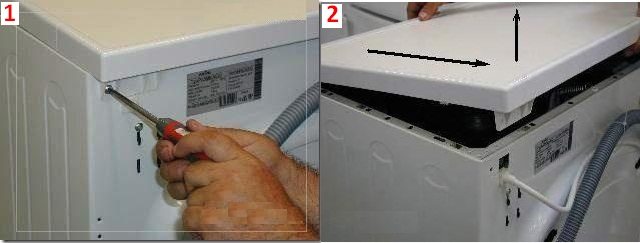

- remove the top cover from the case (unscrew the retaining screws from the back wall, lift the “top” and move it towards you);

- we find the fill valve at the junction of the hose and the body;

- We loosen the bolts that secure the device and remove the valve from the machine.

To diagnose the valve, connect the inlet hose to the device and apply 220V power to all available coils. If you hear a distinctive click and water flows, the membrane is working and the device is functioning properly. Otherwise, a more detailed inspection is warranted.

When performing the diagnostics described above, extreme caution is essential. First, avoid allowing moisture to come into contact with live wires. Second, it's important to have a suitable container for collecting the water. A valve that doesn't operate under voltage is faulty. More precisely, one of the coils has burned out. Confirming this "diagnosis" is easy: simply connect a multimeter to the device and measure the resistance at the contacts. Normally, the reading should range from 2 to 4 kOhm. Any deviations will require replacement.

Afterwards, it's a good idea to check the inlet valve screen. It often becomes clogged and blocked by dirt, preventing water from passing through. Fixing this is simple: remove the filter, clean it, rinse it, and replace it.

Be sure to check the fittings for molded plastic inserts. These control the flow of water into the whirlpool, but they often collapse, impeding the flow. As a result, the flow becomes too strong, the system detects an overflow, and displays error code F13.

The inlet valve is not repairable.

A Whirlpool cannot be operated with a broken valve. Ignoring the problem and trying to temporarily reset the error will only make the situation worse. The load will freeze the board or cause a flood. It's best not to delay repairs.

How to replace a part?

The valve is considered non-repairable—a faulty device is easier to replace than to repair. The device costs between $2 and $30, depending on the serial number of the Whirlpool washing machine. But first, the broken part must be removed according to the following instructions:

The valve is considered non-repairable—a faulty device is easier to replace than to repair. The device costs between $2 and $30, depending on the serial number of the Whirlpool washing machine. But first, the broken part must be removed according to the following instructions:

- check that the washing machine is disconnected from the power supply and water supply;

- disconnect the wires and pipes connected to the valve by loosening the corresponding clamps;

- loosen the fixing screws;

- pull back the plastic latches (if present);

- remove the valve.

Afterwards, install the new valve, connect the machine to the power supply, and run a test wash. If the F13 error code doesn't appear, everything was done correctly.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment