Gorenje washing machine error code F4

Gorenje washing machines rarely display the F4 error code. If you see this error code on the display, you can either immediately contact a service center and pay for diagnostics and repairs, or investigate the problem and fix the issue yourself. Let's look at what the error means and which components of the machine need to be checked.

Gorenje washing machines rarely display the F4 error code. If you see this error code on the display, you can either immediately contact a service center and pay for diagnostics and repairs, or investigate the problem and fix the issue yourself. Let's look at what the error means and which components of the machine need to be checked.

What does the error indicate?

A breakdown of all the errors your Gorenje washing machine may display is included in the machine's manual. Therefore, if you notice your machine has stopped working, you should immediately consult the user manual. Fault code F4 informs about a breakdown of the tachometer sensor or motor, or a break in the wiring between them. Very rarely, the problem may lie with the main control module, or more precisely, with a faulty triac, which controls the motor and tachogenerator. What can happen to an electric motor? Typically, the following occurs:

- wear of collector brushes;

- defect of lamellas;

- problems with the stator or rotor winding;

- break in power supply wiring.

When it comes to the Hall sensor, its contacts usually come loose or the mounting hardware becomes loose. In either case, your Gorenje washing machine will require diagnostics. Let's figure out what to do first, how to diagnose it, and how to repair it yourself.

The machine is checked one by one: first the tachometer, then the engine, and only then the control board.

Let's check the speed sensor

One of the causes of error F4 is a problem with the Hall sensor. The tachogenerator is located on the electric motor rotor and monitors its speed. To check the element, you need to:

- de-energize the washing machine;

- turn off the tap that supplies water;

- detach the drain and fill hoses from the body;

- Unscrew the screws holding the back panel. Remove the wall and set it aside;

- carefully remove the drive belt from the drum pulley and engine;

- Disconnect the wires from the electric motor. Before disconnecting them, it's best to take a photo of the wiring diagram. This will help you avoid mistakes during reassembly;

- unscrew the screws securing the engine;

- carefully rock the engine from side to side and pull the motor out of the housing.

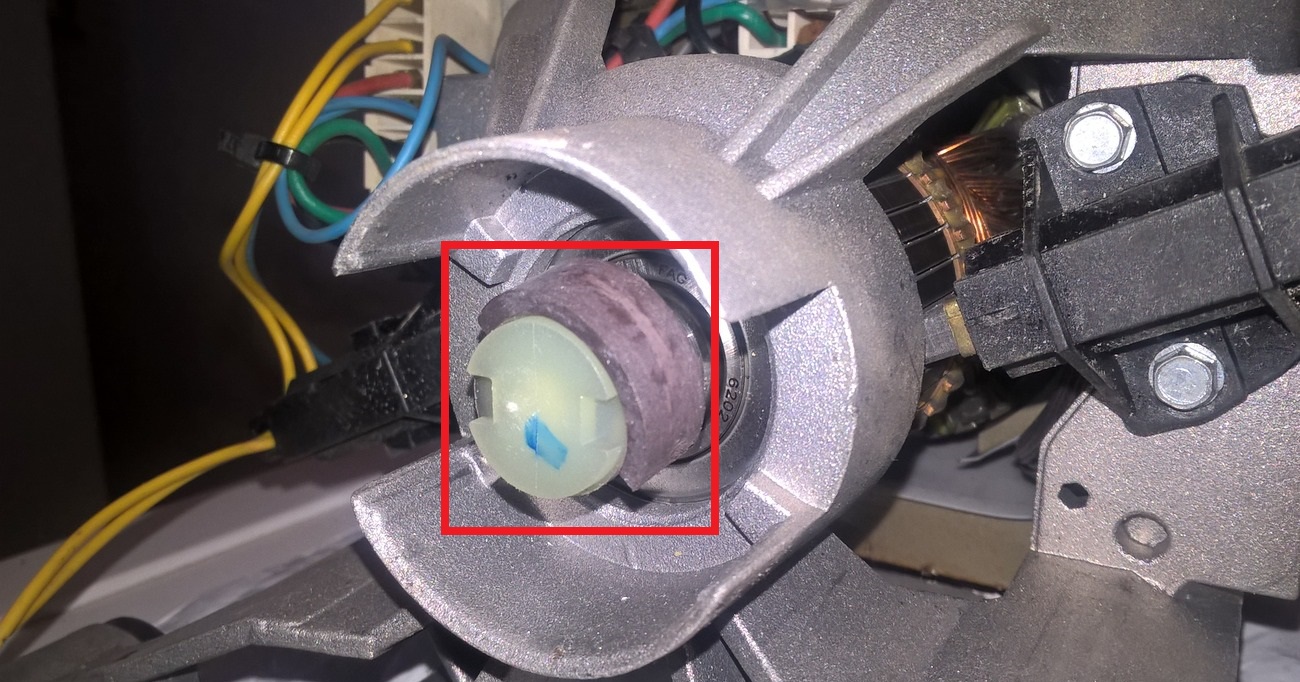

Now that you have the engine in hand, you can take a closer look at the tachogenerator. Sometimes, due to strong vibrations from the washing machine, the element contacts come loose or its fasteners become loose. To fix this, simply tighten the fasteners or restore the connection in the circuit. If no defects are visible externally, you should check the tachogenerator with a special device – a multimeter.

Set the tester to ohmmeter mode and place the probes on the Hall sensor contacts. If the meter screen displays a value of approximately 60-70 ohms, the tachogenerator is working properly.

Next, switch the multimeter to voltage measurement mode. At this stage, you can determine whether the component is generating current. The tester probes should also be placed against the Hall sensor and the values on the screen read. If the readings fluctuate within 0.2 volts, the tachogenerator is not faulty. Typically, tachogenerators rarely fail. In most cases, the cause of the F4 error is loose contacts. Therefore, the first step is to ensure the integrity of the wiring.

Graphite brushes and other motor components

If the tachometer sensor is OK and is not the cause of the F4 error message, you'll need to check the engine. First, inspect the motor brushes. These are graphite rods located on the sides of the motor housing.

Gorenje washing machine brushes can wear out within 5-6 years. They wear out and stop transmitting current to the motor rotor. This prevents the motor from rotating. If severely worn, the motor may even spark. You can assess the condition of the brushes by disconnecting the wires, moving the terminal, and removing the graphite rod. If the rod is worn down by more than 50%, the brushes must be replaced.

In any case, the commutator brushes are only changed in pairs.

Even if only one rod is worn, two elements will need to be replaced. The worn brushes should be removed, the area cleaned of graphite shavings, and new parts installed. Next, connect the wires, and the motor is returned to the housing.

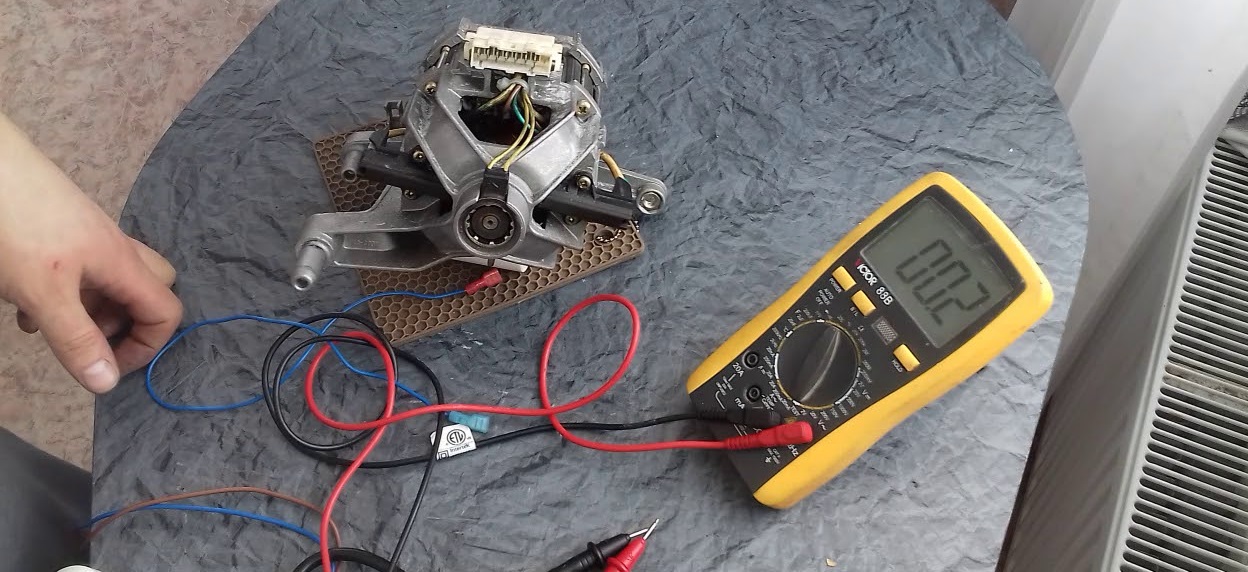

If the brushes are in good condition, you can proceed to checking the rotor winding. When a short circuit occurs, the motor overheats, the protection circuit is activated, and the motor will not start. A multimeter will be required for diagnostics. The procedure is as follows:

- set the multimeter switch to the resistance measurement mode;

- apply the tester probes to the lamellas;

- evaluate the values on the device screen.

Normally, the multimeter should display a resistance of 20 to 200 ohms. If the rotor winding is open, the reading on the meter screen will approach infinity. Conversely, if there is a short, the reading on the tester will be minimal. You should also set the multimeter to buzzer mode. This test can reliably rule out a short. Place the first probe of the tester against the rotor, and the second probe against each lamella in turn. If the device begins to beep, the motor is faulty.

The stator winding must also be checked. Connect the wires together and place the multimeter probe (the tester should be set to buzzer mode) on the connection. If a short circuit occurs, the multimeter will beep.

To reset the F4 code, you'll need to eliminate the cause. In this case, it's best to buy and install a new engine. Rewinding the winding is quite difficult, and the cost of such work is comparable to purchasing a new motor. Besides short circuits and open windings, the motor fins may be the culprit. Sometimes the fins delaminate, so inspect them. If defects are detected, you can try to correct the problem by machining the surface of the components on a lathe.

Very rarely, the F4 error indicates a faulty control module in a Gorenje washing machine. It's best not to mess with the machine's internal circuitry yourself, as you could cause further damage. It's best to call a professional. A specialist will diagnose the circuit board and repair your "home assistant."

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment