Gorenje washing machine error code F5

If you encounter the F5 error code in your Gorenje washing machine, don't delay. This code is among the most dangerous, so don't delay troubleshooting. Which parts are at risk, where to look for the culprit, and how to repair the machine? We'll cover all of this in detail.

If you encounter the F5 error code in your Gorenje washing machine, don't delay. This code is among the most dangerous, so don't delay troubleshooting. Which parts are at risk, where to look for the culprit, and how to repair the machine? We'll cover all of this in detail.

Why did this code appear?

In 50% of cases, the F5 error on Gorenje washing machines is caused by electronic components, requiring expensive control board firmware upgrades. Modern washing machines are sensitive to power surges, especially during the spin cycle. If the current fluctuates during this period, the motor control circuit malfunctions, and the electronics lose control.

To prevent power surges from affecting your washing machine's electronics, consider installing a power stabilizer in the circuit.

Error F5 also indicates motor overheating. This occurs with prolonged, continuous use of the washing machine. The code often appears on the display if the user immediately switches to a new program after a 2-3 hour cycle. In this case, the system detects elevated motor temperature and issues a warning code. To correct the situation, it is enough to let the machine rest for 15-30 minutes.

Inspection and repair

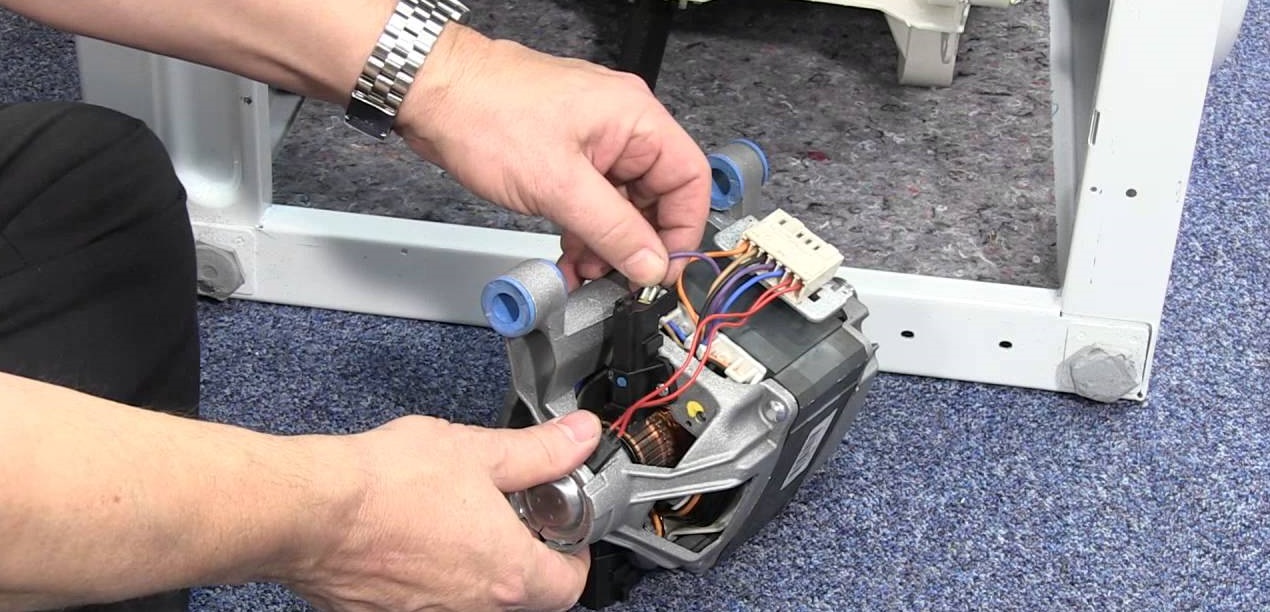

If the motor has cooled down but the F5 error persists, you'll need to figure out what to do next. The main focus will be the washing machine's motor, which needs to be removed from the housing and inspected for leaks and damage. Disconnect the machine from the power supply, water supply, and sewer lines, and begin partial disassembly.

- We unscrew the screws from the back panel, remove it and put it aside.

- We find and remove the drive belt by pulling out the rubber band while simultaneously rotating the pulley.

To avoid errors during reassembly, it is recommended to record the location of the wiring connected to the engine with a camera.

- We loosen the bolts holding the engine and, shaking the part, remove it from its seat.

From this point, the actual repair begins, which involves a step-by-step inspection of all the motor's weak points. First on the list are the electric brushes, which are made of graphite and wear down on the motor housing during machine operation. If the tip wears down significantly, electricity is not transmitted to the motor, the drum stops rotating, and the brushes themselves begin to spark. Therefore, we unclip the wiring, release the clamp, and assess the condition of the "carbon" brushes. When half of them are worn down, we replace them as follows:

The electric brushes on the engine are changed in pairs, even if one of them is intact.

- we remove graphite dust from the seats;

- we purchase similar brushes;

- we clamp the spring and insert it into the “socket”;

- We return the terminal and connect the wiring.

If the brushes are still intact, we continue troubleshooting by checking the rotor winding. If there's a short or open circuit, the motor doesn't operate at full power, causing the drum to rotate too slowly or stop. The motor often stops because the motor thermostat indicates the temperature is too high, triggering the automatic protection system and shutting down. However, even a slight increase in temperature can cause the fins to peel off and cause other negative consequences. Checking the winding yourself is easy.

- We set the multimeter to resistance mode.

- We connect the probes to the two lamellas.

- We evaluate the display. If the values are between 20 and 200 ohms, the part is OK. Exceeding the normal range indicates a break, while low values indicate a short circuit.

- We check to see if the rotor is shorted. Turn on the tester's buzzer mode, attach one probe to the rotor, and then attach the other probe to the fins, one at a time.

- Listen carefully. The absence of a squeak confirms the rotor is working properly and there is no damage.

Next, we check the integrity of the stator windings. We short-circuit the wiring, apply the tester probe in buzzer mode, and listen again. A beeping sound will indicate a short circuit and a burnt-out motor. Repairing the motor in this case is useless, and rewinding the winding is expensive and impractical. It is better to replace the engine with a working one.

The F5 error can also be caused by lamella detachment, either due to heat or bearing seizure. Seizures can also occur if a program is run with the drum open in top-loading machines. In either case, contact with the rotor is lost, and the motor operates improperly. This can be resolved by turning the affected areas on a lathe.

If there's no doubt about the engine's functionality, the control board is at fault in the F5. We strongly advise against attempting to repair the module yourself. It's best to contact a professional immediately.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment