Gorenje washing machine error F7

Error code F7 appears in a Gorenje washing machine when there's a problem with the water drainage. While experienced technicians can immediately identify the source of the problem, ordinary users are forced to settle for a vague explanation of the code. To determine the cause of the machine's malfunction, you'll need to partially disassemble the washing machine and diagnose each element of the drainage system. We'll provide step-by-step instructions and explanations below.

Error code F7 appears in a Gorenje washing machine when there's a problem with the water drainage. While experienced technicians can immediately identify the source of the problem, ordinary users are forced to settle for a vague explanation of the code. To determine the cause of the machine's malfunction, you'll need to partially disassemble the washing machine and diagnose each element of the drainage system. We'll provide step-by-step instructions and explanations below.

Decoding the code

If your Gorenje washing machine displays error code F7, it means there's a problem with the wastewater drainage system. The water drains too slowly, and the level never drops below the "minimum" mark. First, the system attempts to repeat the drain cycle, and if unsuccessful, it alerts the user to a malfunction with a special code. Difficulties with drainage arise for the following reasons:

- faulty or heavily clogged pump;

- clogged waste filter;

- drain pump power failure;

- broken pressure switch;

- problems with the control board.

Error F7 indicates problems with the pump, debris filter, pressure switch, or control board.

To identify the root cause and fix the problem, you'll need to diagnose each of the washing machine's components. Start with the simplest—the debris filter—and gradually move on to the drain pump and pressure switch. It's best not to attempt to tinker with the control board yourself, as this complex mechanism can easily be damaged and permanently ruined.

Let's check the filter

Diagnostics begin with the simplest step: cleaning the dust filter. This is a plastic coil that collects dirt and other debris that gets into the machine. It's located in the lower right corner of the Gorenje washing machine, behind a round or square access hatch. Before checking and cleaning the plastic filter, it must be removed.

- Disconnect the machine from the power supply and water supply.

- Using a knife or a screwdriver, pry the hatch open, release the latches, and open it.

- Place a cloth nearby or place a container to collect the water.

- Holding the lug on the filter, unscrew the filter clockwise.

Do not remove the debris filter immediately after the end of the cycle - the water will not have time to cool down.

Now we begin the actual repair. Rinse the filter under running warm water, first removing any debris and deposits from the coil. If the layer of dirt is too thick, you can soak it in a solution containing citric acid for 20-40 minutes.

Don't limit yourself to cleaning the debris filter alone. It's also a good idea to check the pump, volute, and drain pipes for blockages. Use a flashlight to shine a light on each component, and if any foreign objects are found, remove them with pliers or tongs. Pay special attention to the pump impeller, as hair often gets caught in it, causing a malfunction and the F7 error.

Testing the drain pump

Error code F7 also appears due to a power failure on the drain pump. To check the pump, you'll need to remove it and inspect it carefully. To do this, look inside the housing through the missing bottom. Disconnect the circuit breaker from the power supply, place the unit on its back, and begin the inspection:

Before turning the machine on its back, make sure there is no water in the dispenser and drum, otherwise a leak will occur.

- remove the connectors or terminals from the pump;

- we connect the terminals from a pre-prepared conductor with a plug to the pump;

- We check the reliability of the connection and the absence of third-party contacts;

- plug the plug directly into the socket;

- Assess the situation. If the pump starts working and water begins to drain, then the drainage system is fine, and the drainage problem should be looked for in the control board or pressure switch;

Another way to diagnose the pump is to place the multimeter probes in resistance mode across the contacts. Normally, the reading should be in the range of 150-260 ohms. If the display shows "0," a short circuit is confirmed, and if the reading exceeds the normal value, an open stator winding is present. If there are any deviations, the part will have to be replaced, since repairing it yourself is unprofitable, difficult, and sometimes even impossible.After replacement, test the drainage again with 220 volts. A mechanical check of the pump is also acceptable, as follows:

- snail removal;

- Impeller rotation. Ideally, the rotation is intermittent, as the rotor is made of a magnet and moves in jerks;

- The impeller wobbles sideways across the axis. Even the slightest play indicates a malfunction and requires pump replacement;

- Connect the motor to the power supply via a power cord and outlet. The device should operate smoothly and quietly.

A replacement pump is selected based on its serial number. Ideally, the original is purchased and installed, but installing an equivalent pump with similar characteristics is also acceptable. The main thing is that the new pump has the same capacity and the same mounting method.

Let's check the pressure switch tube

If the drainage system is clean and functioning properly, it's time to check the pressure switch. It's the level sensor that transmits information about the tank's fullness to the control board, initiating the filling or draining of water. When the tube becomes clogged or loses contact with the module, the readings are displayed incorrectly and the system returns an F7 error.You can confirm or refute your guess by following the instructions.

When carrying out repairs, remember safety precautions and disconnect the washing machine from the power supply.

- Disconnect the washing machine from the power supply and water supply.

- We unscrew the bolts holding the top cover of the machine and move the panel forward.

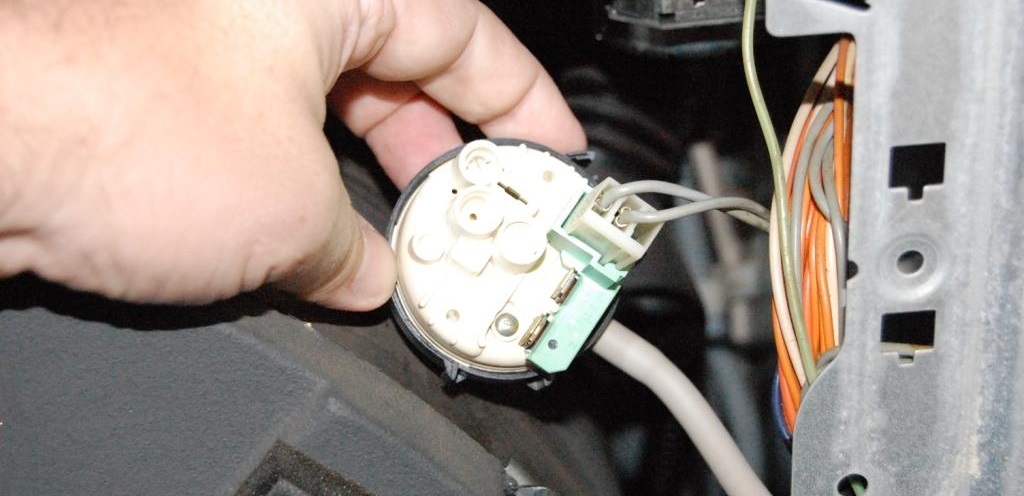

- We are looking for a pressure switch – a round plastic box of black or white color.

- We unscrew the bolts and disconnect the wiring, removing the sensor with the tube from the housing.

- We inspect the box and tube for damage or blockages.

The key step is to check the pressure switch for proper operation. You'll need a tube with a diameter equal to the sensor's nozzle, which should be inserted into the pressure hose. Then, gently blow into the hole. If the contacts are closed and the device is working, you'll hear 2-3 distinctive clicks. Otherwise, the only solution is to completely replace the device.

If the pump, debris filter, hoses, and level sensor are all working properly, the problem lies with the control board. Figuring out how and what to do here is futile—it's practically impossible to fix the electronics yourself. It's best to contact professional repairmen immediately.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment