Error code FC2 on a Haier washing machine

Washing machine owners often encounter an error code that indicates a loss of communication between the control module and the motor, preventing the motor from understanding whether the component is working or not. In this scenario, there's a good chance the module is fine, but what's the problem and how to fix it? Today, we'll explore the possible causes of the FC2 error on a Haier washing machine and help you conduct an effective diagnosis.

Washing machine owners often encounter an error code that indicates a loss of communication between the control module and the motor, preventing the motor from understanding whether the component is working or not. In this scenario, there's a good chance the module is fine, but what's the problem and how to fix it? Today, we'll explore the possible causes of the FC2 error on a Haier washing machine and help you conduct an effective diagnosis.

Testing the engine

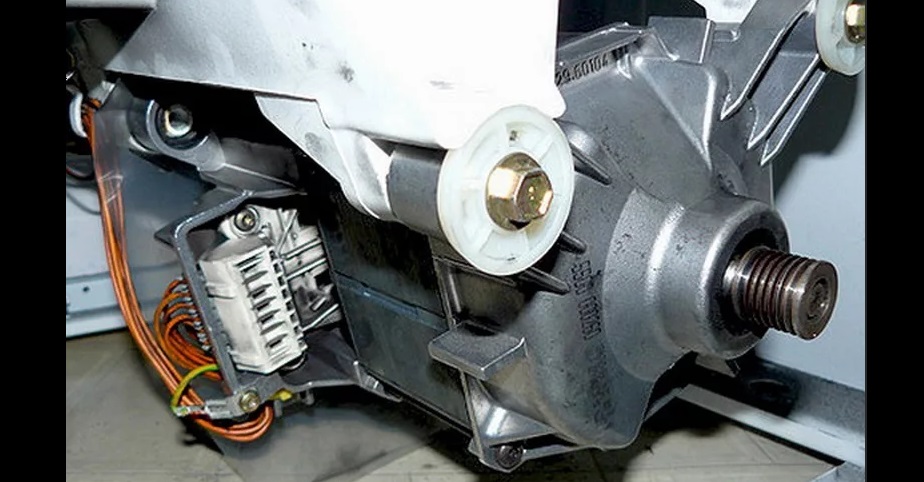

You can check the machine's motor yourself; the main thing is to know how. You'll need to study the type and operating principle of the motor installed in the machine. For example, Haier washing machines are equipped with commutator motors that operate with a drive belt. Compared to inverter motors, they are more compact and easier to operate. However, they do have a drawback: the commutators often fail, meaning you'll need to service them sooner or later.

The structure of such motors includes a rotor, a stator, and two brushes. The fins and winding are responsible for transmitting current within the mechanism. The motor also contains a sensor that monitors the speed of the motor. When performing a self-diagnosis, it is necessary to check each of the aforementioned components sequentially. But first, you need to do the following:

- remove the back panel from the CM case;

- pull the drive belt off the pulley;

- find the engine, which is located under the tank on the right side;

- take a photo of the connector or remember the location of the terminals to make it easier to connect everything back later;

- turn off the wiring connected to the motor;

- loosen the fixing bolts;

- rock and remove the engine from the "nest".

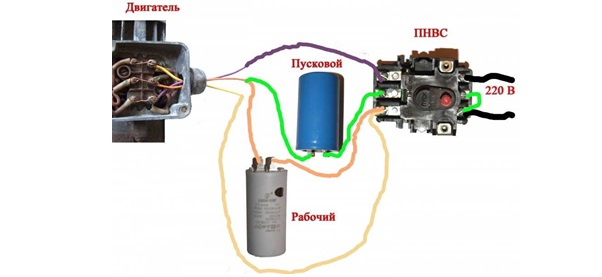

Let's start by checking the motor itself. The process is quite simple. Connect the stator winding wires to the rotor and apply 220 volts to them.

If the motor starts and the shaft begins to rotate, then the device is working properly!

In this case, you can begin checking the individual components of the "home assistant" mechanism. If there is still no movement, this is a clear sign of a malfunction. In this case, repairs will be required.

It's important to remember that even simple testing requires extreme caution. First, be careful when working with voltage to avoid any unpleasant situations. Second, avoid overheating the motor when directly connected. It's best to play it safe and turn on a heating element, which will heat up and absorb the shock if a current leak occurs. Third, remember that such diagnostics only cover the surface and don't provide a complete picture of the component's operation at different speeds.

It's worth looking at the brushes

The next diagnostic step involves the electric brushes. These are located on the motor housing and smooth out friction using specially designed carbon tips. If they wear out, the motor overheats, causing it to spark. The board detects this and generates an FC2 error. To check the condition of the electric brushes, you will need to:

- unscrew the fixing bolts;

- compress the spring;

- detach the brushes from the housing;

- open each "case";

- measure the length of the tips.

When choosing new parts, pay attention to the serial number of your Haier model. If the length of the "carbon" on one of the brushes is less than 1.5 cm, an error code will appear on the display. The only solution is to replace both brushes in pairs. Install the new brushes according to the instructions in reverse order.

What else needs to be tested?

The diagnostic process also includes checking the lamellas. These are metal plates attached to the shaft and used to transmit current to the rotor. Over time, they can become damaged or peel off, which ultimately leads to motor failure. In case of minor defects, it will be enough to polish the burrs with sandpaper, but in case of serious damage, a complete replacement of the part may be required.

The FC2 error can occur due to a problem with the winding: the motor fails to start or doesn't accelerate quickly. This, in turn, causes a short circuit, causing the motor to overheat. The thermistor detects this, forcing the control board to reset the program. Ultimately, either the temperature sensor or the motor itself fails. A thorough winding test with a multimeter is essential. The procedure is as follows:

- turn on “Ohmmeter”;

- touch the lamellas with feeler gauges;

- look at the result (20 to 200 Ohm is normal, deviations indicate a short circuit or open circuit).

After these manipulations, we use a buzzer to test the stator for a breakdown. If a current leak is detected, the only way to fix the problem is to replace the motor. We purchase a new motor, install it ourselves, and run a test wash cycle.

If the FC2 error persists after performing all diagnostic procedures, you'll likely need to contact a professional service center. Our technicians will conduct tests and help you troubleshoot the problem. Remember, regular maintenance and timely troubleshooting of your washing machine will help keep your appliance in good working order and extend its lifespan.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment