UNB error in Haier washing machine

The longer and more intensively we use our home appliances, the higher the chance of encountering some kind of error message on the display. The UNB error message is one of the most common errors in Haier washing machines, so nearly one in three users of this brand's "home helper" has encountered this problem. It occurs when the machine detects an imbalance, which can occur when clothes inside the drum form a large, tight lump and begin slamming against the drum walls during the spin cycle. However, the error isn't always caused by clothes, which is what we'll explore today.

The longer and more intensively we use our home appliances, the higher the chance of encountering some kind of error message on the display. The UNB error message is one of the most common errors in Haier washing machines, so nearly one in three users of this brand's "home helper" has encountered this problem. It occurs when the machine detects an imbalance, which can occur when clothes inside the drum form a large, tight lump and begin slamming against the drum walls during the spin cycle. However, the error isn't always caused by clothes, which is what we'll explore today.

Causes of imbalance

A malfunction caused by imbalance is often associated with laundry that has gathered into a large lump during the washing process, creating the illusion of a strong overload. The error could also have been caused by actual overload, if the user mistakenly loaded too many clothes. If this is the problem, it's very easy to fix yourself—just remove excess laundry if overloading is the culprit, or evenly arrange the clothes if they've bunched up. But what if the problem isn't the laundry?

- The shipping bolts weren't removed. It's quite common for a homeowner to unknowingly fail to remove the bolts that hold the drum in place during shipping. If they aren't removed before a cycle, the machine will spin with the drum locked and the tub still in place. This can damage the internal components. Never operate your "home helper" until the bolts are removed from the back of the washer.

Running a washing machine with shipping bolts in place will void the manufacturer's and store's warranty, so be sure to check them if you don't want to pay for repairs out of your own pocket.

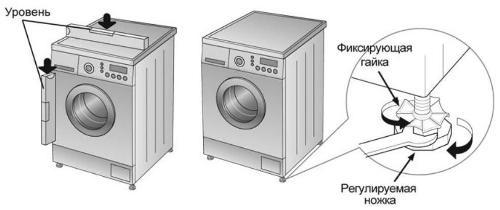

- Installation errors. Household appliances must be placed on as level a surface as possible to prevent excessive vibration and imbalance during operation. Therefore, it's best to carefully level the floor before installation and purchase a special anti-vibration rubber mat or special rubber feet. It's best to place the appliance on tile or concrete, avoiding laminate, linoleum, carpet, and other unstable surfaces.

- Damper failure. These components are designed to reduce machine vibration during operation. If the rubber pads in the dampers have worn out over time and the fasteners have become loose, the machine will suffer from serious imbalances during the spin and wash cycles. Checking the damper is easy: open the top panel of the washing machine and gently press down on the drum. If it bounces a few centimeters and stops, all is well. However, if after these manipulations you observe erratic side-to-side movements accompanied by jerking, the component needs repair or replacement.

- Counterweight failure. The washing machine's shock-absorbing system consists not only of dampers but also of concrete counterweights installed in the machine to actively dampen vibration. When these concrete blocks are damaged, not only are they unable to reduce vibration and system imbalance, but they also actively strike other machine components, posing an additional risk to expensive equipment. If the counterweight is cracked or its supporting element is worn, it must be replaced or repaired manually.

If the cracks in the counterweight are not too large, then you can try to treat them with concentrated cement mortar.

- Bearing problems. Finally, it's worth considering a bearing failure, which can be identified by extremely slow drum rotation, accompanied by an unpleasant clanking noise. If you notice this behavior in your washer, it's likely this problem is the cause of the UNB error. In this case, you'll need to call a service center specialist, as bearing repairs and replacements are best left to professionals.

It's believed that if a washing machine is installed correctly and operated strictly according to expert recommendations, it will last approximately 5-7 years longer than the standard warranty period. This is why it's so important to prevent system imbalances. It is very convenient that many modern washing machines have an automatic rebalancing function, which prevents errors from occurring. UNB, which extends the overall service life of the equipment.

Why does the machine detect imbalance?

An imbalance may seem harmless, so it's not necessary to monitor it so closely. In fact, correcting this problem is crucial, not least because it negatively impacts the washing machine's motor, its shock-absorbing system, and other key internal components. Users can almost always detect overload during the spin cycle – the machine will vibrate excessively, bounce, and make unusual sounds. To address this unpleasant situation, Italian and Korean appliance manufacturers have developed special automatic balancing systems.

Its principle is that special sensors are located in the drum, monitoring the accumulation of items in one area of the drum. As soon as the machine detects the slightest overload, it sends a signal to the control board, which stops the cycle and initiates reverse rotation of the drum, thus eliminating the imbalance. Furthermore, if the "home assistant" is unable to handle the laundry in the drum due to a clumped mess, it notifies the user, so they can correct the system's balance. This cutting-edge technology helps prevent previously unavoidable breakdowns.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment