How to connect a motor from an Indesit washing machine?

An Indesit washing machine's electric motor can be reused even after the machine breaks down. For example, you can turn the motor into an electric sander, a very useful tool for a garage or summer house. To assemble the device, you'll need to attach an sanding stone to the motor shaft. It will rotate around its axis, allowing you to sharpen table knives, garden shovels, axes, and other tools. There are also other uses for the motor—there are many devices that require rotation. Let's consider how to connect an Indesit washing machine motor to make it spin.

An Indesit washing machine's electric motor can be reused even after the machine breaks down. For example, you can turn the motor into an electric sander, a very useful tool for a garage or summer house. To assemble the device, you'll need to attach an sanding stone to the motor shaft. It will rotate around its axis, allowing you to sharpen table knives, garden shovels, axes, and other tools. There are also other uses for the motor—there are many devices that require rotation. Let's consider how to connect an Indesit washing machine motor to make it spin.

Need a diagram

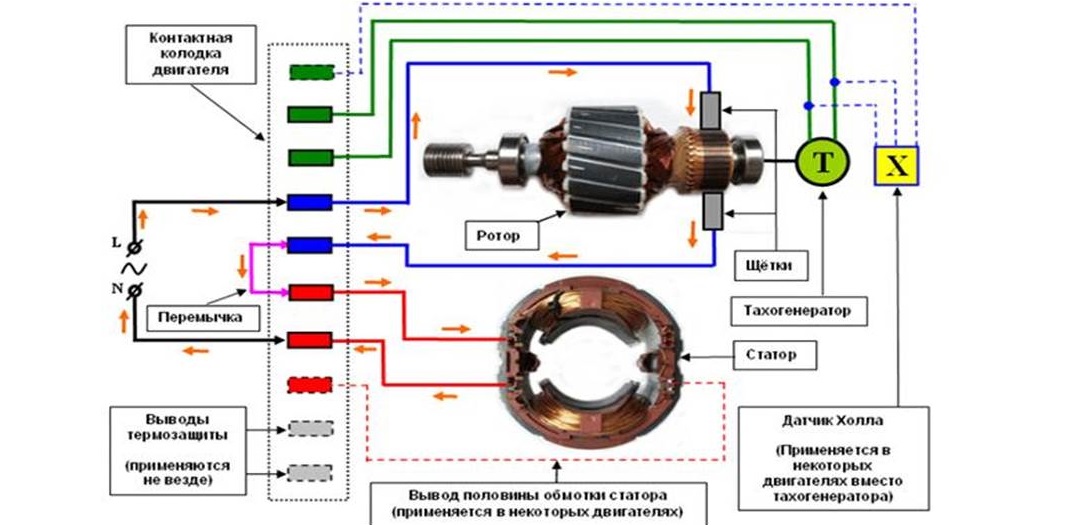

If you've found a use for the working motor from an old washing machine, you should figure out how to connect the motor to the electrical network. Before starting work, you need to carefully study the electrical wiring diagram of the motor and understand how it works in the washing machine.

Connecting the electric motor is fairly quick and doesn't take much time. Initially, it may seem like there are too many wires coming from the motor. However, after analyzing the diagram above, you'll realize that not all of them will be used. You'll need to work specifically with the rotor and stator wires.

Find the right conductor

After studying the diagram, the electric motor's operation should become clear. Looking at the wiring harness from the front, in most cases, the first pair of left wires connects to the Hall sensor, which regulates the washing machine's motor speed. If you're building a homemade device, you won't need them.

Next are the important stator wires, which are colored reddish and brown. Next come the cables leading to the rotor brushes, which are colored gray and green.

To connect the washing machine's electric motor, you will need 4 wires: two stator wires and 2 rotor wires.

To start the motor from the mains, a starting capacitor is not required. The motor itself also does not require a starting winding. Next, the motor wires are checked with a multimeter set to resistance mode. Touch the wire with one probe of the tester, and find its pair with the other probe.

The tachometer wires will show a resistance of about 70 ohms. They should be set aside. The remaining wires are also tested with a multimeter to find the correct pair.

We set the engine in motion

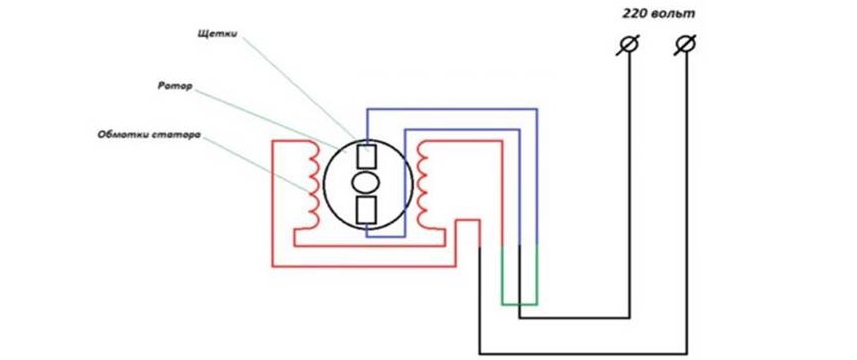

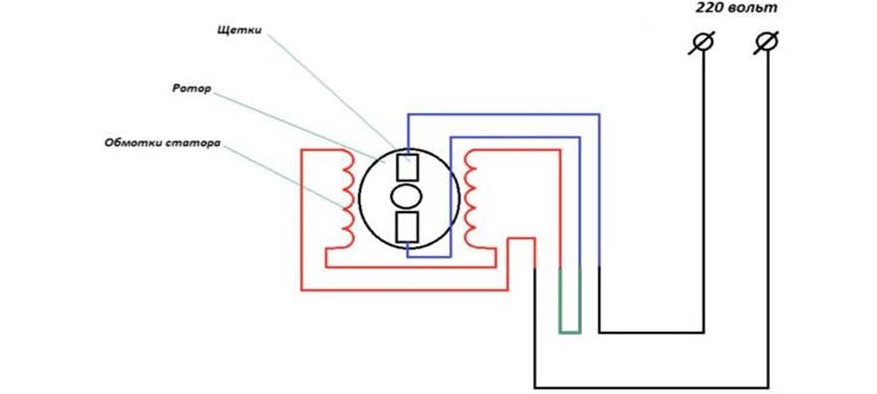

Once the wire pairs are identified, all that's left is to carefully connect them. How do you do this? Using the diagram as a guide, connect the end of the stator winding to the rotor brush. It's best to build a jumper here and consider insulating it.

The jumper is marked in green in the figure. After completing this step, two wires will remain: the end of the rotor winding and the cable going to the brush. 220V voltage is supplied to these ends. When plugged into the power supply, the motor will begin to rotate. Washing machine motors are very powerful, so extreme care must be taken when handling this homemade device. It is advisable to secure the motor to a suitable, level surface before using the device.

If you need to change the motor's rotation direction, you need to jumper the wires to different locations and rewire the rotor brushes. The diagram shows how to do this.

If you follow the instructions, the electric motor will start working and serve you faithfully for a long time. If the motor still doesn't turn, you should make sure it's working properly.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment