Connecting the motor from the Vyatka-automatic washing machine

Vyatka-avtomat washing machines, manufactured by the Kirov plant "Vesta," have been in production since 1981. At that time, the machines were built to last, so these models were equipped with powerful and extremely reliable electric motors. Even after 20-30 years, these motors, in most cases, are still capable of performing their intended functions.

Vyatka-avtomat washing machines, manufactured by the Kirov plant "Vesta," have been in production since 1981. At that time, the machines were built to last, so these models were equipped with powerful and extremely reliable electric motors. Even after 20-30 years, these motors, in most cases, are still capable of performing their intended functions.

Many people have these "perpetual motion" motors gathering dust in their garages, which could be used in a variety of homemade devices. For example, you could build a lathe, grinding machine, or a small concrete mixer. We'll figure out how to properly connect the electric motor from a Vyatka-automatic washing machine. We'll also explain how to test the motor for functionality.

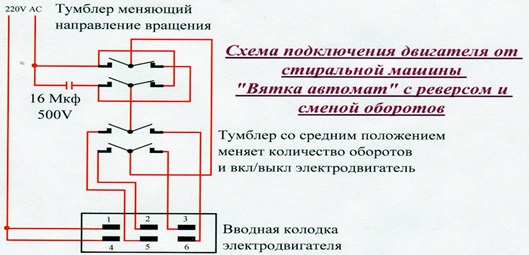

Engine connection diagram

The motor from the Vyatka-automatic washing machine is designed to operate in a single-phase network. The machine's motor consists of a pair of reverse and a pair of working coils. Together with the starting capacitor, they set the direction of rotation of the rotor.

Vyatka washing machines of different years have different motor modifications. However, overall, the motor specifications are roughly the same. All electric motors had only two rotor speeds: up to 2200 rpm during the spin cycle and up to 450 rpm during the main wash cycle.

The electric motor from the Vyatka-automatic washing machine may have 5 or 6 terminals for connection (motors with 8 terminals are extremely rare).

Regardless of whether your motor has 5 or 6 terminals, the wiring diagram will be identical. However, in motors with six terminals, contacts 1 and 4 must be shorted to create a common terminal for connection to the power grid.

For the simplest connection of the Vyatka-automatic washing machine motor (directly to the outlet, without a capacitor or switch), you will need:

- power plug;

- three wires with plugs.

A separate wire with a plug must be connected to one end of the plug, and a split cable with different plugs must be connected to the other. Next, locate terminals 1 and 4 on the electric motor. The connector numbers can be found directly on the plastic housing protecting the terminals.

The first and fourth terminals must be connected to a single wire, so the plugs of the "split" cable are connected to them one by one. The second, separate cable is connected to terminal #2. After this, you can plug the plug into the power outlet – the rotor will begin to rotate.

To ensure the reversal of the electric motor, that is, changing the direction of rotation of the rotor to the opposite, it will be necessary to constantly manually swap the positions of the ends of the winding. For convenience, it is better to immediately include a toggle switch in the circuit - then the motor's direction of movement can be switched with a click.

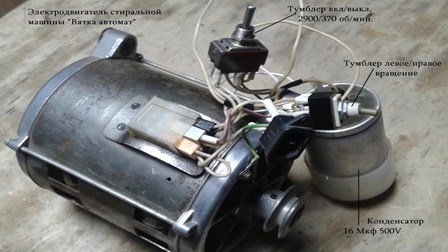

Additionally, to protect the motor from increased loads, it's advisable to include a capacitor in the circuit. Vyatka-automatic washing machines are standardly equipped with a 16 µF, 500 V starting device.

The connection diagram for the motor with a reverser, a toggle switch for adjusting the speed of rotation and a starting protective capacitor is shown in the figure.

Thus, contacts 1 and 4 of the electric motor are also shorted together with a bifurcated wire and connected to one of the plug's pins. Further connection is made according to the diagram. The second and fifth pins are connected to the terminals of the first toggle switch, which will change the motor speed and turn the engine on/off. Outputs 3 and 6 are also connected here, in pairs, to the opposite contacts.

Next, a toggle switch for reversing is added to the circuit. It is connected by wires to the middle switch, and its diagonal contacts are powered together. The common wire is connected to the starting capacitor, from which the power cable is connected to the plug. The design is shown in the figure below.

If done correctly, the Vyatka washing machine's motor will start easily in both directions. It's important to secure the motor securely in place before use, otherwise it could damage its own wiring during operation.

The direction of movement can be changed using the toggle switch only after the rotor has come to a complete stop.

Engine test

If you've found a Vyatka-automatic washing machine engine gathering dust on a shelf in your garage and want to use it, but aren't sure if it's working, run a diagnostic on it. To test an electric motor, you will need the simplest multimeter and a special digital meter for power, voltage, and current. You can purchase devices in specialized stores or online.

To begin, it's best to measure the resistance of the motor windings with a multimeter. Set the tester to the appropriate mode and alternately touch the probes to the pairs of contacts. Normally, the display will show the following:

- when measuring the resistance between terminals 1 and 5 – 23.2-26.8 Ohm;

- between contacts 1 and 2 – 8-9.2 Ohm;

- 4 and 3 – 51.1-58.9 Ohm;

- 4 and 6 – 51.1-58.9 Ohm;

- between 3 and 6 – 71.6-82.4 Ohm.

If the winding resistance meets the specified values, the motor can usually be used for secondary purposes. However, it's best to perform a more thorough diagnostic and check how the motor handles loads, whether it overheats, and what RPM it produces. For these purposes, you'll need a special power, voltage, and current meter.

Ideally, the readings at low and high RPMs should be the same, whether the rotor is rotating clockwise or counterclockwise. If everything is normal, when the engine accelerates to 370 RPM, the measuring device should display readings similar to these:

- voltage 220-230 volts;

- power – 290-310 watts (the figure depends on the specific engine model, your electric motor may be more powerful);

- current strength - 1.4-1.5 Amperes.

The results should be similar when increasing the RPM. If the electric motor is in good condition, it can be connected as described above. It can be used to create many useful household devices: an emery machine, a lathe, a grain or apple crusher, a lawn mower, a concrete mixer, etc.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment