How to connect a motor from an old washing machine?

Washing machines manufactured 15-25 years ago are typically equipped with either brushed or asynchronous motors. Inverter motors are found in more modern machines and are rarely used for secondary purposes. Therefore, let's look at how to connect a motor from an old washing machine. We'll explain what you need to know and the specifics of connecting different types of devices to the electrical circuit.

Washing machines manufactured 15-25 years ago are typically equipped with either brushed or asynchronous motors. Inverter motors are found in more modern machines and are rarely used for secondary purposes. Therefore, let's look at how to connect a motor from an old washing machine. We'll explain what you need to know and the specifics of connecting different types of devices to the electrical circuit.

Single-phase asynchronous motor

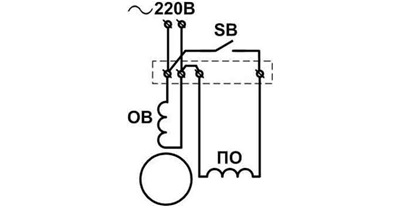

This type of motor is only found in very old automatic and semi-automatic washing machines. Before attempting to connect the device, check it with a multimeter. Set the tester to resistance and find the wires that "constantly" connect. The remaining two terminals are the second winding pair.

Next, you need to determine which winding is which. This can be done by eye—the jumper wires are smaller in cross-section than the main wires. It's still best to use a multimeter to determine the winding type.

The starting winding will produce a higher resistance, the working winding will produce a lower one.

The starting winding is necessary to generate initial torque. In most cases, it operates only for a few seconds after the motor starts. The working winding is needed to maintain the rotating magnetic field; it remains active until the motor is disconnected from the network.

In addition to the two types of windings, the motor circuit also includes a contactor or capacitor with a capacity of 2 to 4 μF. If the motor is to be used without loads, these auxiliary devices can be omitted. How do we understand the term "without loads"?

The design of a washing machine assumes that a pulley with a drum is connected to the motor shaft. The motor must spin the centrifuge, and when turned on, it experiences increased load, so a capacitor or "power supply" for the starting winding is required in the circuit. If the motor is intended for use in more demanding conditions, auxiliary devices that facilitate starting can be omitted.

If you've built a new device (such as a sander or apple slicer) using the motor from an old washing machine, and the motor becomes excessively hot even after short periods of use, you need to take appropriate measures. There could be several reasons for this overheating:

- broken bearings;

- reduced “gap” between the stator and the rotor (because of this, the parts constantly rub against each other);

- an incorrectly selected capacitor, namely one with an excessively large capacity.

Checking whether the capacitor is the culprit is fairly simple. Disconnect it, and the problem will become clear. If it is the capacitor, the starting device's capacitance will need to be reduced.

Some single-phase motors have three terminals instead of four. This is because the two windings are already connected to each other at one point. In any case, when removing the motor from a washing machine, be sure to examine how the motor was connected. This will help you when creating your own electrical circuit for your homemade device.

Brushed commutator motors

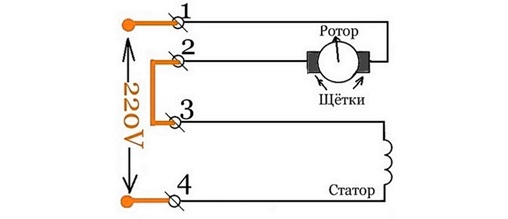

These motors are found in most washing machines produced in the last three decades. Collector motors do not have a starting winding and do not require the inclusion of a capacitor in the circuit. They are capable of “accepting” both direct current and operating on alternating current.

A commutator motor can have from 5 to 8 terminals, depending on the model, but most of them are not useful for connecting the motor outside the washing machine.

First, you need to find the leads for connecting the Hall sensor; they definitely won't be needed for further use of the motor outside the washing machine. Use a multimeter and measure the resistance of the wires. The tachogenerator windings will read approximately 60-70 ohms.

The collectors also have a thermal protection contact. It produces zero resistance. This pin can be considered "unnecessary."

To connect the commutator to the circuit, apply voltage to the free terminal of the winding. The other end is connected to the right brush. The left brush is connected to the 220-volt power supply. After these manipulations, the motor will begin to operate and rotate in one direction.

To change the direction of the electric motor's rotation, you'll need to swap the brushes. This way, the right one will be powered by the mains, while the left one will be connected to the winding wire.

Before starting, it is recommended to securely fasten the brushed motor, as it will start with a strong jerk and may damage its wiring.

In some cases, it may be necessary to regulate the speed of a commutator motor. A dimmer can be used for this purpose. However, the device's power must be greater than that of the electric motor.

You can purchase a special dimmer at stores that sell ventilation system components. These devices are used to control the speed of supply and exhaust fan motors.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment