The washing machine belt broke.

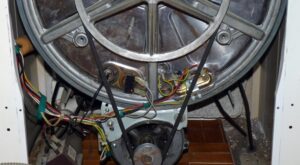

Washing machine problems, such as difficulty rotating the drum, often occur when the belt connecting the motor to the laundry compartment fails. It can stretch or slip out of its mounting grooves. Sometimes, owners are forced to repair a broken belt. The only option is to replace the damaged part. We'll discuss what to do if the belt is faulty and how to properly repair a broken one if a new one isn't available.

Washing machine problems, such as difficulty rotating the drum, often occur when the belt connecting the motor to the laundry compartment fails. It can stretch or slip out of its mounting grooves. Sometimes, owners are forced to repair a broken belt. The only option is to replace the damaged part. We'll discuss what to do if the belt is faulty and how to properly repair a broken one if a new one isn't available.

Why does the belt break or fall off?

There are various reasons for belt failure. Sometimes the part fails due to underlying problems, for example, if a pulley mount becomes loose. When it unwinds, the belt can slip. Repairmen also cite other causes of failure. A belt needs to be replaced when:

- the part wears out after reaching the end of its service life;

- the torque shaft is deformed, changing the design parameters of the engine;

- the engine mount is damaged, causing the belt tension to weaken;

- the pulley or belt is installed incorrectly, defective parts are allowed;

- the main crosspiece connecting the shaft to the tank breaks;

- As a result of bearing wear, the drum becomes skewed while rotating;

- the drum load during washing exceeds the maximum permissible load;

- the drum is loaded unevenly;

- individual parts of the structure are deformed.

In addition to the above, a washing machine belt can become damaged if the machine is rarely turned on and operated. In such situations, the belt begins to dry out and become rough.

Important! If your washing machine is equipped with a non-original belt whose parameters do not match the model, it may quickly become unusable and require replacement.

What types of belts are there?

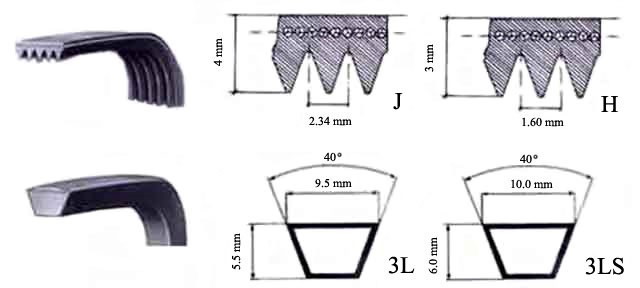

Belts come in poly V-belts (ribbed) and solid V-belts. The latter are more common. They have a trapezoidal shape and a one-piece construction. They are made from polyester cord, chloroprene rubber, and woven cotton fabrics. The advantages of these belts are strength and elasticity. A disadvantage is that they slip when tensioned too low. As a result, the rotation speed during the spin cycle decreases. Therefore, V-belts should be tensioned so that when pressed at the center, the pull is no more than 3–5 mm.

Poly V-belts are most often used on washing machines with commutator motors. They are distinguished by their multiple teeth. Regardless of the belt type, installation follows the same pattern; only the tensioning process differs. Poly V-belts are installed so that the teeth align correctly.

If the washing machine belt is deformed, it's best to replace it with a new one. Even if the part is repaired, the signs of damage will reappear after a while.

Is it possible to restore the belt?

To repair the part, you'll need two small blocks to act as a vice. They should be screwed tightly together. They should be wider than the belt. Prepare acetone, a screwdriver, screws, a pocket knife, sandpaper, and Moment adhesive. To repair a poly V-belt, follow these steps:

- clean the part with water and acetone, especially carefully cleaning the areas where gluing is planned;

- At the break points, trim off the uneven edge. Ensure that the cut is strictly perpendicular to the side edges of the belt;

- Place the piece with the wedges facing up and carefully cut 10–12 wedges along one edge. This is best done with a sharp penknife. Sand the cut area;

- then the belt is turned over with the teeth down and both edges are brought together so that 10–12 teeth are in place of the cut teeth;

- lubricate the area where the old teeth were located and press the ends of the belt tightly;

- bars are placed below and above the gluing area and secured with screws in such a way that the belt itself is not affected;

- leave the belt to dry.

Please note! This repair method shortens the belt, so it is not suitable for washing machine models that cannot adjust the belt tension by moving the motor.

It's best to entrust gluing work to a professional. Doing it yourself is not easy. V-belts can also be glued. This requires acetone, a construction stapler, and Moment adhesive. To restore the part:

- the torn areas are cut off evenly;

- Both edges are cleaned with acetone, glue is applied to them and they are tightly joined to each other;

- without moving the belt, secure the torn area with staples from a construction stapler in several places;

- When the glue is completely dry, the staples are removed.

Before installing the repaired belt in the washing machine, it's important to check the strength of the adhesive. To do this, stretch the edges of the part. It should be able to withstand the force applied. However, the lifespan of a bonded belt is much shorter than that of a new part, perhaps only a few months.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

How do I drain water from a washing machine if the belt is missing?