How to install a seal on a washing machine

What is the purpose of a washing machine's seal? This element prevents water from the drum from getting onto the bearings. Diagnosing the element and, if necessary, replacing it, are quite labor-intensive procedures that require a good deal of skill and knowledge of the washing machine's operation. You can replace the seal in your washing machine yourself, but before doing so, carefully read the manual and the main challenge is disassembling the unit.

What is the purpose of a washing machine's seal? This element prevents water from the drum from getting onto the bearings. Diagnosing the element and, if necessary, replacing it, are quite labor-intensive procedures that require a good deal of skill and knowledge of the washing machine's operation. You can replace the seal in your washing machine yourself, but before doing so, carefully read the manual and the main challenge is disassembling the unit.

What is the purpose of an oil seal?

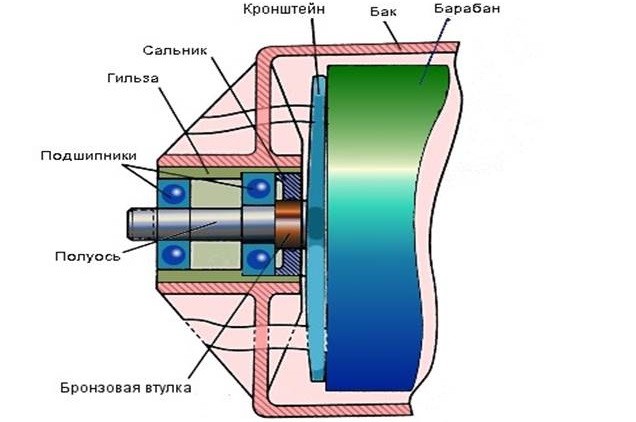

The role of this element cannot be underestimated; it acts as a kind of seal between the drum and the shaft. The seal prevents liquid from getting onto the washing machine shaft and bearings. The part looks very simple – it is a rubber ring with a certain diameter.

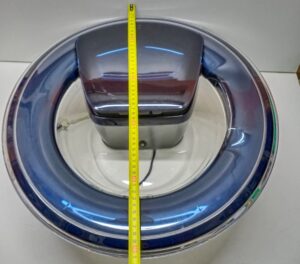

Washing machine manufacturers use seals of varying sizes when assembling their machines. The ring diameter depends on the specific washing machine model and the design features of the machine's drum. Therefore, before purchasing a component, it is recommended to disassemble the machine and remove it from the housing. This will help you determine the required seal diameter for installation.

What and how to lubricate the seal?

Due to its location in the system and the role it performs, the oil seal is constantly exposed to friction and temperature fluctuations. These effects are detrimental to the seal; after prolonged use, cracks may appear in the rubber, which will undoubtedly lead to the loss of function. Therefore, the oil seal must be protected regularly, specifically by lubricating its surface. Periodic use of special lubricants will significantly extend the service life of the element.

What lubricant should I use for my ring? When choosing the right lubricant, be sure to carefully study its properties. A high-quality lubricant must meet certain requirements.

- Be moisture-resistant. It must contain organic particles with a water-repellent effect.

- Have good heat resistance. The side of the seal adjacent to the drum will overheat during friction, so it's crucial that the lubricant retains its properties after heating.

- Do not contain aggressive components: chlorine and other elements that can damage or destroy the surface of the ring.

- It should have a thick consistency. This is necessary to ensure a tight coating of the seal rubber and oil seal bushing. Bearings can also be treated.

In response to users' questions: "What should I lubricate the part with?", we present several options for lubricants for washing machines.

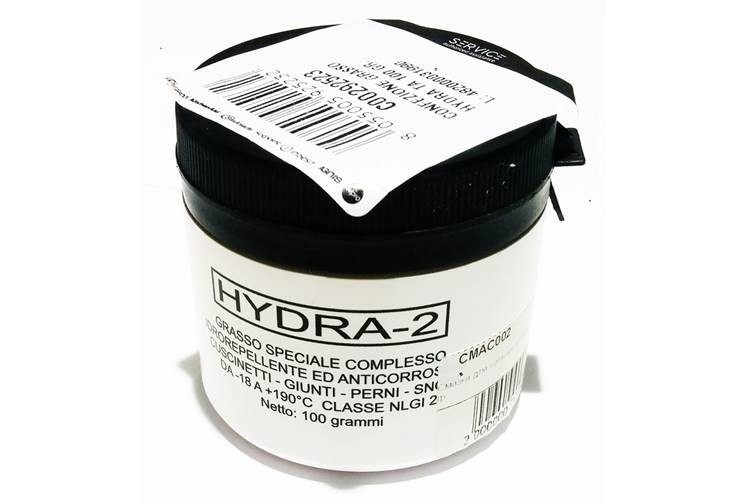

- HYDRA-2 seal grease in a syringe from an Italian manufacturer has an operating temperature of -18°C to +190°C and extends the life of the part up to 10 years. It features anti-corrosion and water-repellent properties. The average price is $1.50.

- HYDRA-2 O-ring lubricant, 50g, in a tube. Similar to the previous product, but in a different packaging. The price for a tube of the stated volume is approximately $4.20.

- SKL EBI waterproof grease is rated for temperatures up to 140°C and costs $3.80 per 50g package.

- Waterproof lithium grease SKL EBI398 is suitable for washing machine seals and bearings. It operates at temperatures from -30°C to +120°C. It has a thick consistency, does not contain aggressive substances, and offers excellent moisture resistance. The average price is $4.30 per tube.

The lubricants listed in this list have excellent performance characteristics and have been tested and recommended by professionals.

Timely treatment of the seal will increase the service life of not only the seal, but also the bearings of the washing machine.

How do you know when it's time to change the seal?

Several signs may indicate a faulty seal. First of all, an unusual noise, an unpleasant grinding sound, will be heard during the wash cycle. Other signs of a faulty seal include:

- vibration of the machine and strange knocking noise coming from inside;

- the drum is loose, you can check it yourself by turning the drum manually after washing;

- the drum stops rotating and it stops spinning completely.

Having noticed at least one of the described signs, it is better to immediately examine the condition of the oil seal. If you ignore the symptoms and continue using the machine, the likelihood that the bearings will be completely destroyed will be almost 100%.

Progress of work

To install a new seal, you'll need to completely disassemble the washing machine. This requires a standard set of tools found in every home. The disassembly procedure involves the following steps:

- detach the top cover from the housing by unscrewing the bolts holding it in place, located on the rear wall of the unit;

- Unscrew the bolts located around the perimeter of the rear part of the case and carefully remove the back wall;

- tighten the drive belt, the easiest way to do this is by rotating the shaft with your free hand;

- remove the cuff that encircles the hatch door; to do this, disconnect the metal ring that holds the rubber seal;

- disconnect the wires from the heating element and the electric motor, remembering to disconnect the ground;

- remove all hoses and pipes attached to the tank;

- separate the water intake level sensor;

- remove the shock absorbers and springs supporting the drum;

- remove the counterweights located inside the housing;

- remove the machine motor by unscrewing the mounting bolts and moving the motor forward;

- remove the tank with the drum from the machine;

- Open the tank body to gain access to the drum and use a hex key to unscrew the pulley.

Once disassembled, you'll gain access to the oil seal, bushing, and bearings. Removing the O-ring is very easy; simply pry it out with a screwdriver. Next, inspect the system components and, if replacement is necessary, install a new oil seal. To do this, it's advisable to thoroughly lubricate not only the components being installed but also the mounting surface.

It's important to install the removed ring correctly. You might wonder which way the oil seal should be installed. This is a crucial question, so carefully inspect the seal. If there are no factory marks on it, install it so that it most tightly covers the niche in which the moving elements of the bearing are located. Water must not get inside.

Should I use silicone sealant? It's useful if the washing machine's drum was non-detachable and had to be sawed open to access the seal and bearings. Sealing and re-gluing the drum will be necessary during subsequent reassembly of the machine.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment