How does Aquastop work in a washing machine?

The AquaStop system operates quite simply: special sensors detect any leaks, breaks, or overflows, and activate the washing machine's protection. A washing machine can be protected against water leaks completely or partially—different models have their own features. Let's explore how the AquaStop system works and its importance.

The AquaStop system operates quite simply: special sensors detect any leaks, breaks, or overflows, and activate the washing machine's protection. A washing machine can be protected against water leaks completely or partially—different models have their own features. Let's explore how the AquaStop system works and its importance.

Aquastop with partial protection

When studying the specifications of various automatic washing machine models, you might come across the term "partial leak protection." What does this term mean? What does the manufacturer mean by this?

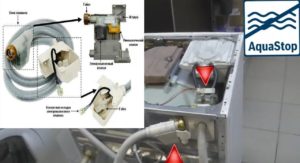

Machines that are partially leak-proof are equipped with a bottom tray with a special sensor that will detect overflow.

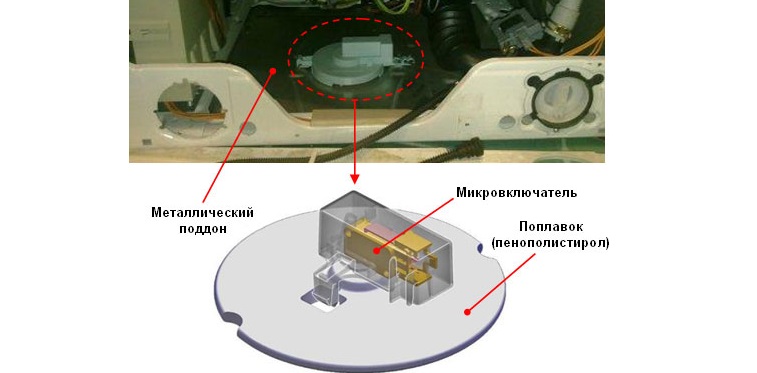

The bottom of the washing machine can be plastic or metal. It's found on washing machines with both partial and complete leak protection. Inside the tray there is a small lightweight float and a sensor with an electric switch.

When the washing machine's tub, pipes, dispenser, or hoses begin to leak, the tray fills with water. The float gradually rises, activating the electrical switch. The sensor is triggered, transmitting a signal to the control module, and the "brain" stops the wash cycle. Simultaneously, the microprocessor initiates the drain—the pump begins pumping liquid out of the machine.

Modern washing machines equipped with a display alert you to the AquaStop system's activation by displaying a corresponding error code. If this malfunction occurs, you'll need to unplug the machine, drain the water from the tray, and perform a diagnostic. It's crucial to identify and fix the cause of the problem to prevent a recurrence.

Machines with a drip tray aren't always leak-proof. Budget models may have a bottom, but without a float or sensor. In this case, the washing machine won't detect a leak. A drip tray with a microswitch is just one measure that protects your washing machine from accidental leaks. A special inlet hose is another way to protect your machine. Let's explore its distinctive features.

Protected hose design

To protect the automatic washing machine from leaks, a special inlet hose was designed. Its design features a mechanical valve and can withstand higher pressures—up to 70 bar.

If your washing machine comes standard with a regular hose, you can replace it with a sleeve with a protective flap.

When an automatic washing machine doesn't have a drip tray but does have a special inlet hose, it's also said to be only partially leak-proof. In this case, the system will respond to external leaks, while internal "failures" will remain unaddressed.

Two types of hoses, differing in design, are available in stores. The operating principle of an Aquastop is very similar, so which hose you choose is irrelevant. These are the devices:

- with a cylindrical piston, absorbent and spring;

- with a displacer, an absorbent and a pair of magnets.

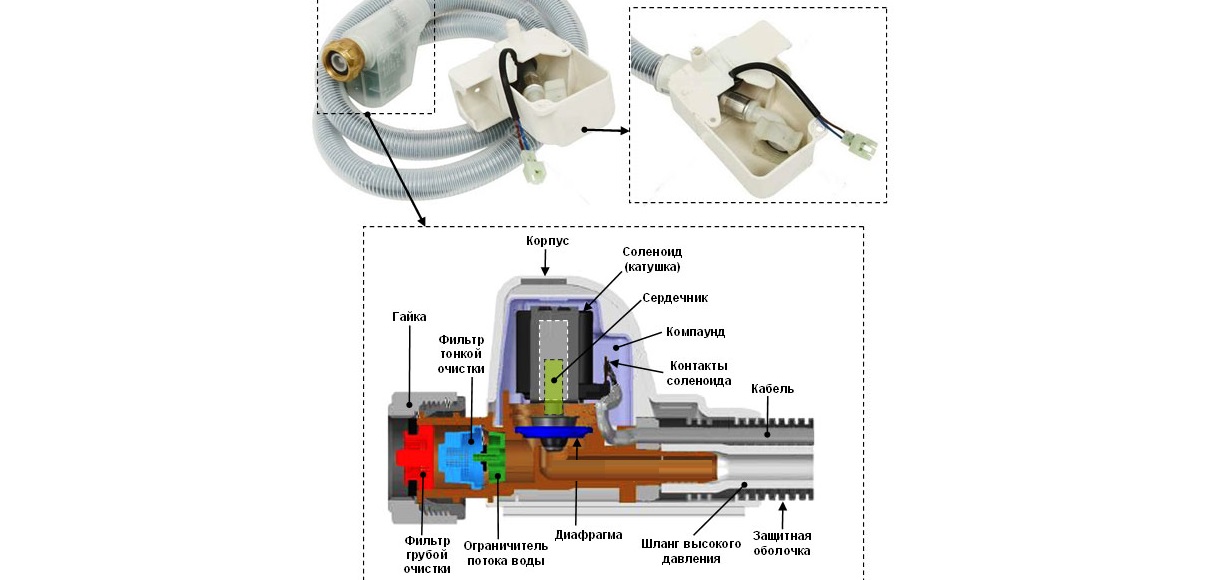

The inlet hose is "hidden" in a corrugated tube—a special plastic casing. One end connects to the washing machine body, and the other has a nut and a protective device for connecting the hose to the water outlet. How does the mechanism work?

The distinctive feature of the Aquastop hose is its plunger with a spring and absorbent material. Under normal conditions, water flows freely through the plunger, into the hose, and then into the washing machine. When the system pressure is normal, the spring does not impede the water flow.

If, for example, the inlet hose were to rupture, the protective corrugated plastic casing prevents water from escaping, trapping it inside and entering the safety device. The absorbent material in the unit would swell and stretch the spring, releasing its pressure on the plunger. This would disrupt the balance in the system, and the water supply would be shut off by the displacer.

Once the safety system is activated, the indicator light on the inlet hose will turn red. This color corresponds to the container that holds the absorbent. Therefore, if your machine suddenly stops filling, pay attention to the corrugated hose. The bright spot will give you a clue as to why the machine is stuck.

To restore the machine to working order, you will have to install a new corrugated pipe. The inlet hose cannot be used after the protection system has been activated; it will need to be replaced. Finding and purchasing the device is easy – they are sold in home appliance supermarkets.

Hoses with a safety valve are also available, controlled by two magnets. The operating principle is similar to that of a unit with an absorbent material and a spring. If a leak occurs, the valve closes and stops the water supply to the appliance.

In this situation, the plunger's position is controlled by two magnets positioned opposite each other. Their like poles face each other. When the system is balanced, the absorbent remains dry, and the distance between the magnets is small, ensuring sufficient repulsion between them.

If the hose breaks and water floods the protective block, the granules become soaked, the absorbent material expands, thereby weakening the magnetic field. Therefore, the plunger shuts off the water flow, thus stopping the liquid supply to the washing machine. There is another difference. The nut on the magnetic hose has a ratchet mechanism. This allows it to be easily screwed onto the thread of the water outlet. To tighten this nut, you need to tighten and hold the ratchet. If the absorbent material gets wet even once, the hose is also irreparable and will need to be replaced.

Inlet hose with electromagnetic valve

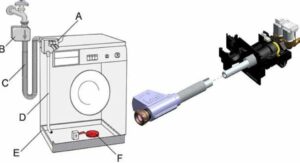

It's best to look for modern automatic machines with a complete leak-proof feature. These models, in addition to a tray with a float, also have a special inlet hose. This protects the machine from both external and internal leaks.

In machines with absolute leak protection, a special inlet hose is provided by the design and installed at the factory.

This high-pressure inlet hose is equipped with a block containing one or two solenoid valves. They are connected in series. The hose is also enclosed in a corrugated plastic sheath. This state-of-the-art hose includes the following components:

- water flow restrictor;

- coil (solenoid);

- core;

- thermoactive paste (compound);

- diaphragm;

- power cable;

- contact block.

A protective "box" is located at the end of the inlet hose that connects to the water inlet valve. The connection is tightened with a designated nut. The electromagnetic devices inside the unit are encapsulated in a compound. A power cable runs from a thermosetting polymer resin along the entire hose, ending with a terminal block that connects to the washing machine's electrical circuit.

When the hose and the machine body are protected

Let's take a look at how absolute leak protection works. Washing begins as usual: the user loads the laundry into the drum, selects the desired program, and starts the cycle. After pressing the "Start" button, power is applied to the machine's inlet solenoid valve and the inlet hose assembly.

The valves open, and water flows into the washing machine. When the machine fills to the required level, the control module signals the valves of the machine and the inlet hose, which shut off the water flow. This occurs when the washing machine is operating in normal mode.

Let's say the inlet hose cracks and starts leaking. Some water will flow into the tank, while some will remain in the hose's protective sheath. The absorbent material will become wet, and the water flow will be blocked by the valve. Liquid will also start draining from the corrugated hose under the machine, into the tray. The float will rise, the washing machine will “freeze” and the corresponding error code will appear on the display. Some models automatically activate the flush.

Sometimes the tank cracks. In this case, it's impossible to immediately notice the leak. Water will leak out of the tank, and if the machine doesn't have a drip tray with a safety sensor, flooding is inevitable. If a drip tray is installed, water will collect there. The float will rise, the sensor will be triggered, and the control module will close the solenoid valves to stop the water flow. Thanks to the coordinated operation of all safety mechanisms, flooding can be prevented.

Machines with full leak protection do have a drawback. If the solenoid burns out or the diaphragm in the inlet hose is damaged, the entire expensive hose will have to be replaced. However, these costs certainly won't be as high as the cost of repairing your own and your neighbor's flooded apartment. The AquaStop feature is a useful addition, well worth the extra cost.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment