How does the valve work in a washing machine?

Almost all modern washing machines are equipped with electromagnetic valves. These devices are responsible for filling the tank with water, acting as an advanced "faucet"—a shut-off device. However, unlike a motor or pump, valve mechanisms are virtually unknown to machine users, which often leads to their failure. We suggest you don't stay on the sidelines and explore the operating principle of a washing machine valve, its structure, and its various types. This will help you better understand your machine and save money on maintenance.

Almost all modern washing machines are equipped with electromagnetic valves. These devices are responsible for filling the tank with water, acting as an advanced "faucet"—a shut-off device. However, unlike a motor or pump, valve mechanisms are virtually unknown to machine users, which often leads to their failure. We suggest you don't stay on the sidelines and explore the operating principle of a washing machine valve, its structure, and its various types. This will help you better understand your machine and save money on maintenance.

What is this device for?

Almost all modern washing machines, regardless of price point or country of manufacture, are equipped with electromagnetic valves. These devices are found in budget models from Indesit and Ariston, as well as in expensive Samsung, Bosch, and LG models. The location and appearance of the valve mechanism may vary, but the function and operating principle remain the same.

The electromagnetic valve is an essential element of the filling system of a modern washing machine.

The main function of the inlet valve is to control the amount of water entering the washing machine's drum. Briefly, it works as follows:

- the user starts the washing program;

- the board sends a command to the valve to fill with water;

- the valve coil is activated, the membrane “opens”;

- water is taken from the water supply;

- The pressure switch controls the level of incoming water and as soon as the required volume is reached, it notifies the module;

- the board commands to stop the flooding;

- the valve is activated, the membrane closes, and the water intake stops.

In simple terms, the valve acts as a shut-off valve—a tap—in a washing machine. It starts or stops the flow of water into the tank, through the inlet hose, dispenser, and system of pipes. The device's operation is controlled by a control board.

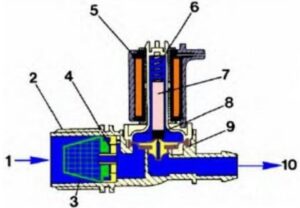

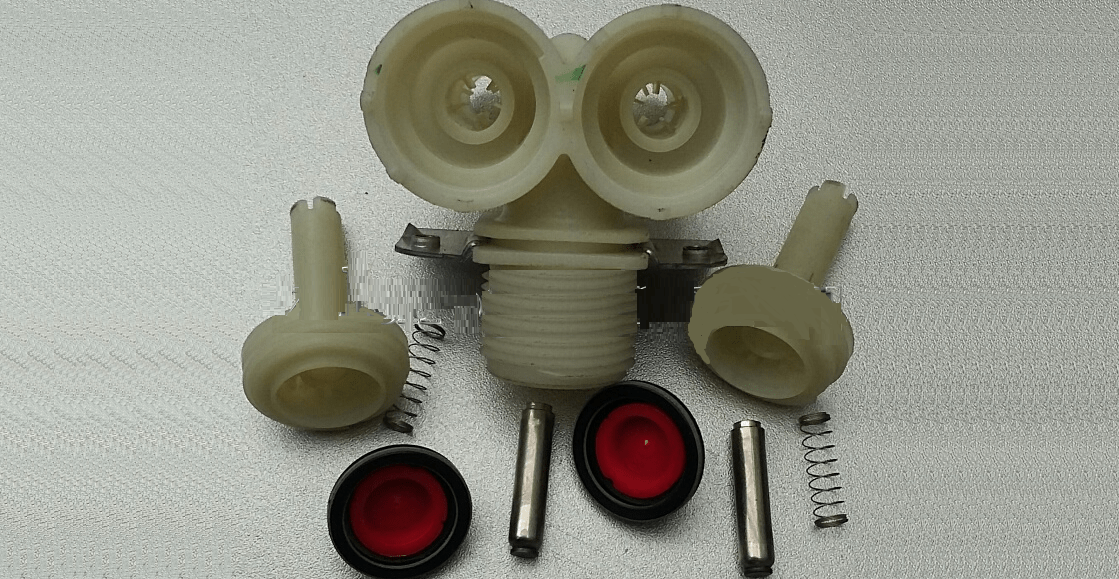

Structural elements

A closer look at the valve's design will help you understand its operation. It's a small device, white, blue, or gray, located where the inlet hose connects to the washing machine. It consists of the following parts:

- frame;

- electromagnetic coil with core;

- spring;

- a disk fixed on the core (acts as a valve, shutting off the flow of water into the machine).

The inlet valve body is made of high-temperature-resistant polymer materials, as well as brass and stainless steel. The membrane and seals and gaskets that ensure a tight seal are made of heat-resistant rubber, natural rubber, or silicone. The primary function is played by the electric magnets—solenoids—installed in the retractor coil.

The simple design of the inlet valve is constantly being refined by manufacturers. In an effort to extend the lifespan of the device and speed up water intake, companies experiment with materials, coatings, the shape, and number of coils. However, the function and operating principle of the valve mechanism remain unchanged.

How does the valve function?

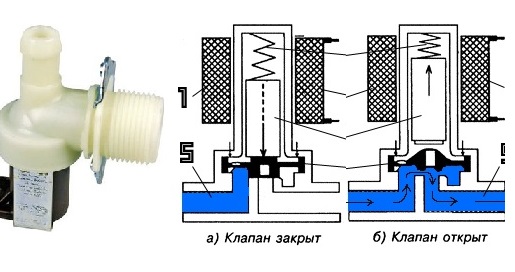

The fill valve is controlled by the control board, switching between the "open" and "closed" positions. Most of the time, the mechanism remains stationary: no power is applied to the coil, the disc is lowered, and the membrane and spring are pressed against the seat. This ensures a tight seal, preventing water from entering the appliance.

As soon as the user starts washing, the processor sends a corresponding signal to the valve coil. The electromagnets are activated, the rod is retracted together with the piston, the disk rises, opening the “entrance” to the machine. Pressurized water begins to pour into the tank.

The filling process stops after another signal from the module. It receives information from the pressure switch that the filling process has finished and cuts off the electrical current to the coil. The magnetic field weakens, the membrane is activated, the rod returns to its original position, and the "flap" closes. The system detects a full tank and starts the cycle. This process continues for every wash.

The valve requires 220V voltage and a clock frequency of 50 Hz to operate.

Some valve models have their own unique features. For example, older single-coil devices use a mechanical control lever. This lever draws water first into one compartment of the powder receptacle, and then into the other. Modern valve mechanisms have two to five coils, which simplifies filling the drum and increases the device's durability.

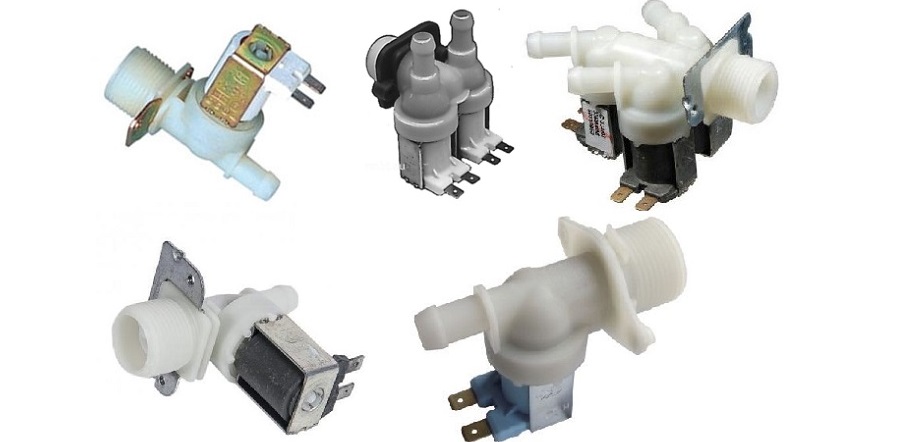

Types of devices

Almost every washing machine has water inlet valves and they operate on the same principle, but they often differ in type and other characteristics. Typically, normally closed mechanisms are installed on machines, which operate from the interaction of current and electric magnets. The devices differ in several criteria: from size and materials to the number of coils.

- Number of coils. "Old" machines were equipped with single-coil valves, while modern ones often have 2-3, and often 4 or 5 solenoids. The more magnets, the faster the device operates and the more reliable the mechanism.

- Material. The housing can be plastic or metal, and the gaskets can be made of rubber, silicone, or fluoroplastic.

- The size of the water supply fittings. Valves designed for connection to a ½-inch or ¾-inch hose are most common.

There are universal valves marked 1/90. These devices have a single outlet positioned at a right angle, while the mounting plate remains removable and can be easily adjusted to the desired angle. Due to its portability, the device is suitable for most single-coil automatic machines.

Interesting:

1 reader comment

Headings

Washing machine repair

For buyers

For users

Dishwasher

Why are there two outlets from the valve?