The belt in the washing machine is spinning.

Several years after purchasing a washing machine, users may encounter certain malfunctions. For example, they may notice that the belt on their washing machine is slipping. This problem can be fixed independently, without calling in a professional. Let's look at how the machine will behave if the drive belt has stretched. How to choose and purchase the right components, and where to begin the repair? How to install a new belt on the pulley at home?

Several years after purchasing a washing machine, users may encounter certain malfunctions. For example, they may notice that the belt on their washing machine is slipping. This problem can be fixed independently, without calling in a professional. Let's look at how the machine will behave if the drive belt has stretched. How to choose and purchase the right components, and where to begin the repair? How to install a new belt on the pulley at home?

Temporary fix for scrolling

What are the consequences of drive belt slippage? The belt, spinning on the shaft or drum wheel as the speed increases, significantly reduces the efficiency of pulse transmission from the electric motor to the centrifuge. This situation occurs regularly, at all stages of the cycle. As a result, the quality of washing and spinning is significantly reduced.

If you notice that the drive belt is spinning, it is better to replace the element immediately.

What if you really don't want to repair your "home helper" anytime soon? And you don't have the money to order and buy parts? Some machine owners resort to a trick: spraying the belt with a special aerosol to increase friction. Hi-Gear Belt Dressing spray can be purchased for $4.90. However, the effect of this spray only lasts for up to 20 washes, meaning you'll have to disassemble the machine and repeat the procedure about once a month.

Rosin can temporarily solve the slippage problem. A small block of it can be purchased at any hardware store for just $0.20–$0.30. Rub this piece onto the inside of the drive belt (the working surface that "contacts" the pulley).

The difference in cost between these two products is significant. Rosin is even more effective, improving friction without staining the belt. The rubber stays dry, preventing dust and debris from sticking to its surface.

The effect of rosin treatment on the drive belt lasts for up to 25 washes. This should give you enough time to get to the nearest specialty store or order parts for your washing machine online. Unfortunately, in some cases, belt slippage may be caused not by simple wear and tear or stretched rubber, but by more serious issues. For example, a change in the shaft shape, broken spider, or bearings. This will need to be checked.

How to install the belt correctly?

If the rubber band is slipping or even slipping off the pulley, don't immediately call a service center. Of course, if the machine is still under warranty and the repair is free, it's best to call a technician, but in other cases, you can fix the problem yourself. To tension the drive belt, you don’t need any special knowledge, just a little patience and skill.

The first time the strap comes off, you can try simply tightening it back. It's likely to serve you faithfully for another year. If the strap comes off again, you'll need to replace it.

To access the drive belt and assess its condition, you need to:

- disconnect the washing machine from the power supply;

- close the shut-off valve on the pipe that controls the water supply;

- Move the machine away from the wall. You will need free access to its rear;

- detach the inlet hose and drain sleeve from the washing machine body;

- Remove the screws securing the back panel. Some machines will require removing the housing cover first;

- Find the drive belt. It will be tensioned on the drum pulley. If the rubber band has broken, look for it on the floor, under the machine.

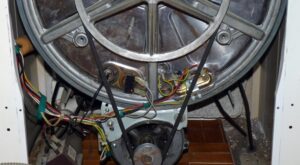

On all automatic machines with brushed motors, the belt is located in one place—stretched between the drum pulley and the motor. If the belt isn't visible here, it's probably fallen off and is lying underneath the appliance.

To assess the condition of the drive belt, it is necessary to compare its original dimensions with the actual ones.

To do this, you need to find the factory stamp on the elastic. The first four digits of the marking will indicate the belt's initial dimensions—its "normal" diameter in millimeters. All that's left to do is measure the circumference and compare both values.

A slight deviation from factory parameters is considered normal. If the belt has stretched more than 20 mm, it must be changed. This type of rubber seal is no longer suitable for installation in the washing machine—it will constantly fall off. You can purchase spare parts for your automatic washing machine at local stores or online. When purchasing parts, it's important to refer to the model and serial number of your washing machine. Even better, show the seller the removed rubber seal so they can accurately select a replacement.

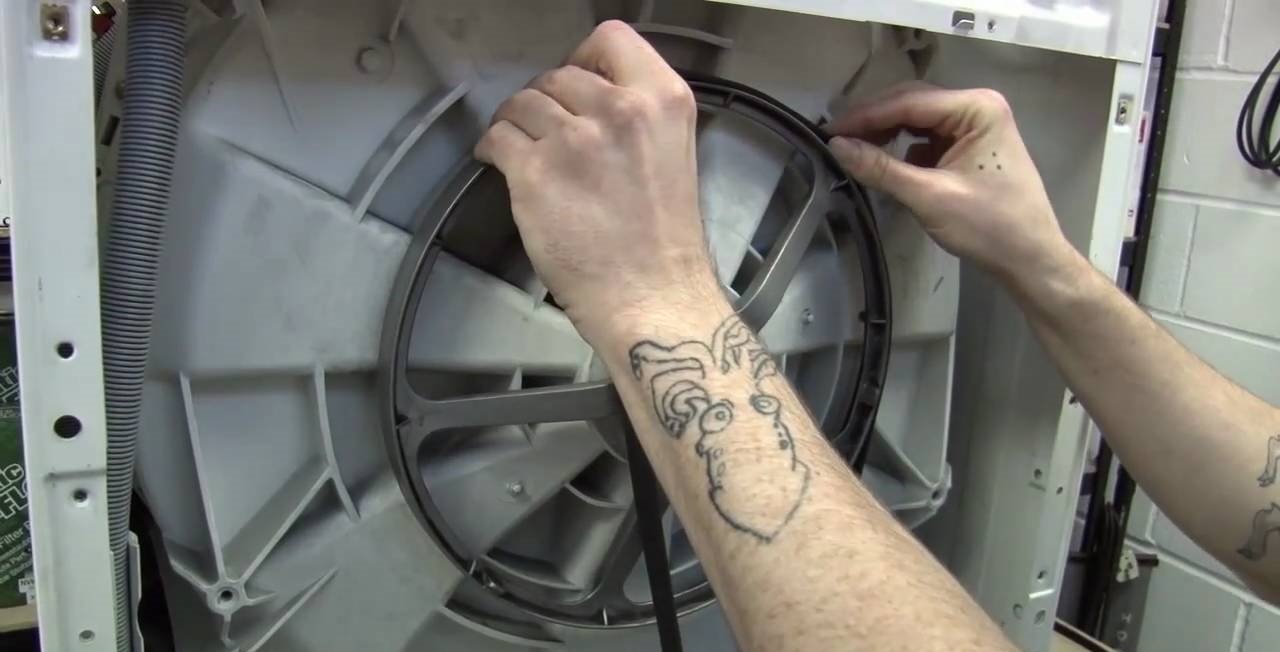

To repair the machine, you need to replace the belt. First, place the rubber band on the motor pulley, then gradually tighten it onto the drum "wheel." With your free hand, rotate the larger pulley from right to left.

It's important to follow the belt tensioning sequence, starting from the bottom and only then working on the drum pulley. If you're too weak to tighten the belt yourself, it's best to have a family member help. Some washing machines have quite tight belts, so be patient. Once you're done, check to see if the belt is securely in place. Turn the pulley—the wheel should be tight. If all is well, you can reassemble the machine.

- secure the back panel by screwing in all the previously removed bolts;

- put the “cover” back in place and secure it with screws.

Next, connect the drain and water inlet hoses to the machine and move the machine back to its original location. After that, all that's left to do is test the machine by running an empty wash cycle. If the drum rotates as it should, the belt replacement is complete.

The belt is slipping and falling off regularly again.

If it's only been a short time since installing a new drive belt and it starts slipping or spinning again, you'll need to dig deeper. The rubber shouldn't stretch that quickly if all the machine components are functioning properly, so there are likely other issues within the system.

A more in-depth diagnosis of the automatic transmission will be necessary if the new drive belt stretches and falls off after just 3 months of installation.

Constant stretching of the elastic band can be caused by:

- Pulley play. In this situation, the belt isn't to blame. If the drum wheel is loose, tighten its screw more firmly—this will help improve the element's fit. Sometimes, a complete pulley replacement may be necessary;

- Insufficient motor mounting. The motor is securely fastened to the washing machine at the factory. During operation, the motor may become loose. During operation, the machine constantly vibrates, causing the screws to loosen, which can cause serious problems with the drive mechanism. Tightening the motor bolts can solve this problem.

- A change in the shape of the shaft or pulley. This can occur after a poorly completed repair. Sometimes, when replacing one part of the machine, technicians damage other components. If the drum wheel is only slightly deformed, you can try to straighten it. Ideally, however, it's best to replace the damaged components immediately.

- Damage to the universal joint. This is a very rare problem, but it shouldn't be ignored. The part must be replaced; it can't be repaired. Ignoring the problem will inevitably lead to drum imbalance, which will lead to increased repair costs.

- Failed bearings. Broken rings cause distortion in the system, which will undoubtedly lead to the drive belt constantly slipping. The drum-tank assembly will have to be disassembled and the damaged components, along with the seal, replaced.

Repeated slipping of the drive belt is sometimes caused by its incorrect installation.

When tightening the rubber band onto the pulley, make sure it fits securely in the grooves. If you neglect this recommendation, the belt may fall off after just a few days. Then you'll have to disassemble the machine again and reinstall the element onto the "wheel."

Furthermore, a new belt that's not suitable for your specific washing machine model can quickly stretch and fall off. That's why it's important to buy a replacement for the old part. Don't forget to tell the seller the name and serial number of your washing machine. Even better, show them the factory markings on the old belt.

In most cases, you can fix a washing machine with a slipping drive belt yourself. Typically, it's as simple as replacing the rubber seal. Sometimes, you'll need to tighten the motor or pulley fasteners more tightly. In some cases, replacing the drum spider or bearing assembly alone will solve the problem.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment