How to check the motor of a Bosch washing machine?

If your Bosch washing machine remains stationary after pressing the "Start" button and filling with water, it means the drum is unable to spin. The cause of the slowdown cannot be immediately determined; a comprehensive diagnosis will be required, from the drive belt to the circuit board and motor. It's best not to attempt to tinker with the control module at home—it's too risky, but almost anyone can handle the motor without any special training. Simply follow the instructions.

If your Bosch washing machine remains stationary after pressing the "Start" button and filling with water, it means the drum is unable to spin. The cause of the slowdown cannot be immediately determined; a comprehensive diagnosis will be required, from the drive belt to the circuit board and motor. It's best not to attempt to tinker with the control module at home—it's too risky, but almost anyone can handle the motor without any special training. Simply follow the instructions.

Removing and testing the motor

Almost anyone can check the motor of a Bosch washing machine, but before starting work, it is recommended to familiarize yourself with the “object”. All Bosch models are equipped with compact and powerful collector motors, which, unlike inverter motors, require a drive belt. The rubber band connects the drum pulley and the engine, allowing the mechanism to spin.

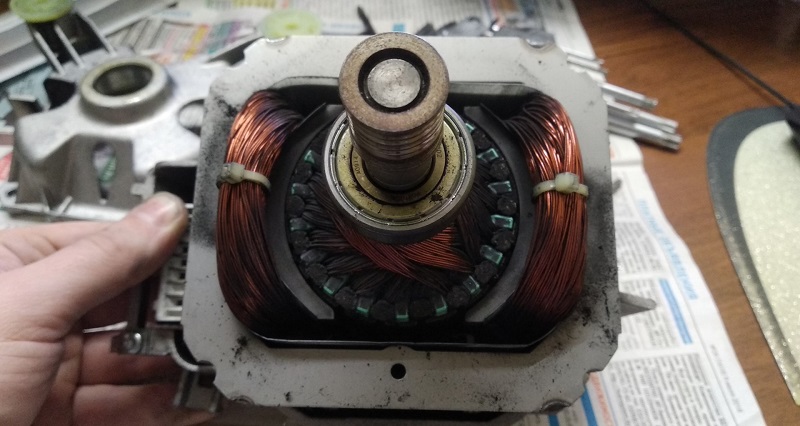

The motor's internal structure consists of a rotor, stator, and winding. Brushes are attached to the housing, and next to them is a tachogenerator that controls the acceleration speed. Once you've become familiar with the motor's structure, you can begin testing it. However, before testing, you'll need to remove the device from the washing machine.

We proceed as follows:

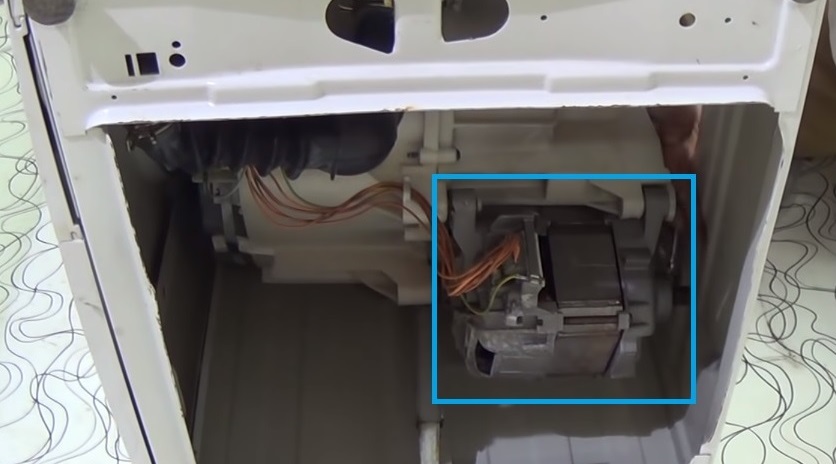

- remove the back wall of the case by unscrewing the corresponding fasteners;

- we disconnect the drive belt, while tightening it, turning the pulley with the other hand;

- we disconnect the connected wiring;

- We loosen the retaining bolts and, rocking it, remove it from its seat.

Before disassembling the washing machine, please read the manufacturer's instructions and electrical documentation.

Now we move on to checking the motor. We connect a wire from the rotor winding to the stator, and then apply 220 volts to the circuit. If the motor starts to rotate, it's working properly; if it doesn't, it's malfunctioning.

Testing the motor with voltage also has its drawbacks. For example, it's impossible to test the motor's ability to operate at different speeds. Another drawback is the high risk, as a direct connection can cause the device to overheat and subsequently short-circuit. However, the risk of damage to the electric motor can be reduced by connecting a heating element, which will heat up during a current leak, thereby protecting the motor.

Motor testing isn't limited to just one check. It's also necessary to assess the condition of the brushes, fins, and windings.

Be sure to check the brushes.

The electric brushes are often the culprit when the drum slows down. There are two of them, mounted on either side of the motor, and they smooth out the frictional force emanating from the device. These are rectangular metal "casings" containing carbon tips. During use, the “coals” wear out and need to be replaced.

The technician's job is to check the length of the carbon tips. To do this, the brushes are removed and inspected according to the following diagram:

- we unscrew the screws holding the cases;

- we compress the springs and unhook the electric brushes;

- we unclip each case;

- We measure the length of the "coals".

The minimum length of the brushes is 1.5-2 cm. If the brushes are worn more than necessary, they need to be replaced. Replace parts only in pairs, even if the other part is relatively undamaged. Replacements are selected based on the engine or washing machine serial number. To avoid choosing the wrong components, it is recommended to bring the parts to the store with the parts removed.

Other engine parts

The lamellas and windings also require inspection. The lamellas are metal plates that transmit electricity to the rotor. They are glued directly to the shaft, but over time they can peel off, disrupting current transmission. If the peeling is minor, grinding is recommended; if it is severe, the motor must be replaced.

The winding is next. If there's a break, a short circuit occurs, the motor overheats, the thermistor trips, and the mechanism shuts down. The wiring's integrity is checked with a multimeter:

- turn on resistance measurement;

- we place the feeler gauges on the engine shaft;

- We compare the result with the norm of 20-200 Ohms (if less than 20, there is a short circuit, if more than 200, there is an open circuit).

The stator is also tested, but only with a buzzer. If a winding break is detected, repairs are not enough – the motor must be replaced.

Interesting:

Readers' comments

Headings

Washing machine repair

For buyers

For users

Dishwasher

Add a comment